1. High-aluminum castable:I-high-aluminium castable ikakhulukazi yakhiwe i-alumina (i-Al2O3) futhi inokuphikisa okuphezulu, ukumelana ne-slag kanye nokumelana nokushaqeka okushisayo. Isetshenziswa kabanzi ezitsheni zokushisa ezishisa kakhulu nasezindaweni ezishisayo ensimbi, izinsimbi ezingenayo insimbi, amakhemikhali nezinye izimboni.

2. Ifayibha yensimbi eqinisiwe iyacastable:I-Steel fiber reinforced castable isekelwe kuma-castable ajwayelekile futhi imicu yensimbi yengezwa ukuthuthukisa ukumelana kwayo nokushaqeka okushisayo, ukumelana nokugqoka kanye nokumelana ne-slag. Isetshenziswa kakhulu kwiziko, izisekelo zomlilo nezinye izingxenye ezimbonini zensimbi, i-metallurgy, petrochemical nezinye.

3. I-Mullite iyasakazwa:I-Mullite castable ikakhulukazi yakhiwe nge-mullite (MgO·SiO2) futhi inokumelana okuhle nokugqokwa, i-refractoriness kanye nokumelana ne-slag. Ivamise ukusetshenziswa ezingxenyeni ezibalulekile ezifana neziko lokwenza insimbi neziguquli ezimbonini zensimbi, ezensimbi nezinye.

4. I-silicon carbide iyasakazwa:I-Silicon carbide castable yakhiwa ikakhulukazi i-silicon carbide (SiC) futhi inokumelana okuhle nokugqokwa, ukumelana ne-slag kanye nokumelana nokushaqeka okushisayo. Isetshenziswa kakhulu kwiziko lokushisa eliphezulu, imibhede yesithando somlilo nezinye izingxenye zezinsimbi ezingenayo insimbi, amakhemikhali, izitsha zobumba nezinye izimboni.

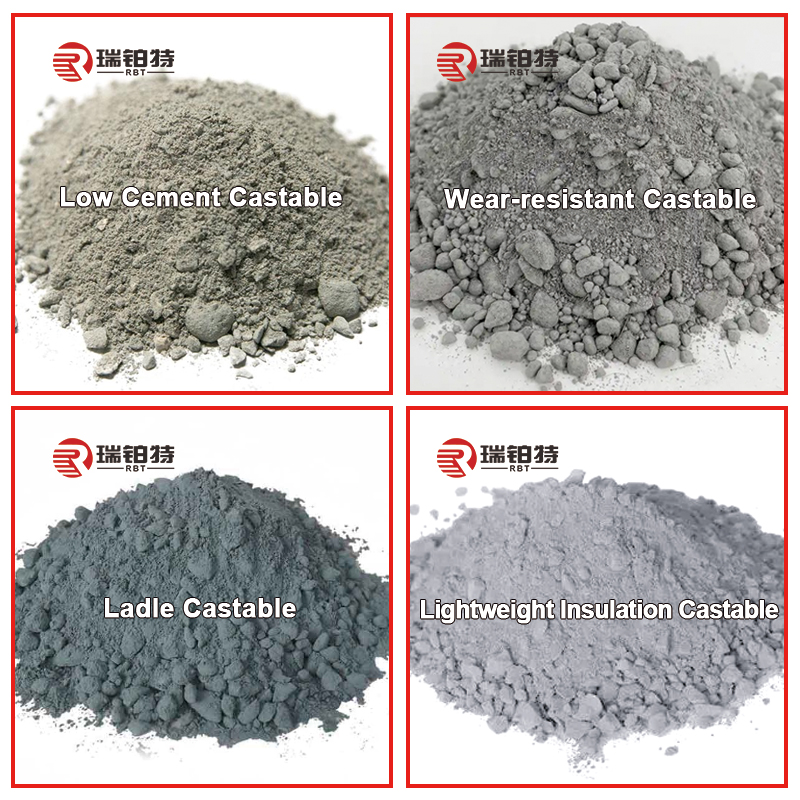

5. Izinsimbi zikasimende ophansi:ibhekisela ezintweni ezifakwayo ezinosimende ophansi, ngokuvamile ezingaba ngu-5%, kanti ezinye zehliswa zibe ku-1% ziye ku-2%. Ama-castable kasimende aphansi asebenzisa izinhlayiya ze-ultra-fine ezingadluli ku-1μm, futhi ukumelana nokushaqeka kwazo okushisayo, ukumelana ne-slag nokumelana nokuguguleka kuthuthukiswa kakhulu. Ama-castables aphansi-samente afaneleka kuma-linings ahlukahlukene okushisa ukushisa, ukushisa okushisa, ama-vertical kilns, ama-rotary kilns, izembozo zomlilo kagesi, izimbobo zokudonsa isithando somlilo, njll; izinsimbi ezizigelezayo ezinosimende ophansi zilungele izibhamu ezifuthwayo ezihlanganisiwe ze-spray metallurgy, i-high-temperature-resistant linings ye-petrochemical catalytic cracking reactors, kanye nezindwangu zangaphandle zokufudumeza amapayipi okupholisa amanzi esithandweni somlilo.

6. Ama-castable aphikisayo angagugi:Izingxenye eziyinhloko zama-refractory castables angakwazi ukuguga zihlanganisa ama-refractory aggregates, izimpushana, izithasiselo nezibophezelo. Ama-refractory castables angagqoki awuhlobo lwe-amorphous refractory material esetshenziswa kabanzi ku-metallurgy, amakhemikhali e-petrochemicals, izinto zokwakha, amandla nezinye izimboni. Le nto inezinzuzo zokumelana nokushisa okuphezulu, ukumelana nokugqoka, nokumelana nokuguguleka. Isetshenziselwa ukulungisa nokuvikela ulwelwesi lwemishini yokushisa ephezulu njengeziko nama-boilers ukuze kwandiswe impilo yesevisi yemishini.

7. I-Ladle castable:I-Ladle castable iyi-amorphous refractory castable eyenziwe ngekhwalithi ephezulu ye-alumina bauxite clinker kanye ne-silicon carbide njengezisetshenziswa eziyinhloko, ene-aluminate cement binder ehlanzekile, i-disperant, i-ejenti yokuvimbela ukushwabana, i-coagulant, i-fiber-proof-proof kanye nezinye izithasiselo. Ngenxa yokuthi inomphumela omuhle ongqimbeni olusebenzayo lwe-ladle, ibizwa nangokuthi i-aluminium silicon carbide castable.

8. I-insulating refractory engasindi eyakhiwe:I-Lightweight insulating refractory castable i-refractory castable enesisindo esilula, amandla aphezulu kanye nokusebenza okuhle kakhulu kwe-thermal insulation. Ikakhulukazi yakhiwe ngama-aggregates angasindi (afana ne-perlite, i-vermiculite, njll.), izinto ezizinzile ezinezinga lokushisa eliphezulu, izibophezelo nezithasiselo. Isetshenziswa kabanzi emishinini yezimboni esezingeni eliphezulu, njengeziko lezimboni, izindawo zokushisa ukushisa, iziko lensimbi, iziko elincibilikisa ingilazi, njll., ukuthuthukisa ukusebenza kahle kokusetshenziswa kwamandla kwemishini kanye nokunciphisa ukusetshenziswa kwamandla.

9. Corundum castable:Ngokusebenza kwayo okuhle kakhulu, i-corundum castable isiphenduke inketho efanelekile yezingxenye ezibalulekile zamakhilo ashisayo. Izici ze-corundum castable zingamandla aphezulu, izinga lokushisa eliphezulu lokuthambisa umthwalo kanye nokumelana okuhle kwe-slag, njll. Izinga lokushisa elijwayelekile lokusetshenziswa yi-1500-1800℃. .

10. Magnesium castable:Isetshenziswa kakhulu emishinini yokushisa eshisa kakhulu, inokumelana kahle kakhulu nokugqwala kwe-alkaline slag, inkomba engaba namandla komoya-mpilo ephansi futhi akukho ukungcoliswa kwensimbi encibilikisiwe. Ngakho-ke, inamathuba amaningi okufaka isicelo embonini ye-metallurgical, ikakhulukazi ekukhiqizeni insimbi ehlanzekile kanye nomkhakha wezinto zokwakha. .

11. Okwenziwa ngobumba:Izingxenye eziyinhloko ziyi-clinker yobumba kanye nobumba oluhlanganisiwe, ngokuzinza okuhle kokushisa kanye nokwenqaba okuthile, futhi intengo iphansi kakhulu. Ivame ukusetshenziselwa ulwelwesi lwama-kilns ezimboni ezijwayelekile, njengezithando zokushisa, ama-annealing furnaces, ama-boilers, njll. Ingakwazi ukumelana nokushisa okuthile komthwalo wokushisa futhi ibambe iqhaza ekuvimbeleni ukushisa nokuvikela umzimba wesithando somlilo.

12. Ama-castable omile:Ama-castables awomile akhiwe ikakhulukazi ama-refractory aggregates, ama-powder, ama-binders namanzi. Izithako ezijwayelekile zifaka i-clay clinker, i-tertiary alumina clinker, impushana ye-ultrafine, usimende we-CA-50, ama-disperants nama-siliceous noma ama-feldspar angenakunyakaziswa.

Ama-castables omile angahlukaniswa abe yizinhlobo eziningi ngokuya ngokusetshenziswa kwawo kanye nezithako. Isibonelo, ama-castables omile angangenisi asetshenziswa ikakhulukazi kumaseli e-aluminium electrolytic, angavimbela ngokuphumelelayo ukungena kwama-electrolyte futhi andise impilo yesevisi yamaseli. Ngaphezu kwalokho, ama-castables e-refractory eyomile afanele i-hardware, ukuncibilika, imboni yamakhemikhali, izinsimbi ezingezona ayoni nezinye izimboni, ikakhulukazi embonini yensimbi, njenge-rotary kiln front holn mouth, isithando somlilo sokuhlakazeka, isembozo sekhanda lekhanda nezinye izingxenye.

Isikhathi sokuthumela: May-26-2025