Uma sithatha ingilazi entantayo njengesibonelo, imishini emithathu emikhulu yokushisa ekukhiqizweni kwengilazi ihlanganisa isithando sokuncibilikisa ingilazi entantayo, isitsha sokugeza ingilazi entantayo kanye nesithando sokuncibilikisa ingilazi. Enqubweni yokukhiqizwa kwengilazi, isithando sokuncibilikisa ingilazi sinesibopho sokuncibilikisa izinto ze-batch zibe uketshezi lwengilazi nokucacisa, ukuzihlanganisa nokuzipholisa kuze kufike ekushiseni okudingekayo ukuze kufakwe ubumba. Isitsha sokugeza ingilazi siyimishini eyinhloko yokubumba ingilazi. Uketshezi lwengilazi olunokushisa okungu-1050 ~ 1100℃ lugeleza lusuka emgudwini wokugeleza luye ebusweni boketshezi lwethini ebhavini lethini. Uketshezi lwengilazi luyacwebezela futhi lupholishwe ebusweni bebhavini lethini, futhi lulawulwa ngokudonsa ngomshini, onogada baseceleni kanye nemishini yokudweba eceleni ukuze kwakheke iribhoni yengilazi enobubanzi nobukhulu obudingekayo. Futhi lushiya ibhavini lethini lapho luphola kancane kancane lufike ku-600℃ ngesikhathi senqubo yokuya phambili. Umsebenzi wesithando sokuncibilikisa ingilazi ukususa ukucindezeleka okusele kanye nokungalingani kokukhanya kwengilazi entantayo, kanye nokuqinisa isakhiwo sangaphakathi sengilazi. Iribhoni yengilazi eqhubekayo enokushisa okungu-600℃ okubangelwa yibhavini lethini ingena esithandweni sokuncibilikisa ingilazi ngetafula le-roller lokuguquka. Zonke lezi zixhobo ezintathu ezinkulu zokushisa zidinga izinto zokuphikisa. Ukuqinisekisa ukusebenza okuvamile nokuzinzile kwesithando sokuncibilikisa ingilazi, empeleni asihlukaniseki nokusekelwa kwezinto ezihlukahlukene zokuphikisa. Okulandelayo izinhlobo ezingu-9 zezinto zokuphikisa ezivame ukusetshenziswa ezithandweni zokuncibilikisa ingilazi kanye nezici zazo:

Izitini ze-silica zama-oven engilazi:

Izithako eziyinhloko: i-silicon dioxide (i-SiO2), okuqukethwe kuyadingeka kube ngaphezu kwama-94%. Izinga lokushisa lokusebenza: izinga lokushisa eliphezulu lokusebenza lingu-1600 ~ 1650℃. Izici: ukumelana okuhle nokuguguleka kwe-slag ene-asidi, kodwa ukumelana okuncane nokuguguleka kwezinto ezindizayo ze-alkaline. Isetshenziswa kakhulu ekwakheni ama-arches amakhulu, izindonga zesifuba kanye nezitofu ezincane.

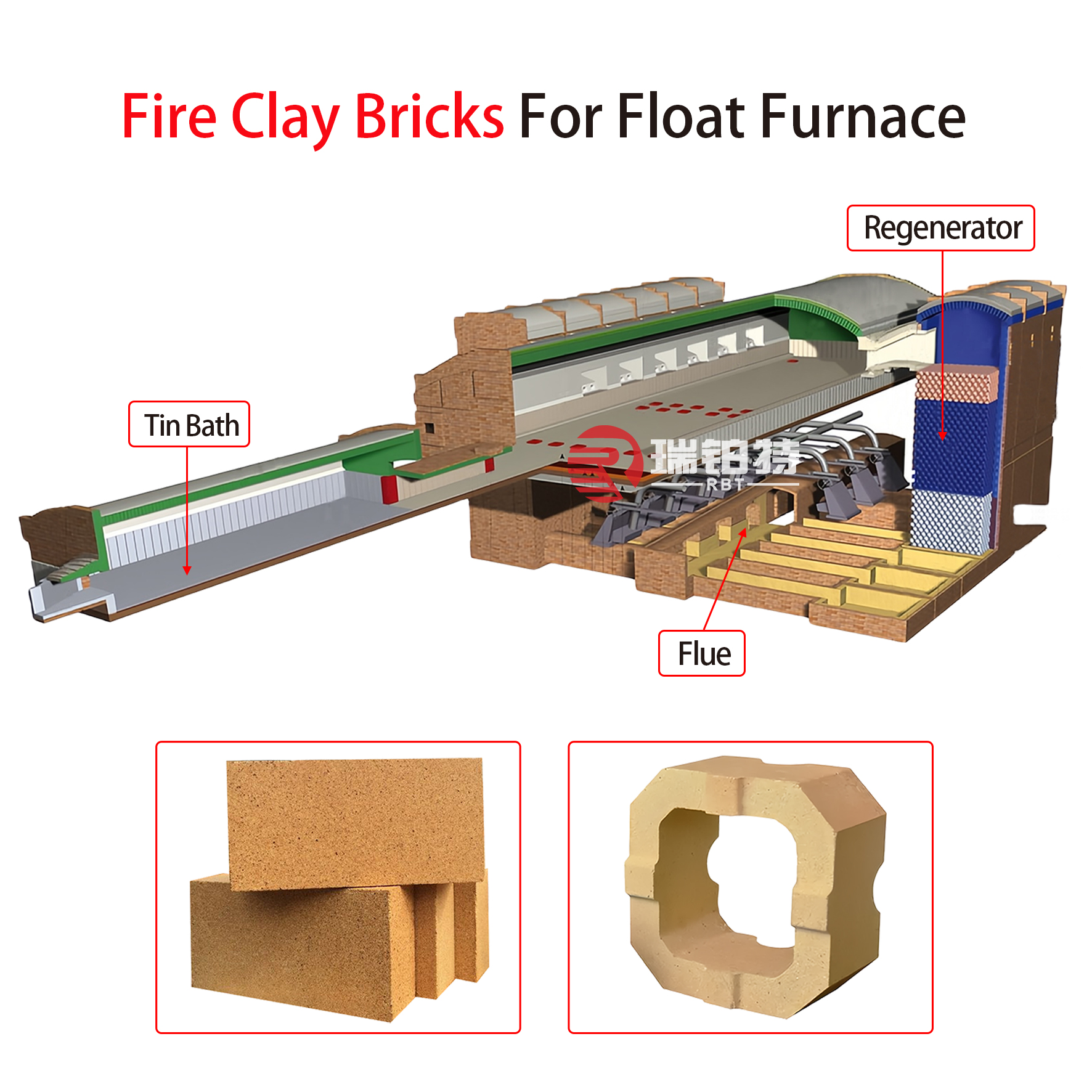

Izitini zobumba lomlilo zama-oven engilazi:

Izithako eziyinhloko: I-Al2O3 ne-SiO2, okuqukethwe yi-Al2O3 kuphakathi kuka-30% ~ 45%, i-SiO2 iphakathi kuka-51% ~ 66%. Izinga lokushisa lokusebenza: izinga lokushisa eliphezulu lokusebenza lingu-1350 ~ 1500℃. Izici: Kuyizinto ezibuthakathaka eziphikisana ne-acidic ezinokumelana okuhle, ukuzinza kokushisa kanye nokuqhuba ukushisa okuphansi. Isetshenziswa kakhulu ekubumbeni phansi kwechibi lesitofu, udonga lwechibi lwengxenye yokusebenza kanye nendlela yokudlula, udonga, i-arch, izitini eziphansi kanye ne-flue yegumbi lokugcina ukushisa.

Izitini ze-alumina eziphakeme zama-oven engilazi:

Izingxenye eziyinhloko: I-SiO2 ne-Al2O3, kodwa okuqukethwe kwe-Al2O3 kufanele kube ngaphezu kuka-46%. Izinga lokushisa lokusebenza: Izinga lokushisa eliphezulu lokusebenza lingu-1500 ~ 1650℃. Izici: Ukumelana okuhle nokugqwala, futhi kungamelana nokugqwala okuvela kokubili kuma-slag ane-acidic kanye ne-alkaline. Isetshenziswa kakhulu emakamelweni okugcina ukushisa, kanye nezesekeli eziphikisayo zamachibi okusebenza, iziteshi zezinto zokwakha kanye nezindawo zokondla.

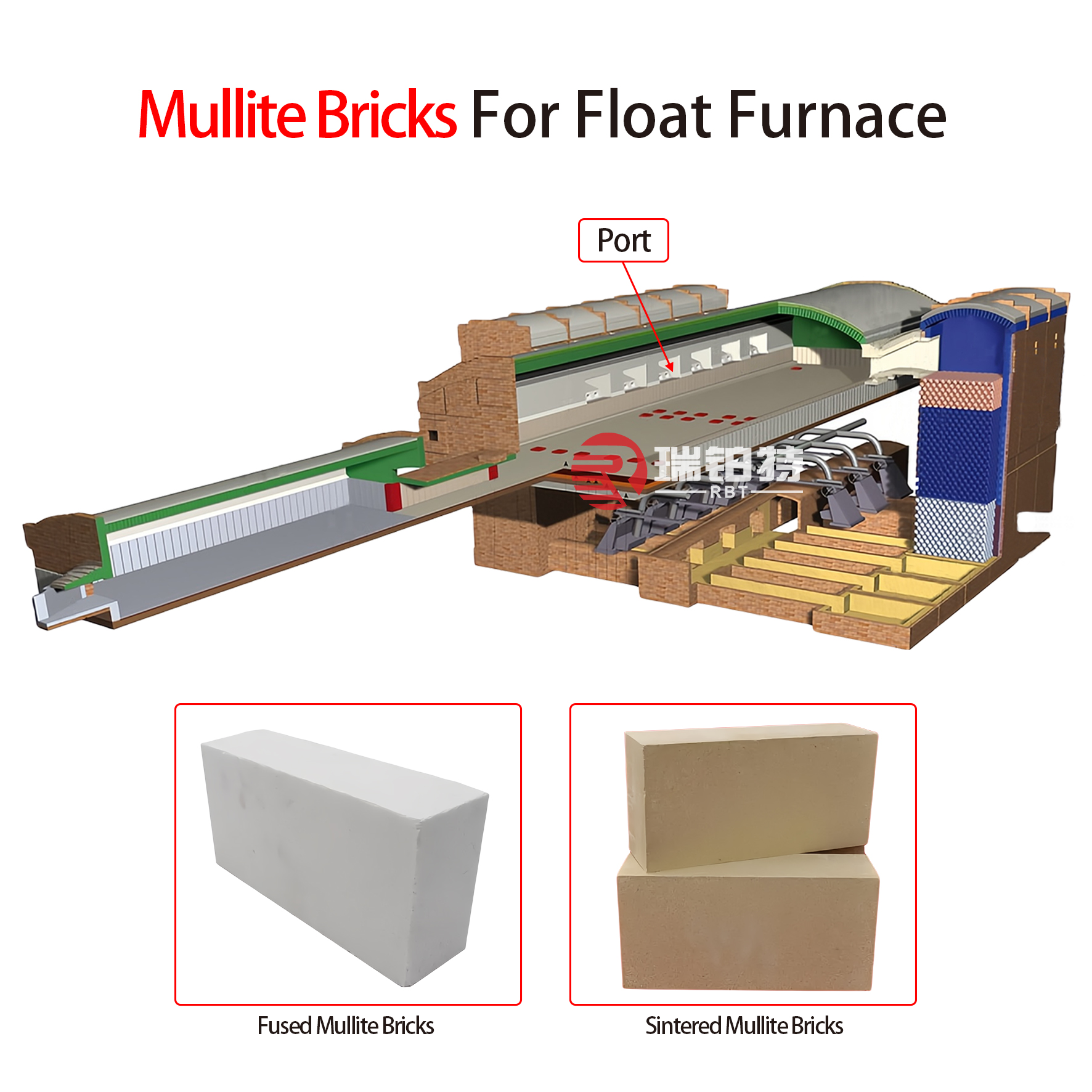

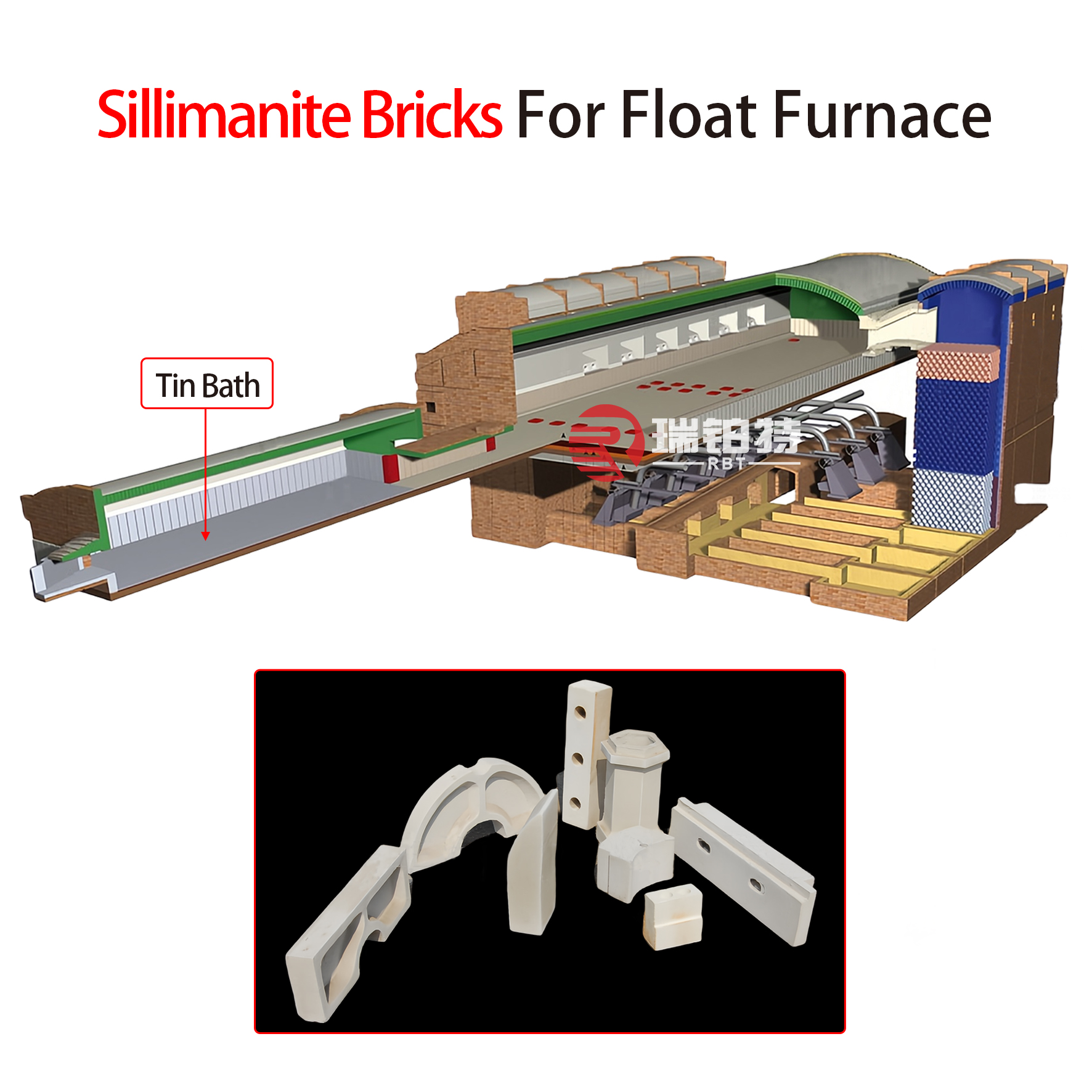

Izitini eziningi:

Ingxenye eyinhloko yezitini ze-mullite yi-Al2O3, futhi okuqukethwe kwayo kungama-75%. Ngenxa yokuthi ngokuyinhloko iyizikristalu ze-mullite, ibizwa ngokuthi izitini ze-mullite. Ubuningi 2.7-3 2g/cm3, i-porosity evulekile 1%-12%, kanti izinga lokushisa lokusebenza eliphakeme lingu-1500~1700℃. I-mullite e-sintered isetshenziswa kakhulu ekubumbeni izindonga zegumbi lokugcina ukushisa. I-mullite ehlanganisiwe isetshenziswa kakhulu ekubumbeni izindonga zechibi, imigodi yokubuka, izindonga zodonga, njll.

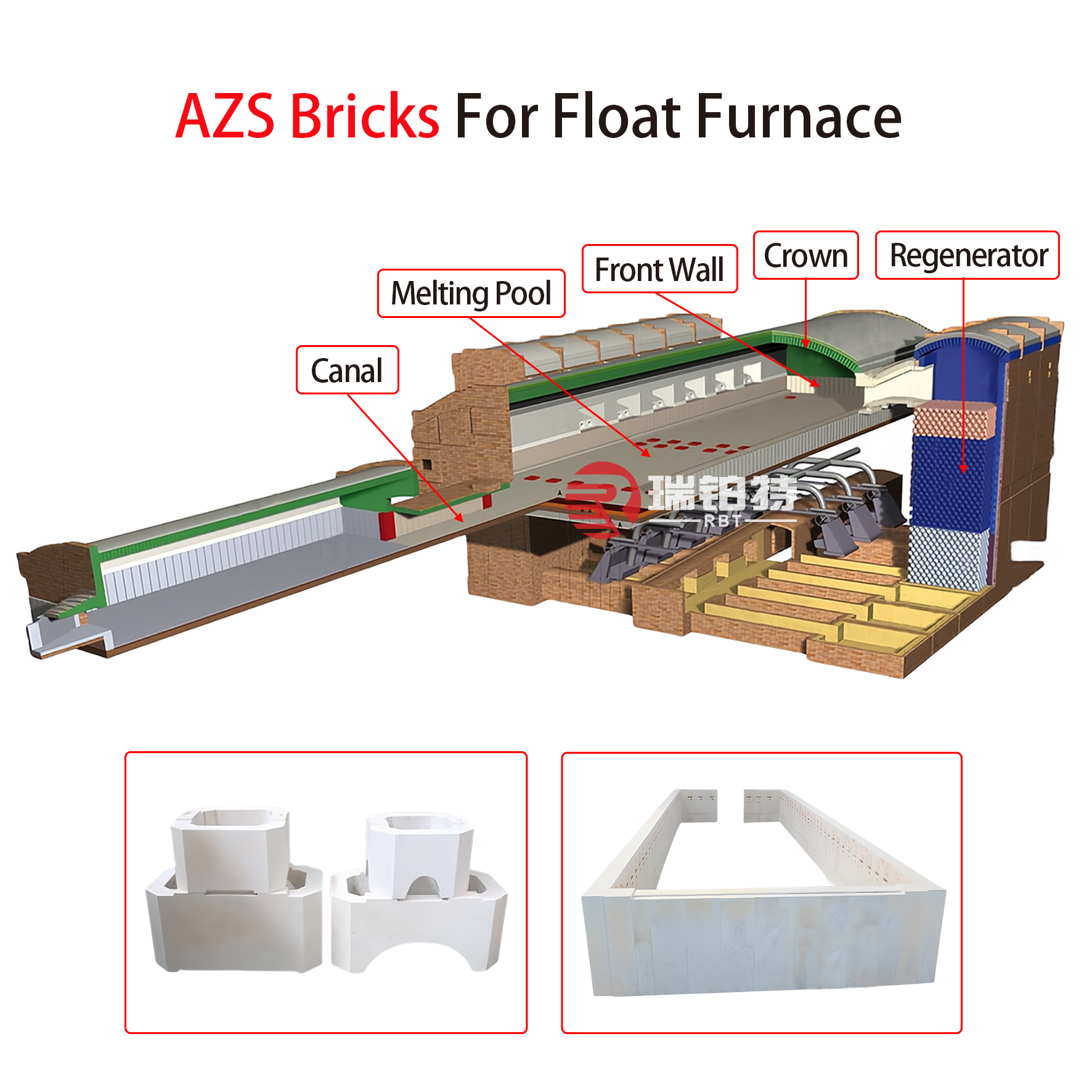

Izitini ze-zirconium corundum ezihlanganisiwe:

Izitini ze-zirconium corundum ezihlanganisiwe nazo zibizwa ngokuthi izitini zensimbi emhlophe. Ngokuvamile, izitini ze-zirconium corundum ezihlanganisiwe zihlukaniswe ngamabanga amathathu ngokuya ngokuqukethwe kwe-zirconium: 33%, 36%, kanye no-41%. Izitini ze-zirconium corundum ezisetshenziswa embonini yengilazi ziqukethe u-50% ~ 70% Al2O3 kanye no-20% ~ 40% ZrO2. Ubuningi bungu-3.4 ~ 4.0g/cm3, i-porosity ebonakalayo ingu-1% ~ 10%, kanti izinga lokushisa lokusebenza eliphakeme licishe libe ngu-1700℃. Izitini ze-zirconium corundum ezihlanganisiwe ezinokuqukethwe kwe-zirconium okungu-33% no-36% zisetshenziselwa ukwakha izindonga zamachibi e-oven, izindonga zesifuba sendawo yomlilo, imigodi emincane yokuqhuma kwesithando, imigodi emincane eyisicaba yesithando, inqwaba yezithando, imigqa yolimi, njll. Izitini ze-zirconium corundum ezihlanganisiwe ezinokuqukethwe kwe-zirconium okungu-41% zisetshenziselwa ukwakha amakhona odonga lwesithando, imigodi yokugeleza, nezinye izingxenye lapho uketshezi lwengilazi luguguleka futhi lugqwala izinto eziphikisayo kakhulu. Le nto iyinto esetshenziswa kakhulu embonini yengilazi ehlanganisiwe.

Izitini ze-alumina ezihlanganisiwe:

Ibhekisela kakhulu ezitini ezixubile ze-α, i-β corundum, kanye ne-β corundum refractory ezixubile, ezakhiwe kakhulu yi-92% ~ 94% Al2O3 corundum crystal phase, ubuningi obungu-2.9 ~ 3.05g/cm3, i-porosity ebonakalayo engu-1% ~ 10%, kanye nokushisa okuphezulu kokusebenza okungu-1700℃. I-alumina exubile inokumelana okuhle kakhulu nokugeleza kwengilazi futhi cishe ayinakho ukungcola koketshezi lwengilazi. Isetshenziswa kabanzi odongeni lwechibi lengxenye yokusebenza, phansi kwechibi, isiteshi sokugeleza, odongeni lwechibi lengxenye yokusebenza, phansi kwechibi lengxenye yezinto kanye nezinye izingxenye zesithando sokuncibilikisa ingilazi ezithinta uketshezi lwengilazi futhi ezingadingi ukungcola okuphikisayo.

Izitini ze-quartz:

Ingxenye eyinhloko yi-SiO2, equkethe okungaphezu kuka-99%, enobuningi obungu-1.9~2g/cm3, ukuphikiswa okungu-1650℃, izinga lokushisa lokusebenza elingaba ngu-1600℃, kanye nokumelana nokuguguleka kwe-asidi. Isetshenziselwa ukwakha udonga lwechibi ngengilazi ye-boron ene-acidic, izitini zemigodi ye-thermocouple yesikhala somlilo, njll.

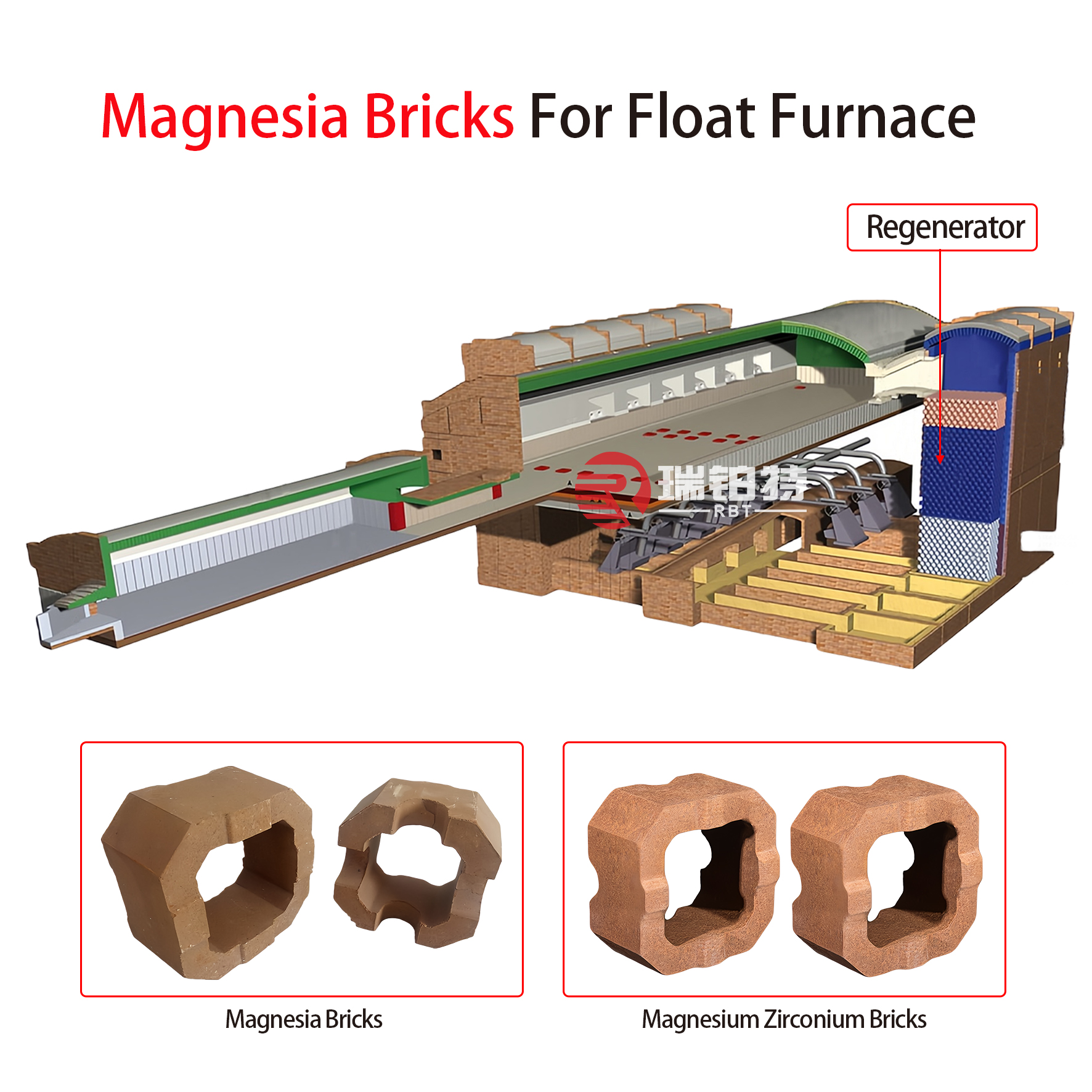

Izinto eziphikisayo ze-alkaline:

Izinto eziphikisayo ze-alkaline zibhekisela kakhulu ezitini ze-magnesia, izitini ze-alumina-magnesia, izitini ze-magnesia-chrome, kanye nezitini ze-forsterite. Ukusebenza kwayo ukumelana nokuguguleka kwezinto ze-alkaline, futhi ukumelana kwayo kungu-1900 ~ 2000℃. Isetshenziswa kabanzi odongeni olungaphezulu lwe-regenerator yesithando sokuncibilikisa ingilazi, i-arch ye-regenerator, umzimba wegridi, kanye nesakhiwo sengxenye yesithando esincane.

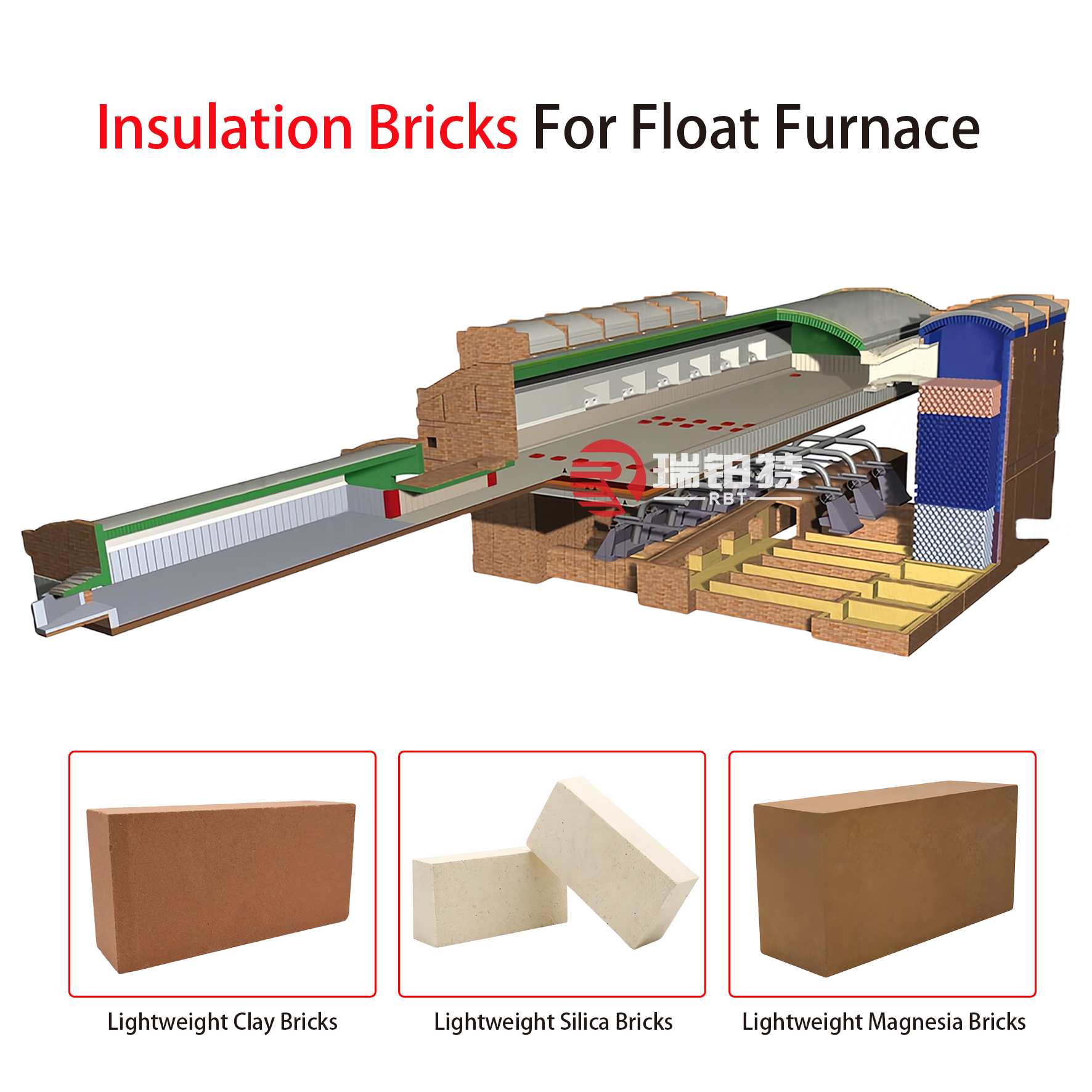

Izitini zokuvala umoya zezitofu zeglasi:

Indawo yokushabalalisa ukushisa kwesithando sokuncibilikisa ingilazi inkulu futhi ukusebenza kahle kokushisa kuphansi. Ukuze kongiwe amandla futhi kuncishiswe ukusetshenziswa, kudingeka inani elikhulu lezinto zokushisa ukuze kushabalaliswe ngokuphelele. Ikakhulukazi, udonga lwechibi, phansi kwechibi, i-arch, nodonga ku-regenerator, ingxenye yokuncibilikisa, ingxenye esebenzayo, njll. kufanele kushabalaliswe ukuze kuncishiswe ukushabalalisa ukushisa. Izimbobo zesitini sokushisa zikhulu kakhulu, isisindo silula kakhulu, futhi ubuningi abudluli ku-1.3g/cm3. Njengoba ukusebenza kokudlulisa ukushisa komoya kuphansi kakhulu, isitini sokushisa esinezimbobo ezinkulu sinomphumela wokushisa. I-coefficient yayo yokuqhuba ukushisa iphansi ngokuphindwe kabili kuya kathathu kunezinto ezijwayelekile zokuphikisa, ngakho-ke uma izimbobo zikhulu, umphumela wokushisa ungcono. Kunezinhlobo eziningi ezahlukene zezitini zokushisa, kufaka phakathi izitini zokushisa zobumba, izitini zokushisa ze-silica, izitini zokushisa ze-alumina ephezulu nokunye.

Isikhathi sokuthunyelwe: Ephreli-25-2025