Emisebenzini yezimboni lapho imishini ibhekene nokuguguleka okungapheli, ukugqwala, kanye nomthelela, ukuthola izixazululo zokuvikela ezithembekile kubalulekile ekunciphiseni isikhathi sokungasebenzi kanye nokwandisa umkhiqizo. Amathayili e-Alumina Ceramic Mosaic avela njengoshintsho olukhulu, ehlanganisa isayensi yezinto ezithuthukisiwe nomklamo we-modular ukuze alethe ukuqina okungenakuqhathaniswa kanye nokuguquguquka. Aklanyelwe izimo ezimbi kakhulu, lawa mathayili achaza kabusha ukuvikelwa kwemishini kuzo zonke izimboni ezibalulekile emhlabeni jikelele.

Ukunemba Okulinganiselwe: Amandla Omklamo KaMose

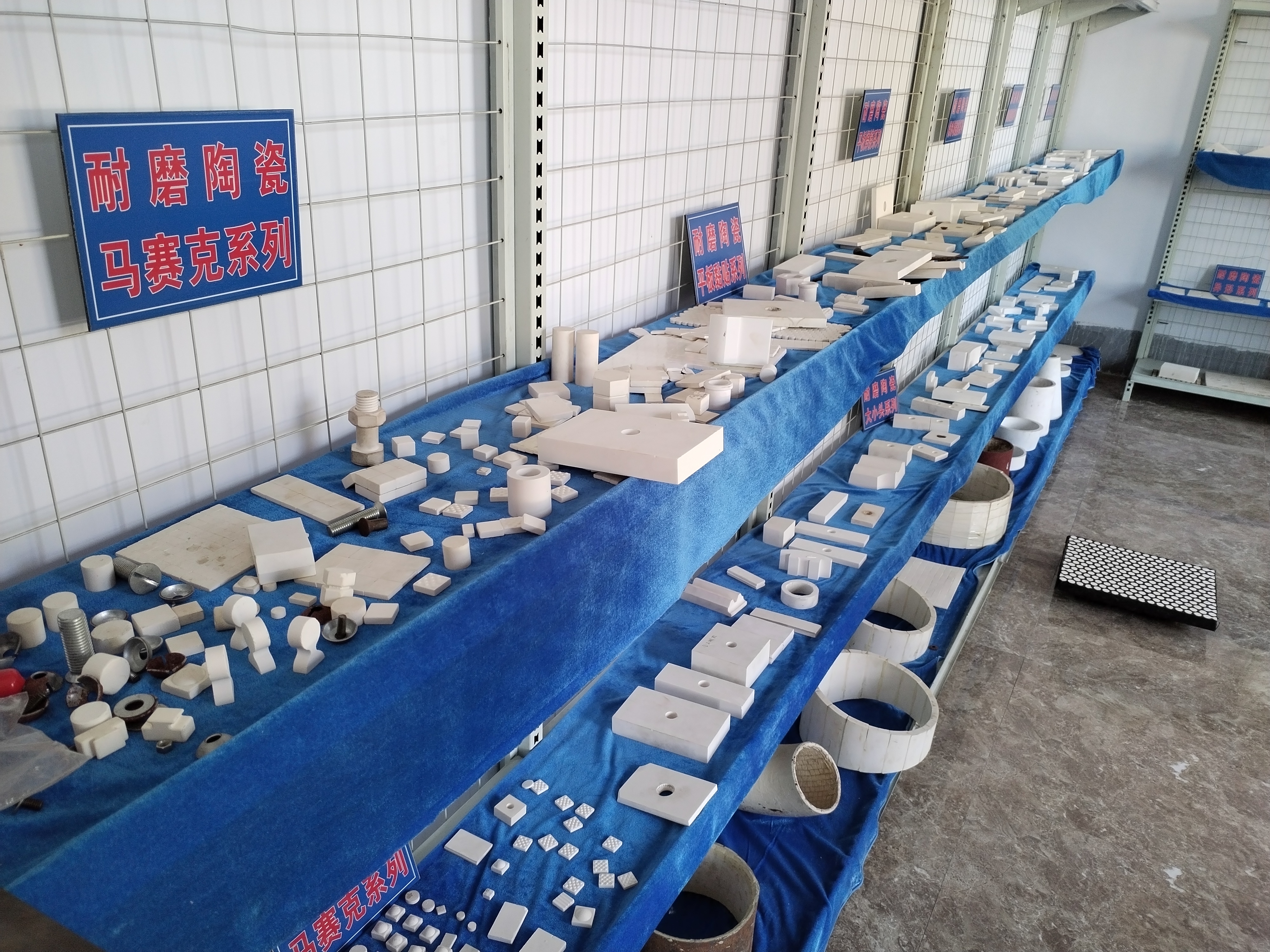

Enhliziyweni yamathayili e-alumina ceramic mosaic kukhona isakhiwo sawo esisha se-modular. Akhiwe njengamathayili amancane, aklanywe ngokunemba (ngokuvamile angu-10mm–50mm ngobukhulu), anikeza ukuguquguquka okungenakuqhathaniswa ekufakweni. Ngokungafani nama-liners amakhulu aqinile, lawa mathayili e-mosaic angenziwa ngokwezifiso ukuze afane nanoma yisiphi isimo semishini—kusukela kumapayipi agobile nama-hopper ayindilinga kuya kuma-chutes anomumo ongavamile kanye nezindonga zangaphakathi zokugaya. Ithayili ngalinye lenziwe ngokubekezelelana okuqinile, okuqinisekisa ukubopha okungenamthungo okudala ungqimba oluvikelayo oluqhubekayo, olungangeni.

Lokhu kulungiswa kwesakhiwo kwenza kube lula nokugcinwa: uma ithayela elilodwa lonakele (okuyinto engavamile), lingashintshwa ngalinye ngaphandle kokususa lonke uhlelo lwe-liner, kunciphisa isikhathi sokungasebenzi kanye nezindleko zokulungisa kakhulu. Kungakhathaliseki ukuthi kufakwa kabusha imishini ekhona noma kuhlanganiswa nemishini emisha, amathayela e-alumina ceramic mosaic avumelana nezidingo zakho ngokunemba okungenakuqhathaniswa.

Ukumelana Nokugqwala Okungenakuqhathaniswa

Amathayili e-mosaic e-Alumina ceramic akhiwe nge-alumina emsulwa kakhulu (90%–99% Al₂O₃), ewanika izakhiwo ezihlukile zemishini. Ngobunzima be-Mohs obungu-9—okwesibili emva kwedayimane—adlula izinto zendabuko njengensimbi, irabha, noma ama-polymer liners ekumelaneni nokuguguleka okuvela emadwaleni, amaminerali, nezinto ezihlanganisiwe. Emisebenzini yezimayini, isibonelo, amelana nokushaywa njalo kwe-ore kuma-crusher nama-conveyor, agcina ubuqotho bawo ngisho nangemva kweminyaka eminingi yokusetshenziswa kakhulu.

Ngaphandle kokumelana nokuguguleka, lawa mathayela asebenza kahle ezindaweni zamakhemikhali ezinzima. Awanawo amandla amaningi kuma-asidi, ama-alkali, kanye nezinyibilikisi, okwenza abe afanelekela izimboni zokucubungula amakhemikhali, lapho uketshezi olugqwalisayo kanye namagesi kuzolimaza khona izinto ezincane. Uma kuhlanganiswa nekhono lawo lokumelana namazinga okushisa afinyelela ku-1600°C, ayisinqumo esithembekile sezicelo zokushisa okuphezulu njengezitofu zensimbi kanye nama-oven esimende.

Yenzelwe Imikhakha Ebalulekile Yezimboni

Ukuguquguquka kwamathayili e-alumina ceramic mosaic kuwenza abe yinto ebalulekile kuzo zonke izimboni ezihlushwa ukuguguleka kwemishini. Nansi indlela athuthukisa ngayo inani emikhakheni ebalulekile:

Ukumba kanye Nezimbiwa:Vikela ama-crusher, ama-ball mills, futhi udlulise ama-chute kusuka ku-ore e-abrasive, unciphise imijikelezo yokushintsha imishini ngokuphindwe kathathu kuya kahlanu.

Ukukhiqizwa Kwesimende: Faka umugqa ezigayweni zezinto zokusetshenziswa, ezipholile ze-clinker, kanye nemigudu yokuqoqa uthuli ukuze umelane namandla okuguguleka kwezinhlayiya zesimende, uqinisekise ukukhiqizwa okungaphazamiseki.

Ukucubungula Amakhemikhali:Vikela izindonga ze-reactor, ama-agitator blades, namathangi okugcina izinto ezingcolisayo, uvimbele ukungcola futhi wandise impilo yempahla.

Ukukhiqizwa Kwamandla:Izinhlelo zokuhambisa amalahle ezivikelayo, amapayipi okuphatha umlotha, kanye nezingxenye zebhoyila ekukhucululweni komlotha ompukane, okunciphisa izindleko zokulungisa izitshalo zikagesi.

Ukuphathwa Kwemfucuza:Ama-liners okushisa imfucuza kanye nemishini yokuvuselela ukuze imelane nezinto ezikhuhlayo nezishisa kakhulu.

Kungakhathaliseki ukuthi isicelo sisebenza kanjani, lawa mathayela enzelwe ukuxazulula izinselele zakho zokuguguleka ezibaluleke kakhulu.

Ukutshalwa Kwezimali Okungabizi Kakhulu Ekusebenzeni Kahle Kwesikhathi Eside

Nakuba amathayili e-alumina ceramic mosaic emelela utshalomali oluphambili kusengaphambili, ukonga kwawo izindleko zomjikelezo wokuphila akunakuphikwa. Ngokunciphisa isikhathi sokungasebenzi kwemishini (okungabiza imisebenzi yezimboni izinkulungwane ngehora), ukunciphisa izingxenye ezithathelwa indawo, kanye nokwandisa isikhathi sokuphila kwemishini, aletha imbuyiselo esheshayo ekutshalweni kwezimali (i-ROI)—ngokuvamile zingakapheli izinyanga ezingu-6-12.

Uma kuqhathaniswa nama-liner ensimbi adinga ukushintshwa njalo, noma ama-liner enjoloba aphela ngokushesha emazingeni okushisa aphezulu, amathayili e-alumina mosaic anikeza ukusebenza "kokulingana nokukhohlwa". Izidingo zawo zokunakekelwa okuphansi kanye nokuphila isikhathi eside kwesevisi (iminyaka emi-5-10 ezinhlelweni eziningi) kuzenza zibe ukukhetha okuhlakaniphile kwamabhizinisi agxile ekusebenzeni okusimeme nokungabizi kakhulu.

Ukulungele Ukuguqula Ukuvikelwa Kwemishini Yakho?

Uma imisebenzi yakho ivinjelwa ukuguguleka kwemishini njalo, izindleko zokulungisa eziphezulu, noma isikhathi sokungasebenzi esingahleliwe, amathayili e-alumina ceramic mosaic ayisisombululo osidingayo. Ukwakheka kwawo kwe-modular, ukuqina kwemboni, kanye nokusebenza okuqondene nomkhakha kuwenza abe yindinganiso yegolide ekuvikeleni ukuguguleka.

Xhumana nethimba lethu namuhla ukuze uxoxe ngezidingo zakho zesicelo ezihlukile. Sizokunikeza imininingwane yethayela elenziwe ngokwezifiso, isiqondiso sokufakwa, kanye nokuhlaziywa kokusebenza kwamahhala ukukhombisa ukuthi ungonga malini. Vumela amathayela e-mosaic e-alumina ceramic aguqule imishini yakho isuke ekubeni yisibopho ibe yimpahla yesikhathi eside—ngoba emisebenzini yezimboni, ukuqina akuyona inketho—kuyisidingo.

Isikhathi sokuthunyelwe: Julayi-23-2025