Izitini Zendwangu Ye-Alumina

Inkomba Yomkhiqizo

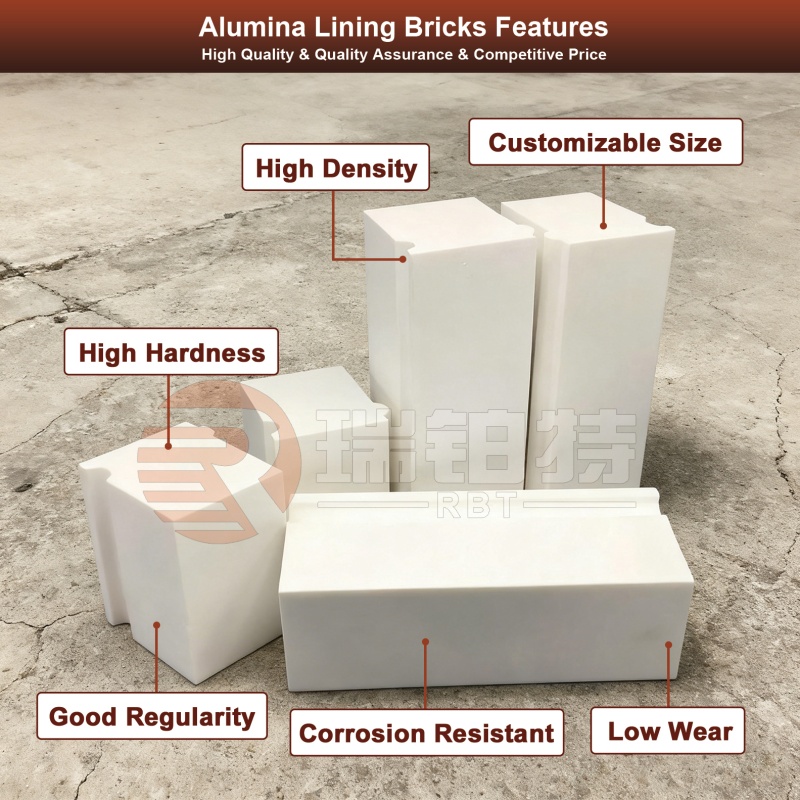

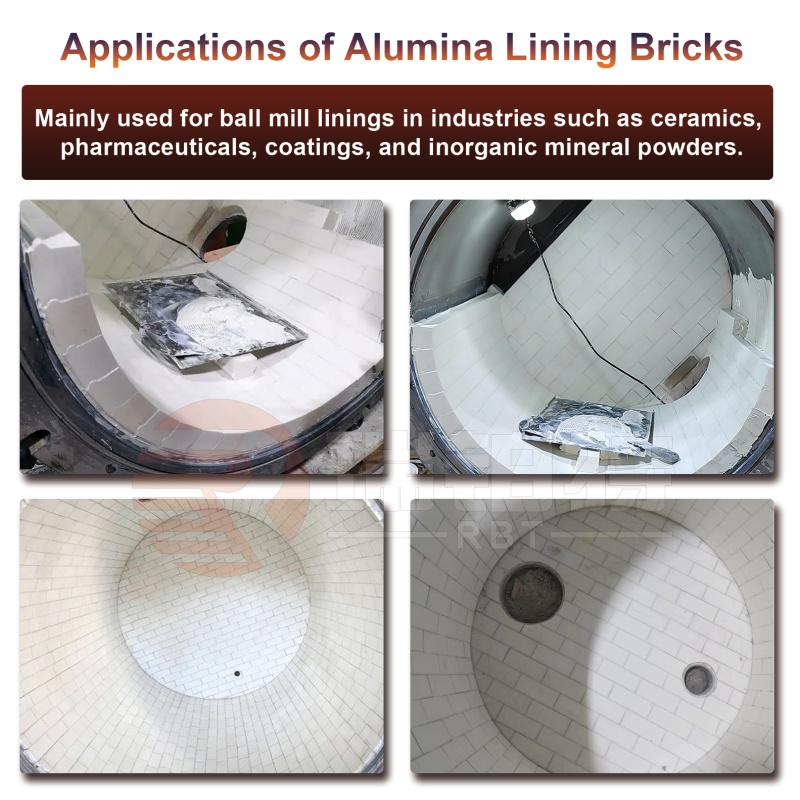

Izitini ze-alumina ezingagugiZenziwe ngempuphu ye-alumina esezingeni eliphezulu ehlanzekile kakhulu, futhi zingasetshenziswa ekugayeni ama-glaze namathayili e-ceramic. Lo mkhiqizo unezici zobulukhuni obuphezulu, ukuminyana okuphezulu, ukuguguleka okuncane, ukuhleleka okuhle, kanye nokumelana nokugqwala. Zisetshenziswa njengezinto zokuvala ezingagugi zemishini yokugaya ibhola, zisetshenziswa kabanzi ezimbonini ezifana ne-ceramics, usimende, uwoyela, imibala, amakhemikhali, imithi, ukumbozwa, kanye nempuphu yamaminerali angaphili, zithuthukisa ngempumelelo ukusebenza kahle kokugaya, zinciphisa izindleko zokugaya, futhi zinciphise ukungcola komkhiqizo.

Inkomba Yomkhiqizo

| Into | I-AM92 | I-AM95 | I-AME95 | I-AM99 |

| I-Al2O3(%) | 92±0.5 | 95±0.5 | 95±0.5 | 99±0.5 |

| Amandla Okugoba (MPa) | ≥220 | ≥250 | ≥300 | ≥330 |

| Amandla Okucindezela (MPa) | ≥1050 | ≥1300 | ≥1600 | ≥1800 |

| Ukuqina Kokuphuka (MPam1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.1 |

| Ukuqina kweRockwell (HRA) | ≥82 | ≥85 | ≥88 | ≥88 |

| Ubuningi Bokulahlekelwa (cm³) | ≤0.5 | ≤0.2 | ≤0.3 | ≤0.11 |

| Ubuningi (g/cm³) | 3.6 | 3.65 | 3.7 | 3.88 |

Ubukhulu Bezinkomba

| Isitini Sokumboza (Asinciphile) | ||||||

| Ububanzi (mm) | 35 | 40 | 50 | 60 | 70 | 90 |

| Ububanzi (mm) | 50 | 50 | 50 | 50 | 50 | 50 |

| L(mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Isitini Sokumboza (Esithambile) | ||||||

| Ububanzi (mm) | 35 | 40 | 50 | 60 | 70 | 90 |

| Ububanzi (mm) | 45/50 | 45/50 | 45/50 | 45/50 | 45/50 | 45/50 |

| L(mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Isitini Sokumboza (Esinganciphisiwe Ingxenye) | ||||||

| Ububanzi (mm) | 35 | 40 | 50 | 60 | 70 | 90 |

| Ububanzi (mm) | 50 | 50 | 50 | 50 | 50 | 50 |

| L(mm) | 75 | 75 | 75 | 75 | 75 | 75 |

| Isitini Sokulenga (Esinciphile) | ||||||

| Ububanzi (mm) | 35 | 40 | 50 | 60 | 70 | 90 |

| Ububanzi (mm) | 45/50 | 45/50 | 45/50 | 45/50 | 45/50 | 45/50 |

| L(mm) | 75 | 75 | 75 | 75 | 75 | 75 |

| Isitini Sokumboza (Esincane-esinganciphisi) | ||||||

| Ububanzi (mm) | 35 | 40 | 50 | 60 | 70 | 90 |

| Ububanzi (mm) | 25 | 25 | 25 | 25 | 25 | 25 |

| L(mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Isitini Sokumboza (Esincane Esithambile) | ||||||

| Ububanzi (mm) | 35 | 40 | 50 | 60 | 70 | 90 |

| Ububanzi (mm) | 22.5/25 | 22.5/25 | 22.5/25 | 22.5/25 | 22.5/25 | 22.5/25 |

| L(mm) | 150 | 150 | 150 | 150 | 150 | 150 |

Ukumbiwa Kwezimayini Nokusetshenzwa Kwensimbi:Izigayo zebhola, izihlungi, ama-chute, kanye nezindawo zokufaka ama-tapping for metallurgical furnaces, ezimelana nokuguguleka okukhulu kokugaya i-ore kanye ne-slag encibilikisiwe;

Izinto Zokwakha:Izigayo zebhola zesamente/ze-ceramic, amapayipi omoya e-samente kiln, ama-port okuphakelayo esithando esincibilikisa ingilazi, njll., afanele izimo zokugaya/zokuhlanza izinto ezishisa kakhulu;

Izimboni Zamakhemikhali Nezemithi:Ama-reactor, amapayipi odaka, kanye nezinhlaka zokugaya zemishini yokwelapha, ezimelana nokugqwala kwe-asidi kanye ne-alkali kanye nezinto ezingangcolisi;

Imboni Yamandla:Izigayo zamalahle ezitshalweni zamandla ezishisayo, amapayipi okuhambisa umlotha ondizayo, kanye namapayipi okukhipha i-slag ezindaweni zokushisa ezisebenzisa imfucuza zibe amandla, ezingagugi ngenxa yamalahle/i-slag;

Abanye:Izingxenye ezingagugi zemishini yokugaya embozwayo, amapayipi okuhambisa amakhemikhali amalahle, kanye nemishini yokwelapha imfucuza eqinile yemvelo.

Iphrofayela Yenkampani

I-Shandong Robert New Material Co., Ltd.itholakala eDolobheni laseZibo, eSifundazweni saseShandong, eShayina, okuyisisekelo sokukhiqiza izinto ezingaphili. Siyibhizinisi lesimanje elihlanganisa ucwaningo nentuthuko, ukukhiqiza, ukuthengisa, ukuklama nokwakha ihhavini, ubuchwepheshe, kanye nezinto ezingaphili kwamanye amazwe. Sinemishini ephelele, ubuchwepheshe obuthuthukisiwe, amandla aqinile obuchwepheshe, ikhwalithi yomkhiqizo enhle kakhulu, kanye nedumela elihle. Ifektri yethu ihlanganisa amahektha angaphezu kwama-200 kanti umkhiqizo waminyaka yonke wezinto ezingaphili ezimile ungaba amathani angama-30000 kanti izinto ezingaphili ezimile zingamathani ayi-12000.

Imikhiqizo yethu eyinhloko yezinto eziphikisayo ifaka phakathi: izinto eziphikisayo ze-alkaline; izinto eziphikisayo ze-aluminium silicon; izinto eziphikisayo ezingabunjwanga; izinto eziphikisayo zokushisa ezivikelayo; izinto ezikhethekile eziphikisayo; izinto eziphikisayo ezisebenzayo zezinhlelo zokuphonsa eziqhubekayo.

imibuzo ejwayelekile ukubuzwa

Udinga usizo? Qiniseka ukuthi uvakashela izinkundla zethu zokusekela ukuze uthole izimpendulo zemibuzo yakho!

Singumkhiqizi wangempela, imboni yethu igxile ekukhiqizeni izinto eziphikisayo iminyaka engaphezu kwengu-30. Sithembisa ukuhlinzeka ngentengo engcono kakhulu, insizakalo engcono kakhulu yangaphambi kokuthengisa kanye neyangemva kokuthengisa.

Kuyo yonke inqubo yokukhiqiza, i-RBT inohlelo oluphelele lwe-QC lokwakheka kwamakhemikhali kanye nezakhiwo zomzimba. Futhi sizohlola izimpahla, futhi isitifiketi sekhwalithi sizothunyelwa nezimpahla. Uma unezidingo ezikhethekile, sizozama konke okusemandleni ethu ukuze sizilungiselele.

Kuye ngobuningi, isikhathi sethu sokulethwa sihlukile. Kodwa sithembisa ukuthumela ngokushesha ngangokunokwenzeka ngekhwalithi eqinisekisiwe.

Vele, sinikeza amasampula amahhala.

Yebo, vele, wamukelekile ukuvakashela inkampani ye-RBT kanye nemikhiqizo yethu.

Akukho mkhawulo, singakunikeza isiphakamiso nesixazululo esingcono kakhulu ngokwesimo sakho.

Sesineminyaka engaphezu kwengu-30 senza izinto eziphikisayo, sinokusekelwa okuqinile kwezobuchwepheshe kanye nokuhlangenwe nakho okucebile, singasiza amakhasimende ukuklama ama-kiln ahlukene futhi anikeze isevisi eyodwa.