Ukusetha i-Al2O3 engu-5% kuya ku-10% (ingxenye yesisindo) engxenyeni ye-matrix yezitini ze-carbon/graphite ze-blast furnace (amabhlogo e-carbon) kuthuthukisa kakhulu ukumelana nokugqwala kwensimbi encibilikisiwe futhi kuyindlela yokusebenzisa izitini ze-aluminium carbon ezinhlelweni zokwenza insimbi. Okwesibili, izitini ze-aluminium carbon nazo zisetshenziswa ekwelashweni kwensimbi encibilikisiwe kanye nasezitsheni zompompi.

Izitini ze-aluminium carbon zokwelashwa kwensimbi encibilikisiwe

Izitini ze-aluminium silicon carbide zisetshenziswa kakhulu emishinini yokuthutha insimbi encibilikisiwe njengethangi lensimbi encibilikisiwe. Kodwa-ke, uma lolu hlobo lwezinto eziphikisayo lusetshenziswa emathangini amakhulu ensimbi encibilikisiwe kanye nabaxubi bensimbi, futhi luhlangabezana nezimo ezinzima zokushisa nokupholisa, luvame ukuqhekeka, okuholela ekuqhekekeni kwesakhiwo. Ngaphezu kwalokho, ngoba izitini ze-Al2O3-SiC-C ezisetshenziswa emathangini amakhulu ensimbi eshisayo kanye nabaxubi bensimbi zivame ukuba nokuqukethwe kwekhabhoni okungu-15% kanye nokuqhuba kokushisa okuphezulu njengo-17~21W/(m·K) (800℃), kukhona ukwehla kwezinga lokushisa lensimbi encibilikisiwe kanye nenkinga yokuguqula amashidi ensimbi emathangi amakhulu ensimbi encibilikisiwe kanye nezimoto ezixubayo. Isinyathelo sokumelana nalokhu ukufeza ukuqhuba kokushisa okuphansi ngokususa i-SiC, ingxenye eqhuba ukushisa kakhulu, ngenkathi kunciphisa okuqukethwe kwe-graphite kanye nokucwenga i-graphite.

Ngocwaningo oluyisisekelo, kuphethwa ngokuthi:

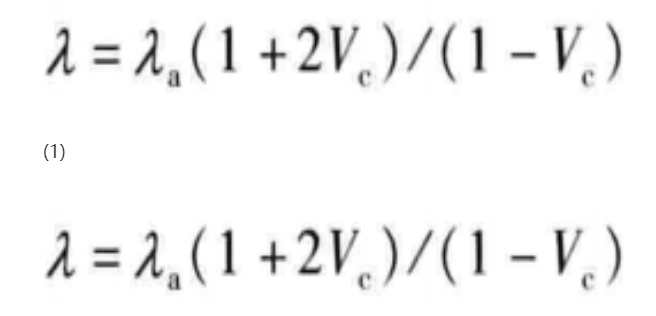

(1) Uma okuqukethwe kwe-graphite (ingxenye yesisindo) ezitini ze-aluminium carbon kungaphansi kuka-10%, isakhiwo sayo senhlangano sakhiwe yi-Al2O3 eyakha i-matrix eqhubekayo, futhi i-carbon igcwaliswa ku-matrix ngesimo sezinkanyezi. Ngalesi sikhathi, i-thermal conductivity λ yesitini se-aluminium carbon ingabalwa cishe ngefomula (1)

Kule fomula, i-λa iwukuqhutshwa kokushisa kwe-Al2O3; i-Vc iyingxenyana yevolumu ye-graphite. Lokhu kubonisa ukuthi ukuqhutshwa kokushisa kwezitini ze-aluminium carbon akuhlobene nokuqhuba kokushisa kwe-graphite.

(2) Uma i-graphite icwengisiswa, ukuhanjiswa kokushisa kwesitini se-aluminium carbon akuncikile kakhulu ezinhlayiyeni ze-graphite.

(3) Ezitini ze-aluminium-carbon ezinekhabhoni ephansi, lapho i-graphite ihluzwa, kungakhiwa i-dense bonding matrix, engathuthukisa ukumelana nokugqwala kwezitini ze-aluminium-carbon.

Lokhu kukhombisa ukuthi izitini ze-aluminium carbon eziphansi ze-A zingakwazi ukuzivumelanisa nezimo zokusebenza zamathangi amakhulu ensimbi eshisayo kanye nezimoto zokuxuba insimbi ohlelweni lokwenza insimbi.

Isikhathi sokuthunyelwe: Feb-27-2024