Isingeniso

Ezimbonini ezishisa kakhulu—kusukela ekwenzeni insimbi kuya ekukhiqizweni kwengilazi—izinto ezikhipha umoya ziwumgogodla wokusebenza okuphephile nokusebenza kahle. Phakathi kwalezi,izitini ze-mulliteZivelele ngokuqina kwazo okumangalisayo kokushisa, ukumelana nokugqwala, kanye namandla omshini. Ukuqonda ukuhlukaniswa kwazo kanye nezinhlelo zokusebenza kubalulekile emabhizinisini afuna ukwenza ngcono isikhathi sokuphila kwemishini nokunciphisa izindleko zokusebenza. Lesi sihloko sichaza izinhlobo ezibalulekile zezitini ze-mullite kanye nokusetshenziswa kwazo emhlabeni wangempela, okukusiza ukuthi wenze izinqumo ezinolwazi ngezidingo zakho zezimboni.

Ukuhlukaniswa kwezitini ze-Mullite

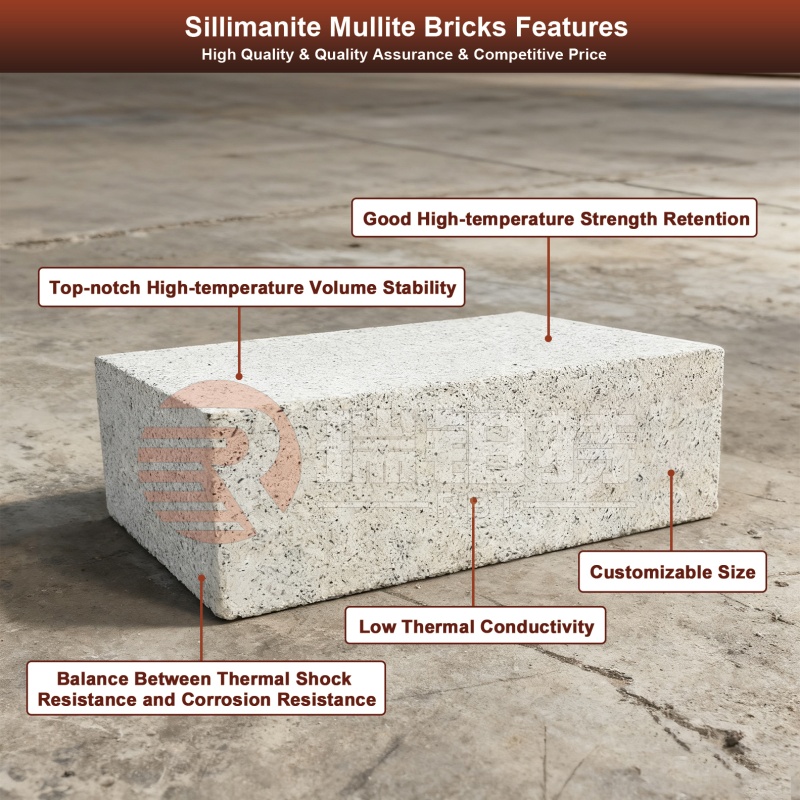

Izitini ze-Mullite zihlukaniswa ngezigaba ngokusekelwe ezinqubweni zokukhiqiza kanye nezingxenye ezengeziwe, ngayinye ilungiselelwe izidingo ezithile zezimboni.

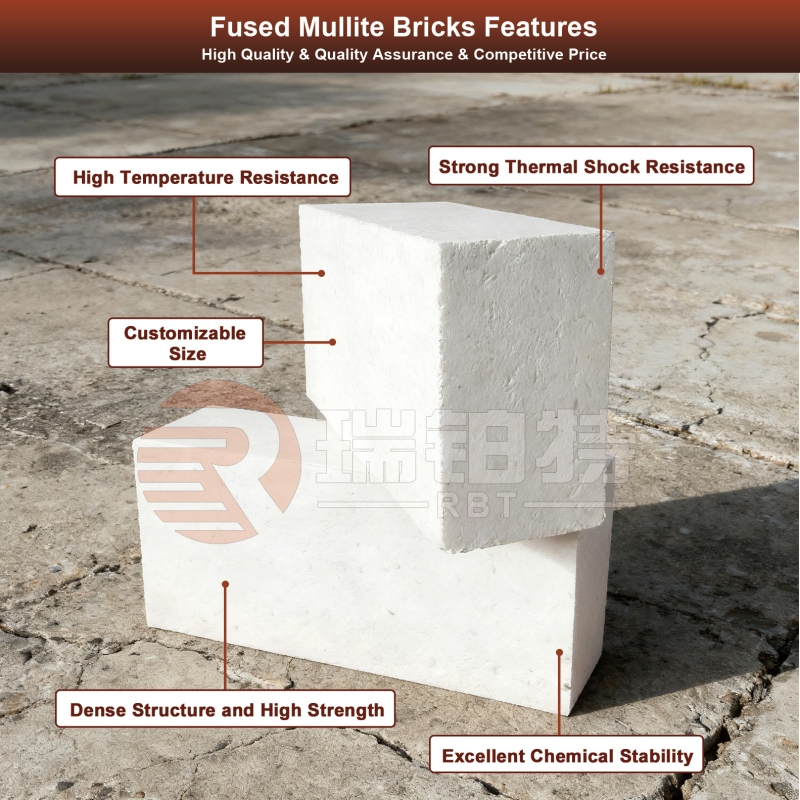

1. Izitini Ezihlanganisiwe Ze-Mullite

Kwenziwe ngokuxuba i-alumina ne-silica ehlanzekile kakhulu, kulolongwe ingxube, futhi kuyishise emazingeni okushisa angaphezu kuka-1600°C, izitini ze-mullite ezisikiwe zinesakhiwo esiqinile kanye ne-porosity ephansi (ngokuvamile ngaphansi kuka-15%). Lezi zici zinikeza ukumelana okuhle kakhulu nokuguguleka kanye nokumelana nokushaqeka kokushisa—okufanelekile ezindaweni ezinokuguquguquka okuvamile kokushisa. Ukusetshenziswa okuvamile kufaka phakathi ama-linings ama-ceramic kilns, ama-blast furnace hot blast stoves, kanye namakamelo okushisa e-boiler.

2. Izitini ze-Mullite ezihlanganisiwe

Njengoba zikhiqizwa ngokuncibilikisa izinto zokusetshenziswa (i-alumina, i-silica) esithandweni sikagesi se-arc (ngaphezu kuka-2000°C) bese kuphonswa ingxube encibilikisiwe ezikhumbeni, izitini ze-mullite ezihlanganisiwe zinezinga eliphansi kakhulu lokungcola kanye nobumsulwa obuphezulu bekristalu. Ukumelana kwazo okuphezulu nokuguguleka kwamakhemikhali (isb., kusuka engilazini encibilikisiwe noma ama-slag) kuzenza zibe yisinqumo esihle kakhulu sama-regenerator esithando seglasi, amabhati engilazi entantayo, kanye neminye imishini evezwe emithonjeni encibilikisiwe enamandla.

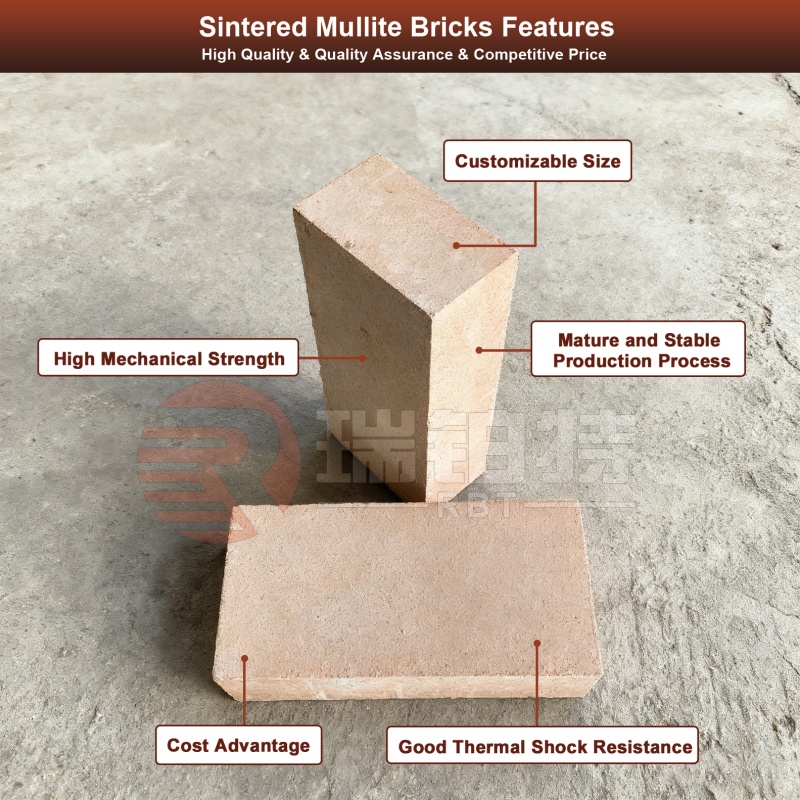

3. Izitini Ezilula Ezine-Mullite

Njengoba kudalwe ngokungeza izinto ezenza imigodi (isb., uthuli lwesawdust, i-graphite) ngesikhathi sokukhiqizwa, izitini ze-mullite ezilula zine-porosity engu-40-60% kanye nobuningi obuphansi kakhulu kunezinhlobo ezisikiwe noma ezihlanganisiwe. Inzuzo yazo eyinhloko ukuhanjiswa kokushisa okuphansi (0.4-1.2 W/(m·K)), okunciphisa ukulahleka kokushisa. Zisetshenziswa kabanzi njengezingqimba zokuvikela kuma-oven, kuma-oven, nasemishinini yokwelapha ukushisa, lapho isisindo kanye nokusebenza kahle kwamandla kuyizinto eziza kuqala.

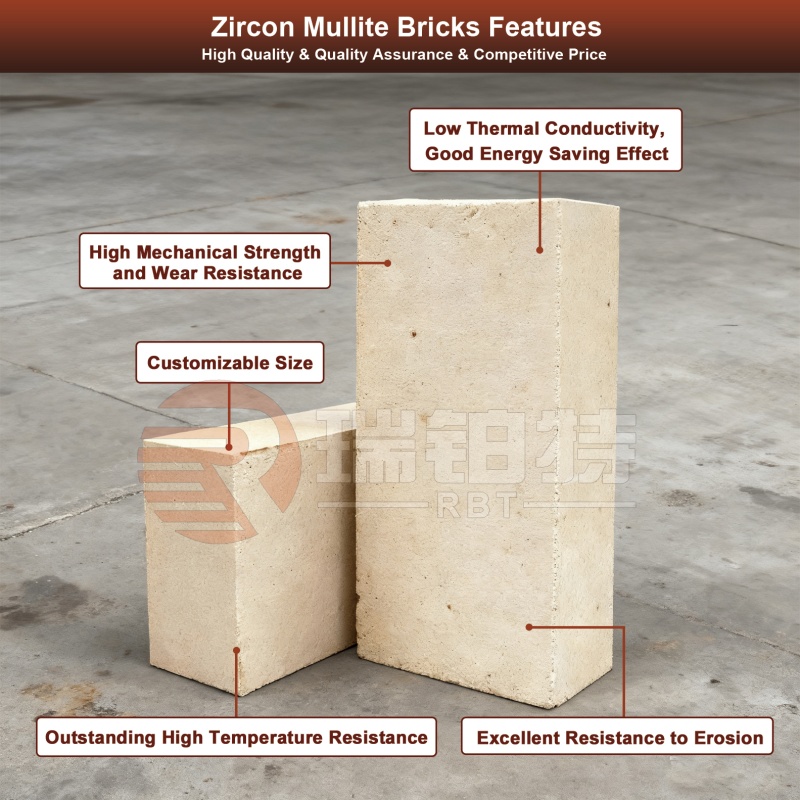

4. Izitini zeZircon Mullite

Ngokufaka i-zircon (ZrSiO₄) engxubeni yezinto zokusetshenziswa, izitini ze-zircon mullite zithola ukusebenza okuthuthukisiwe kwezinga lokushisa eliphezulu—zingamelana namazinga okushisa afinyelela ku-1750°C futhi zimelane nokuguguleka okuvela kuma-slag ane-asidi. Lokhu kuzenza zifanelekele izindawo ezinzima njengezitofu zokuncibilikisa insimbi ezingenayo i-ferrous (isb., amaseli okunciphisa i-aluminium) kanye nezindawo zokushisa ze-simende.

Ukusetshenziswa Kwezitini Eziningi

Ukuguquguquka kwezitini eziningi kuzenza zibaluleke kakhulu ezimbonini eziningi ezishisa kakhulu.

1. Imboni Yensimbi

Ukukhiqizwa kwensimbi kuhilela amazinga okushisa aphezulu (kufika ku-1800°C) kanye nama-slag agqwalisayo. Izitini ze-mullite ezisikiwe zimboza izitofu ezishisayo, lapho ukumelana kwazo nokushisa kuvimbela ukuqhekeka ekushiseni/ekupholeni okusheshayo. Izinhlobo ezihlanganisiwe zivikela ama-ladle nama-tundishes, kunciphisa ukuguguleka kwama-slag futhi kwandise impilo yemishini ngo-20-30% uma kuqhathaniswa nezindlela zendabuko zokungaguquki.

2. Imboni Yesimende

Ama-oven ajikelezayo esimende asebenza ku-1450–1600°C, kanti ama-alkaline slag abangela ingozi enkulu yokuguguleka. Izitini ze-zircon mullite zigudla indawo evuthayo yesitofu, zimelana nokuhlaselwa yi-alkali futhi zigcina ubuqotho besakhiwo. Izitini ze-mullite ezilula nazo zisebenza njengezingqimba zokuvikela, zinciphisa ukusetshenziswa kwamandla ngo-10–15%.

3. Imboni Yengilazi

Ingilazi encibilikisiwe (1500–1600°C) igqwala kakhulu, okwenza izitini ze-mullite ezihlanganisiwe zibalulekile kuma-regenerator esithando seglasi kanye nezinhlaka zamathangi. Zivimbela ukungcoliswa kwengilazi futhi zandisa isikhathi sokusebenza kwesithando seglasi sibe yiminyaka engu-5-8, kusukela eminyakeni engu-3-5 ngezinye izinto.

4. Ezinye Izimboni

Ekuncibilikisweni kwensimbi okungeyona insimbi (i-aluminium, ithusi), izitini ze-zircon mullite ziyamelana nokuguguleka kwensimbi encibilikisiwe kanye ne-slag. Kumakhemikhali e-petrochemical, izitini ze-mullite ezisikiwe zivala izitofu eziqhekekayo ngenxa yokuqina kwazo kokushisa. Ku-ceramics, izitini ze-mullite ezilula zivikela ama-kiln, zinciphisa ukusetshenziswa kwamandla.

Isiphetho

Izinhlobo ezahlukene zezitini ze-mullite—ezifakwe i-sintered, ezihlanganisiwe, ezilula, kanye ne-zircon—zihlangabezana nezidingo ezihlukile zezimboni ezishisa kakhulu. Kusukela ekukhuliseni ukusebenza kahle kwesithando sensimbi kuya ekwandiseni impilo yesithando sengilazi, ziletha izinzuzo ezibonakalayo: isikhathi eside semishini, izindleko zamandla eziphansi, kanye nesikhathi esincishisiwe sokungasebenzi. Njengoba izimboni ziphishekela umkhiqizo ophezulu kanye nokusimama, izitini ze-mullite zizohlala ziyisixazululo esiyinhloko. Khetha uhlobo olufanele lwesicelo sakho, bese uvula amandla azo aphelele.

Isikhathi sokuthunyelwe: Okthoba-31-2025