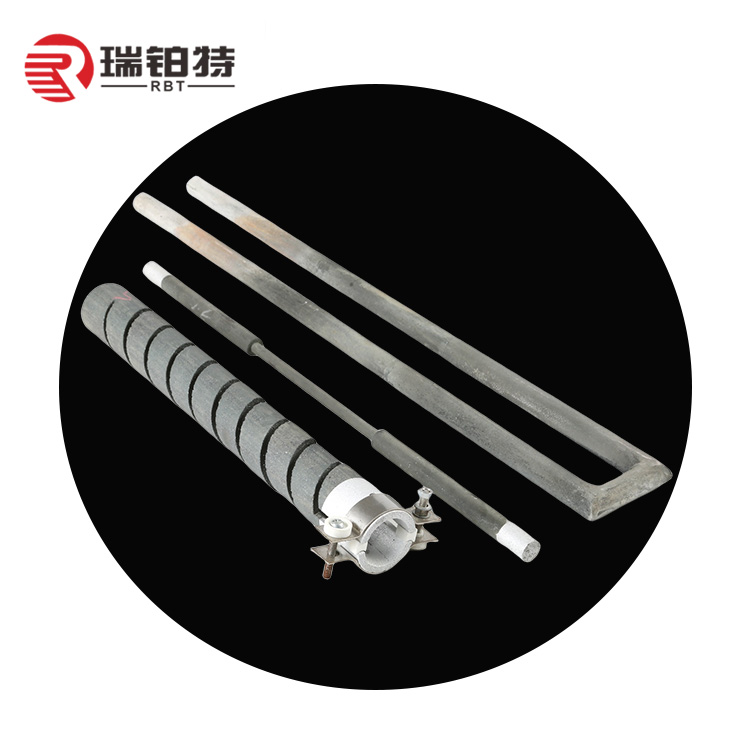

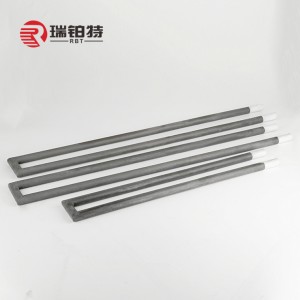

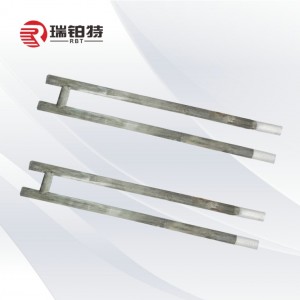

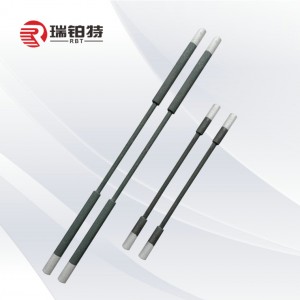

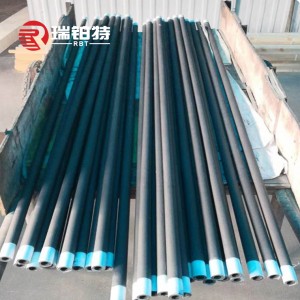

I-Silicon Carbide Rod Series

incazelo

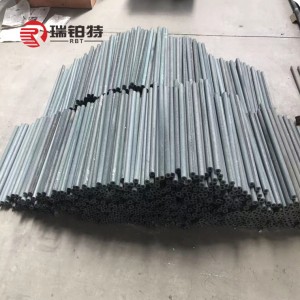

Izinti ze-silicon carbide ziyizinto zokushisa zikagesi ezimise okwenduku futhi ziyi-tubular non-metallic high-temperature eyenziwe nge-high-purity green hexagonal silicon carbide njengento eluhlaza eyinhloko, ecutshungulwa yaba izikhala ngokwesilinganiso esithile sempahla, futhi yashiswa ku-2200 ° C ukuze high-temperature siliconization, recrystallization kanye sintering.Izinga lokushisa elijwayelekile lokusebenzisa endaweni ene-oxidizing lingafinyelela ku-1450°C, futhi ukusetshenziswa okuqhubekayo kungafinyelela amahora angu-2000.

Izici

Izinduku ze-silicon carbide zinezinga lokushisa eliphezulu lesevisi, ukumelana nokushisa okuphezulu, ukumelana ne-oxidation, ukumelana nokugqwala, ukukhuphuka kwezinga lokushisa okusheshayo, impilo ende, ukuwohloka okuncane kokushisa okuphezulu, ukufakwa nokugcinwa okulula, njll, futhi kube nokusimama okuhle kwamakhemikhali.

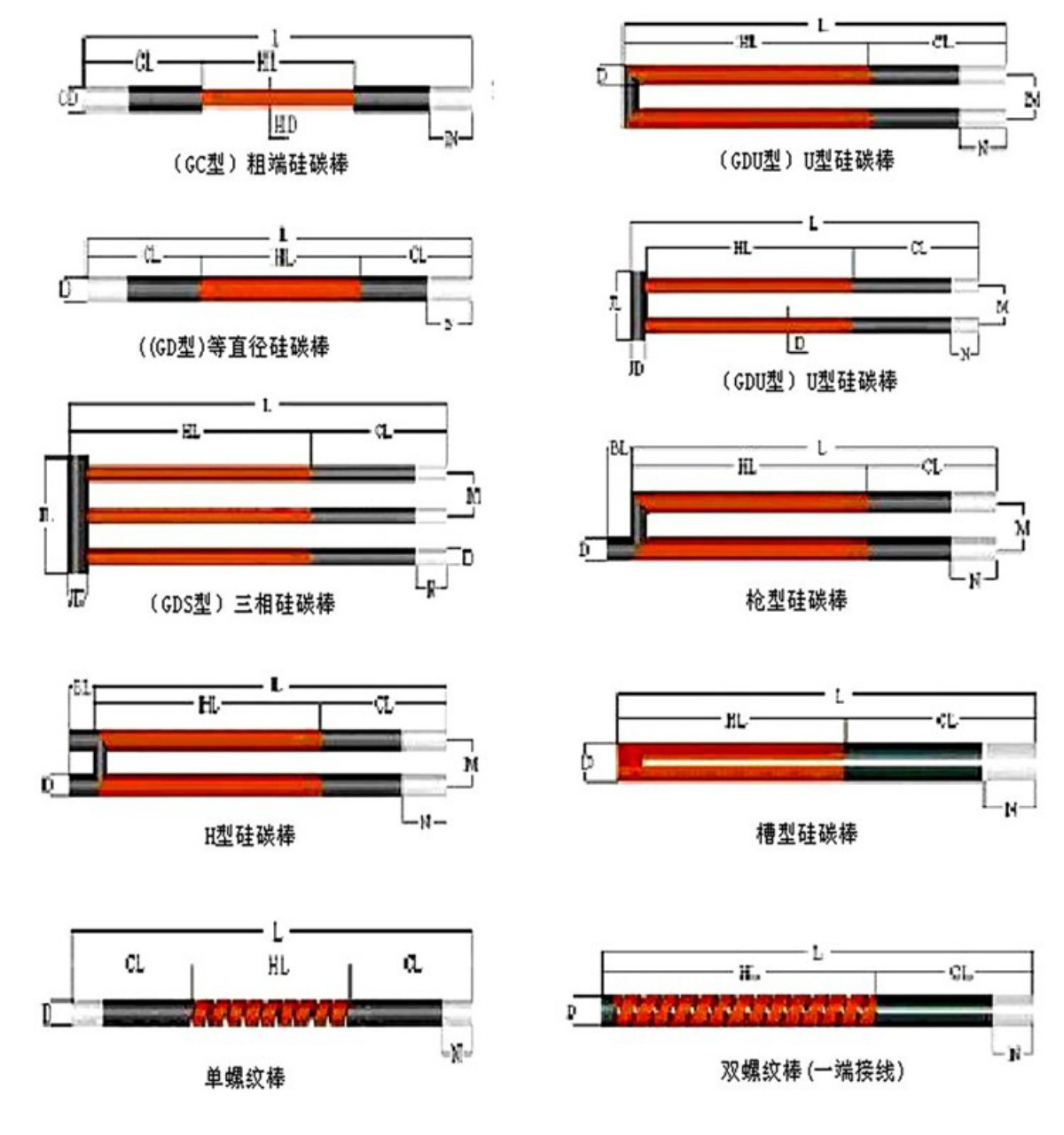

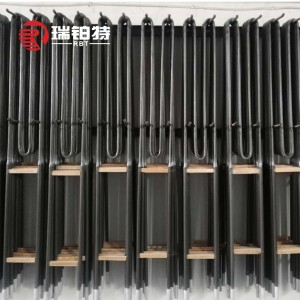

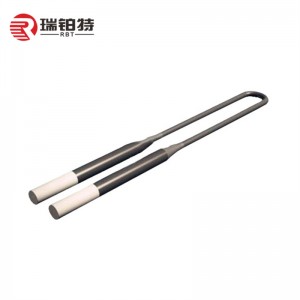

Amamodeli kanye Nemininingwane

Amamodeli we-silicon carbide rod abhekisela ezindongeni ze-3-segment, izinduku ze-5-segment, izinduku ezimise u-U, izinduku ezimise okwe-H, nezinduku ezimise okwesibhamu.Kalula nje, izinduku ze-5-segment kufanele zisetshenziselwe izikhathi ezidinga i-homogenization ephezulu, ngaphandle kwalokho kufanele kusetshenziswe izinduku ze-3-segment;Izinti ezimise okwe-H noma izinti ezimise u-U kufanele zisetshenziswe lapho kudingeka izintambo ezinomkhawulo owodwa;izinduku ezimise okwesibhamu kufanele zisetshenziselwe izitsha zokudla.Ukucaciswa kwezinti ze-silicon carbide kubhekisela kububanzi, ubude besici sokushisa, ubude bokuphela okubandayo, ubude bebhuloho, kanye nebanga eliphakathi.Ukuze uthole izinduku eziqondile (induku ye-3-section kanye ne-5-section rod), ubude bokuphela okubandayo buxhomeke ebukhulu bodonga lwesithando somlilo;ubude besici sokushisisa kufanele buhambisane nobubanzi bethangi eliwuketshezi lokuphakelayo, ngokuvamile kungabi ngaphansi kobubanzi bethangi eliwuketshezi lokuphakelayo.

Isicelo

Ukumatanisa nohlelo lokulawula i-elekthronikhi oluzenzakalelayo, lungathola izinga lokushisa elinembile njalo, futhi lungalungisa ngokuzenzakalelayo izinga lokushisa ngokwejika ngokuvumelana nezidingo zenqubo yokukhiqiza.Kuyinto elula, ephephile futhi enokwethenjelwa ukusebenzisa izinduku ze-silicon carbide ukushisa.Isetshenziswe kabanzi emikhakheni yokushisa ephezulu efana ne-electronics, izinto kazibuthe, i-powder metallurgy, izitsha zobumba, ingilazi, ama-semiconductors, ukuhlaziya nokuhlola, kanye nocwaningo lwesayensi.Izakhi zokushisa zikagesi zezinhlobo ezahlukene zemishini yokushisa.