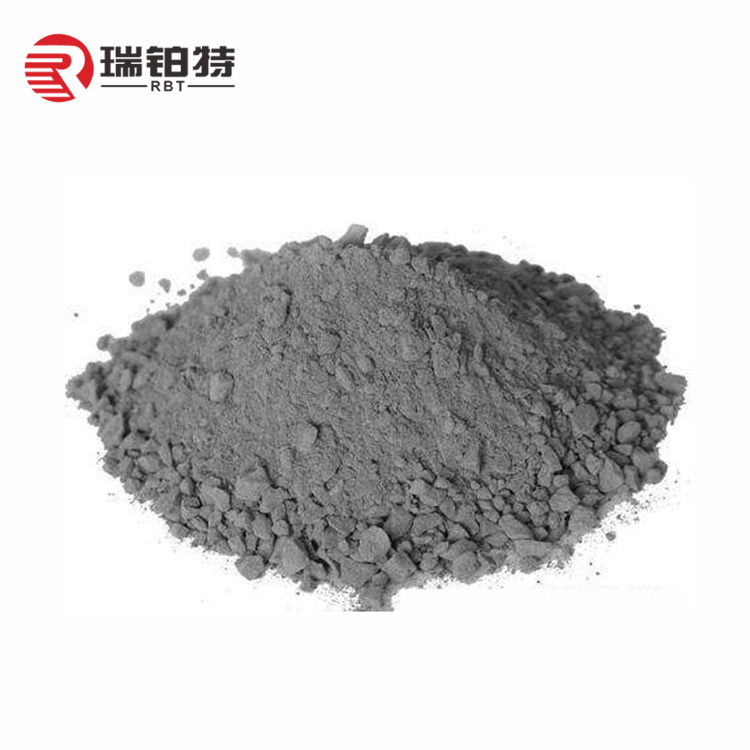

High Alumina Refractory Castable

Ulwazi Lomkhiqizo

| Igama Lomkhiqizo | I-Refractory Castable |

| Izigaba | I-Low Cement Castable/Amandla Aphakeme Angasakazwa/I-Alumina Esezingeni Eliphezulu Engasakazwa/Engasindi Okusakazwayo |

| Ukwakheka | Ama-refractory aggregates, ama-powder nama-binders |

| Izici | 1.Easy Construction, 2.Ukumelana okuhle ne-Slag, 3.Ukumelana nokugqwala okuhle, 4.Ukumelana Nomlilo Okuhle, 5.Ukonga Amandla Nokuvikelwa Kwemvelo. |

| Izinhlelo zokusebenza | Isetshenziswa Kabanzi Ezimbonini Zokushisa Eziphakeme Ezihlukahlukene. |

| Imikhiqizo | I-Low Cement Castable | High Amandla Castable |

| Incazelo | Izinsimbi zikasimende eziphansi zibhekisela ezintweni ezisansimbi ezintsha ezinesibophezelo esincane kakhulu sikasimende.Okuqukethwe kukasimende ezinsimbini ezincibilikayo ezincibilikayo kuvamise ukuba ku-15% kuya ku-20%, kanti okuqukethwe usimende kuma-castable usimende aphansi cishe ku-5%, kanti amanye aze ancishiswe abe ngu-1% kuya ku-2%. | Amandla aphezulu angagqoki angagqoki ahlanganiswe amandla aphezulu, izingxube zamaminerali, i-aggregate yamandla aphezulu kanye ne-anti crack kanye ne-ejenti engagugi. |

| Izici | Ukumelana nokushaqeka okushisayo, ukumelana ne-slag, nokumelana nokuguguleka kuthuthukiswa kakhulu, kudlula izitini eziphikisayo ezifanayo. | Amandla aphezulu, ukumelana nokugqokwa okuphezulu, ukumelana nomthelela, ukumelana nokuguguleka, ukumelana nowoyela ukungena, ukulawulwa komumo ngokunganaki, ubuqotho obuqinile, ukwakhiwa okulula, ukusebenza kahle kokwakhiwa, kanye nesevisi ende. |

| Izinhlelo zokusebenza | I-1.I-Lining yezithando ezihlukahlukene zokushisa ukushisa, ukushisa okushisa, ama-shaft kilns, ama-rotary kilns, izembozo zomlilo kagesi, ama-tapholes omlilo oqhuma; I-2.Ama-castable aphansi kasimende azigelezayo afaneleka ekushiseni okuphezulu kwesibhamu se-spray gun for spray metallurgy kanye ne-petrochemical catalytic cracking reactors I-Wear-resistant lining, i-lining yangaphandle yokushisa isithando somlilo ipayipi epholile yamanzi, njll. | Ungqimba lwe-slag sluice olungagugi ulwelwesi,i-ore trough, i-spout yamalahle, i-hopper nesilo ku-metallurgy, amalahle, amandla ashisayo, amakhemikhali,usimende nezinye izimboni, kanye nesithando somlilo esiqhumayo sixuba isisele, isisele se-sintering, i-feeder, i-pelletizer, njll. |

| Imikhiqizo | High Alumina Castable | I-Lightweight Castable |

| Incazelo | Izinsimbi eziphezulu ze-alumina ziyi-refractoryama-castables enziwe ngezinto zokusetshenziswa kwe-alumina ephezulunjengama-aggregates nama-powders, bese wengezangezibophezelo. | I-lightweight castable ene-low bulk density yenziwe ngosimende we-aluminate, i-alumina ephezulu yezinto ezinhle, i-ceramsite, nezithasiselo. |

| Izici | Inamandla okusebenza aphezulu kanye nokungaguquguquki okuhle kokushisayo, ukumelana nemihuzuko nezinye izici. | Ukuminyana kwenqwaba ephansi, ukuguquguquka okuncane kokushisa, umphumela omuhle wokufakwa kwe-thermal, amandla okucindezela aphezulu, ukumelana nokugqwala kwe-asidi negesi ene-asidi, ukwahlukanisa ukushisa, ukwahlukanisa okushisayo, nokumuncwa kwamanzi aphansi. |

| Izinhlelo zokusebenza | Isetshenziswa kakhulu njengolwelwesi lwangaphakathi lwama-boilers, izitofu zokushisa ezishisayo zesithando somlilo, izitofu zokufudumeza, izitofu ze-ceramic nezinye iziko. | I-castable engasindi ingasetshenziselwa ungqimba olushisayo olushisayo lwesithando somlilo sezimboni kanye nemishini esetshenziselwa ulwelwesi lwamapayipi egesi asezingeni eliphezulu. |

Inkomba Yomkhiqizo

I-Hot Blast Stove

Ikhishi Lomhubhe

I-Rotary Kiln

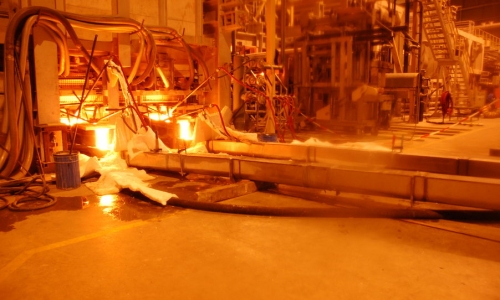

Imboni ye-iron nensimbi: isetshenziselwa kakhulu ukugcinwa nokunamathisela izithando zikagesi ze-arc, izithando zokwenza insimbi, amaladi nezinye izinto zokusebenza.

Imboni yensimbi engeyona ayoni: isetshenziselwa ukuphetshwa kanye nokulungisa ithusi, i-aluminium, i-zinc, i-nickel nezinye iziko neziguquli zokuncibilikisa insimbi ezingenayo ayoni.

Imboni yengilazi: isetshenziselwa ukunakekela kanye nomsebenzi wokunamathisela weziko lezingilazi, iziko lokuthungatha nezinye izinto zokusebenza.

| Igama Lomkhiqizo | I-Low Cement Castable | |||||

| INDEX | I-RBTZJ-42 | I-RBTZJ-60 | I-RBTZJ-65 | I-RBTZJS-65 | I-RBTZJ-70 | |

| I-Working Limit Temperature | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Ukuminyana kwenqwaba(g/cm3)110℃×24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Amandla Okugoba Okubandayo110℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Amandla Okuchotshozwa Okubandayo(MPa) ≥ | 110℃×24h | 25 | 30 | 35 | 35 | 40 |

| CT℃×3h | 50 1300℃×3h | 55 1350℃×3h | 60 1400℃×3h | 40 1400℃×3h | 70 1400℃×3h | |

| Ushintsho Lomugqa Ongunaphakade@CT℃×3h(%) | -0.5~+0.5 1300 ℃ | -0.5~+0.5 1350 ℃ | 0~+0.8 1400 ℃ | 0~+0.8 1400 ℃ | 0~+1.0 1400 ℃ | |

| I-Thermal Shock Resistance (1000℃ amanzi) ≥ | ― | ― | ― | 20 | ― | |

| I-Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| I-CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| I-Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Igama Lomkhiqizo | High Amandla Castable | |||||

| INDEX | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Izinga lokushisa elilinganiselwe lokusebenza(℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ Ukuminyana Ngenqwaba(g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| I-Modulus of Rapture (MPa) ≥ | 110℃×24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100℃×3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400℃×3h | 8.5 1300℃×3h | 9 | 9.5 | 10 | 15 | |

| Amandla Okuchotshozwa Okubandayo(MPa) ≥ | 110℃×24h | 35 | 40 | 40 | 45 | 60 |

| 1100℃×3h | 40 | 50 | 45 | 50 | 70 | |

| 1400℃×3h | 45 1300℃×3h | 55 | 50 | 55 | 100 | |

| Ushintsho Lomugqa Ongunaphakade(%) | 1100℃×3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400℃×3h | -0.45 1300℃×3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| I-Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| I-CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| I-Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Igama Lomkhiqizo | High Alumina Castable | ||||||

| INDEX | I-Al2O3(%)≥ | I-CaO(%)≥ | I-Refractoriness(℃) | I-CT℃×3h PLC ≤1% | 110℃Ngemva Kokomisa (MPa) | ||

| I-CCS | MOR | ||||||

| I-Clay Bonded | I-NL-45 | 45 | ― | 1700 | 1350 | 8 | 1 |

| I-NL-60 | 60 | ― | 1720 | 1400 | 9 | 1.5 | |

| I-NL-70 | 70 | ― | 1760 | 1450 | 10 | 2 | |

| Usimende Uboshiwe | I-GL-42 | 42 | ― | 1640 | 1350 | 25 | 3.5 |

| I-GL-50 | 50 | ― | 1660 | 1400 | 30 | 4 | |

| I-GL-60 | 60 | ― | 1700 | 1400 | 30 | 4 | |

| I-GL-70 | 70 | ― | 1720 | 1450 | 35 | 5 | |

| I-GL-85 | 85 | ― | 1780 | 1500 | 35 | 5 | |

| I-Low Cement Bonded | I-DL-60 | 60 | 2.5 | 1740 | 1500 | 30 | 5 |

| I-DL-80 | 80 | 2.5 | 1780 | 1500 | 40 | 6 | |

| I-Phosphate Bonded | LL-45 | 45 | ― | 1700 | 1350 | 20 | 3.5 |

| I-LL-60 | 60 | ― | 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | ― | 1780 | 1500 | 30 | 5 | |

| I-Sodium Silicate Bonded | I-BL-40 | 40 | ― | ― | 1000 | 20 | ― |

| Igama Lomkhiqizo | I-Lightweight Castable | ||||||

| Izinga lokushisa elilinganiselwe lokusebenza | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Ukuminyana Ngenqwaba(g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| I-Modulus of Rapture (MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100℃×3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Amandla Okuchotshozwa Okubandayo(MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100℃×3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | ― | ― | 15 | 22 | 14 | ||

| Ushintsho Lomugqa Ongunaphakade(%) | 1100℃×3h | -0.65 1000℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| I-Thermal Conductivity (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| I-Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| I-Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Isicelo

Iphakheji&Isitolo