I-Green Silicon Carbide

Ulwazi Lomkhiqizo

Isihlabathi se-silicon carbide esiluhlazaiyisithambisi esenziwe ngumuntu esinefomula yamakhemikhali ye-SiC. Yenziwe kakhulu ngesihlabathi se-quartz, i-petroleum coke (noma i-coke yamalahle) kanye nothuli lwe-sawdust ngokusebenzisa ukuncibilikisa okushisa okuphezulu esithandweni sokumelana. Isihlabathi se-silicon carbide esiluhlaza sinombala oluhlaza okotshanifuthi inezici eziningi ezibalulekile kanye nezinhlelo zokusebenza.

Ukusebenza kokucubungula

Ukusebenza kahle kokugaya okuphezulu:Ukuma kwezinhlayiya kanye nobunzima kwenza kube nokusebenza kahle kokugaya okuhle kakhulu, okungasusa ngokushesha ukungcola kanye nongqimba lwe-oxide ebusweni bento yokusebenza.

Impahla enhle yokuzilolonga:Usayizi kanye nesimo sezinhlayiya kuyalingana futhi kunomphetho we-blade, okuqinisekisa ukuthi iyakwazi ukuzilola ngokwayo njengento yokusika i-blade futhi kuqinisekisa ukuncishiswa kwezinto ezisikiwe.

Ukuzivumelanisa nezimo okuhle:Ingaguqulwa kahle ukuze ihambisane nezinhlobo ezahlukene zoketshezi lokusika ukuze kuthuthukiswe ukusebenza kahle kanye nekhwalithi yokucubungula.

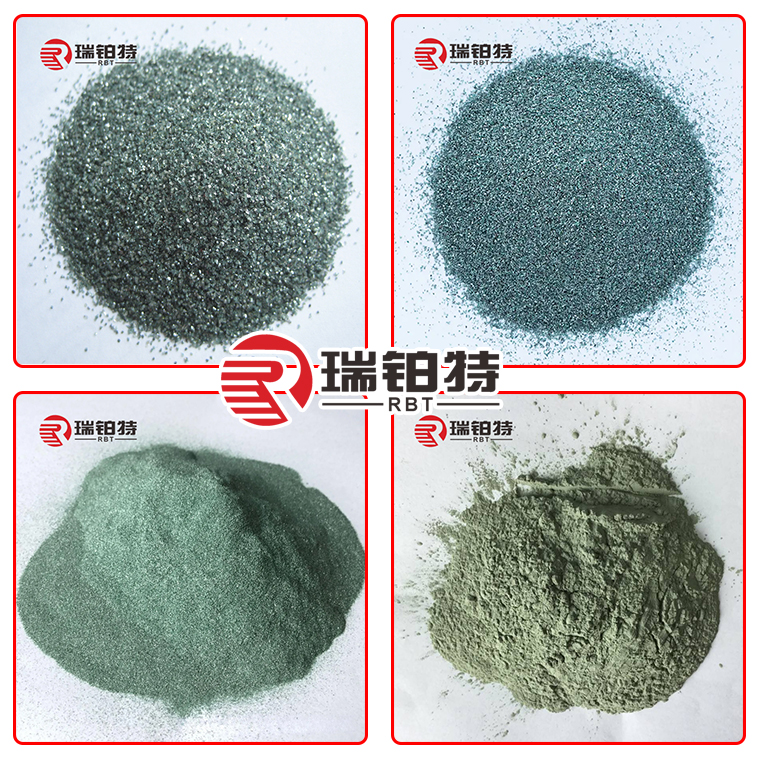

Izakhiwo Zomzimba

| Umbala | Okuluhlaza okotshani |

| Ifomu lekristalu | I-Polygon |

| Ukuqina kwe-Mohs | 9.2-9.6 |

| Ubulukhuni Obuncane | 2840~3320kg/mm² |

| Indawo Yokuncibilika | 1723 |

| Izinga Lokushisa Eliphezulu Lokusebenza | 1600 |

| Ubuningi Bangempela | 3.21g/cm³ |

| Ubuningi obukhulu | 2.30g/cm³ |

Imininingwane Izithombe

Ishadi Lokuqhathanisa Usayizi Wegrit

| Inombolo ye-Grit. | I-China GB2477-83 | I-Japan JISR 6001-87 | I-USA ANSI(76) | 欧洲磨料 FEPA(84) | 国际ISO(86) |

| 4 | 5600-4750 |

| 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 |

| 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 |

| 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - |

Inkomba Yomkhiqizo

| Usayizi Wegrit | Ukwakheka Kwamakhemikhali% (Ngesisindo) | ||

| I-SiC | F·C | I-Fe2O3 | |

| 12#-90# | ≥98.50 | ≤0.20 | ≤0.60 |

| 100#-180# | ≥98.00 | ≤0.30 | ≤0.80 |

| 220#-240# | ≥97.00 | ≤0.30 | ≤1.20 |

| I-W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| I-W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Isicelo

1. Okuhlabayo:I-carbon silicon carbide eluhlaza isetshenziswa kabanzi njengento yokuhudula ezimbonini ezahlukahlukene, okuhlanganisa izimoto, izindiza, ukusebenza ngensimbi, kanye nobucwebe. Isetshenziselwa ukugaya, ukusika, kanye nokupholisha izinsimbi eziqinile kanye nobumba.

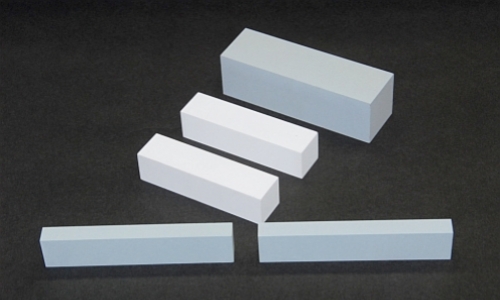

2. Okungaguquki:I-carbide ye-silicon eluhlaza isetshenziswa futhi njengento evimbela ukushisa ezindaweni zokushisa eziphakeme njengezitofu nama-oven ngenxa yokushisa kwayo okuphezulu kanye nokwanda okuphansi kokushisa.

3. Izinto zikagesi:I-carbonide eluhlaza isetshenziswa njengezinto ezisetshenziswayo zamadivayisi kagesi afana nama-LED, amadivayisi kagesi, namadivayisi e-microwave ngenxa yokuqhuba kwayo ugesi okuhle kakhulu kanye nokuqina kokushisa.

4. Amandla elanga:I-silicon carbide eluhlaza isetshenziswa njengento yokwakha amaphaneli elanga ngenxa yokushisa kwayo okuphezulu kanye nokukhula okuphansi kokushisa, okusiza ekuqedeni ukushisa okukhiqizwa ngesikhathi sokusebenza kwamaphaneli elanga.

5. I-Metallurgy:I-silicon carbide eluhlaza isetshenziswa njenge-deoxidizing agent ekukhiqizweni kwensimbi nensimbi. Iyasiza ekususeni ukungcola ensimbini encibilikisiwe nasekuthuthukiseni ikhwalithi yomkhiqizo wokugcina.

6. Izinto zobumba:I-carbide ye-silicon eluhlaza isetshenziswa njengento eluhlaza yokukhiqiza izinto zobumba ezithuthukisiwe njengamathuluzi okusika, izingxenye ezingagugi, kanye nezingxenye zokushisa okuphezulu ngenxa yobulukhuni bayo obuphezulu, amandla aphezulu, kanye nokuqina kokushisa okuhle kakhulu.

Iphakheji kanye ne-Warehouse

| Iphakheji | Isikhwama esingu-25KG | Isikhwama esingu-1000KG |

| Ubuningi | Amathani angu-24-25 | Amathani angu-24 |

Iphrofayela Yenkampani

I-Shandong Robert New Material Co., Ltd.itholakala eDolobheni laseZibo, eSifundazweni saseShandong, eShayina, okuyisisekelo sokukhiqiza izinto ezingaphili. Siyibhizinisi lesimanje elihlanganisa ucwaningo nentuthuko, ukukhiqiza, ukuthengisa, ukuklama nokwakha ihhavini, ubuchwepheshe, kanye nezinto ezingaphili kwamanye amazwe. Sinemishini ephelele, ubuchwepheshe obuthuthukisiwe, amandla aqinile obuchwepheshe, ikhwalithi yomkhiqizo enhle kakhulu, kanye nedumela elihle. Ifektri yethu ihlanganisa amahektha angaphezu kwama-200 kanti umkhiqizo waminyaka yonke wezinto ezingaphili ezimile ungaba amathani angama-30000 kanti izinto ezingaphili ezimile zingamathani ayi-12000.

Imikhiqizo yethu eyinhloko yezinto eziphikisayo ifaka:izinto zokuphikisa ze-alkaline; izinto zokuphikisa ze-aluminium silicon; izinto zokuphikisa ezingabunjwanga; izinto zokuphikisa ze-thermal insulation; izinto ezikhethekile zokuphikisa; izinto zokuphikisa ezisebenzayo zezinhlelo zokuphonsa eziqhubekayo.

imibuzo ejwayelekile ukubuzwa

Udinga usizo? Qiniseka ukuthi uvakashela izinkundla zethu zokusekela ukuze uthole izimpendulo zemibuzo yakho!

Singumkhiqizi wangempela, imboni yethu igxile ekukhiqizeni izinto eziphikisayo iminyaka engaphezu kwengu-30. Sithembisa ukukunikeza intengo engcono kakhulu, insizakalo engcono kakhulu yangaphambi kokuthengisa kanye neyangemva kokuthengisa.

Kuyo yonke inqubo yokukhiqiza, i-RBT inohlelo oluphelele lwe-QC lokwakheka kwamakhemikhali kanye nezakhiwo zomzimba. Futhi sizohlola izimpahla, futhi isitifiketi sekhwalithi sizothunyelwa nezimpahla. Uma unezidingo ezikhethekile, sizozama konke okusemandleni ethu ukuze sizilungiselele.

Kuye ngobuningi, isikhathi sethu sokulethwa sihlukile. Kodwa sithembisa ukuthumela ngokushesha ngangokunokwenzeka ngekhwalithi eqinisekisiwe.

Vele, sinikeza amasampula amahhala.

Yebo, vele, wamukelekile ukuvakashela inkampani ye-RBT kanye nemikhiqizo yethu.

Akukho mkhawulo, singakunikeza isiphakamiso nesixazululo esingcono kakhulu ngokuya ngesimo sakho.

Sesineminyaka engaphezu kwengu-30 senza izinto eziphikisayo, sinokusekelwa okuqinile kwezobuchwepheshe kanye nokuhlangenwe nakho okucebile, singasiza amakhasimende ukuklama ama-kiln ahlukene futhi anikeze isevisi eyodwa.