Emkhakheni wezimboni oshisa kakhulu, ukusebenza kwezinto zokubopha uthango lwe-oven kuthinta ngqo ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo. Njengommeleli wezinto ezisebenza kahle kakhulu zokungaguquki, izitini ze-magnesia-alumina spinel, ezinezakhiwo zazo ezinhle kakhulu eziphelele, sezibe ukukhetha okuhle kakhulu kwezimboni ezifana nensimbi, ingilazi, kanye nosimende ukumelana nokuguguleka kokushisa okuphezulu nokwandisa isikhathi sokuphila kwemishini, okunikeza ukwesekwa okuthembekile kokukhiqizwa kwezimboni okushisa okuphezulu.

Ukuhola Imboni Ngokusebenza Okuhle Kakhulu

Izitini ze-Magnesia-alumina spinel zenziwe nge-magnesia ne-aluminium oxide ngezinqubo ezikhethekile. Isakhiwo sazo esiyingqayizivele sekristalu sizinikeza izinzuzo zokusebenza ezinamandla. Lezi zitini zibonisa ukumelana okuvelele kokushisa okuphezulu, ezikwazi ukumelana namazinga okushisa aphezulu afinyelela ku-1800°C. Ngisho nasezindaweni ezishisa kakhulu isikhathi eside, zigcina izakhiwo zomzimba nezimakhemikhali ezizinzile, zivimbela ngempumelelo ukulimala kwezingxenye ze-oven okubangelwa amazinga okushisa aphezulu.

Ukumelana nokushaqeka kokushisa kuyisici esiphawulekayo sezitini ze-magnesia-alumina spinel. Ngesikhathi sokushisa nokupholisa okuvamile kwama-oven, izinto ezivamile zokuphikisa zivame ukuqhekeka nokuqhekeka ngenxa yokucindezeleka kokushisa. Kodwa-ke, ngenxa yokwanda kwazo okuphansi kokushisa kanye nokuqina okuhle, izitini ze-magnesia-alumina spinel zinganciphisa ngempumelelo imiphumela yokucindezeleka kokushisa, zinciphise kakhulu ingozi yokulimala kokushaqeka kokushisa, zandise isikhathi senkonzo, futhi zinciphise isikhathi sokungasebenzi kwe-oven ukuze kulungiswe.

Izitini ze-Magnesia-alumina spinel nazo zisebenza kahle kakhulu ekuvikeleni ukuguguleka kwamakhemikhali. Zinokumelana okuhle kakhulu ne-alkaline ne-acidic slag, kanye namagesi okushisa okuphezulu, zivimbela ngempumelelo ukungena kwezinto eziyingozi futhi zivikele ukuphepha kwesakhiwo sama-oven. Kungakhathaliseki ukuthi zisendaweni ene-alkaline kakhulu yokuncibilikisa insimbi noma isimo se-acidic esiphezulu sokukhiqizwa kwengilazi, zingafeza imisebenzi yazo yokuvikela ngokuzinzile.

Izicelo Ezijulile Kuzo Zonke Izimboni Eziningi

Embonini yensimbi, izitini ze-magnesia-alumina spinel zisetshenziswa kabanzi ezindaweni ezibalulekile zama-converter, ama-ladle, nama-tundishes. Ngesikhathi sokwenza insimbi yama-converter, zingamelana nokukhuhla nokuguguleka kwensimbi encibilikisiwe eshisa kakhulu kanye ne-slag, okuqinisekisa ubuqotho be-lining ye-converter. Uma zisetshenziswa kuma-ladle nama-tundishes, zinganciphisa ngempumelelo ukusabela phakathi kwensimbi encibilikisiwe nezinto zokubopha, zithuthukise ubumsulwa bensimbi encibilikisiwe, futhi zithuthukise ikhwalithi yensimbi. Ngemva kokuba ibhizinisi elikhulu lensimbi lamukele izitini ze-magnesia-alumina spinel, impilo yenkonzo yama-ladles ayo yanda kusukela kuma-heats angu-60 kuya kuma-heats angu-120, okunciphisa kakhulu izindleko zokukhiqiza.

Embonini yokukhiqiza ingilazi, izitini ze-magnesia-alumina spinel ziyizinto ezikhethwayo zezingxenye ezibalulekile zama-oven engilazi. Ezindaweni ezishisayo kanye nabahlaziyi bezitofu zokuncibilikisa ingilazi, zingamelana nokuguguleka kokuncibilika kwengilazi okushisa okuphezulu kanye nokukhuhla amagesi okushisa okuphezulu, zigcine ukuqina kwesakhiwo sesitofu, zinciphise imvamisa yokugcinwa kwesitofu, futhi zithuthukise ukuqhubeka nokuzinza kokukhiqizwa kwengilazi. Ngemva kokusebenzisa izitini ze-magnesia-alumina spinel, umjikelezo wokulungisa izitofu zengilazi ungandiswa ngeminyaka emi-2 kuya kwemi-3, kuthuthukiswe ngempumelelo izinzuzo zomnotho zamabhizinisi.

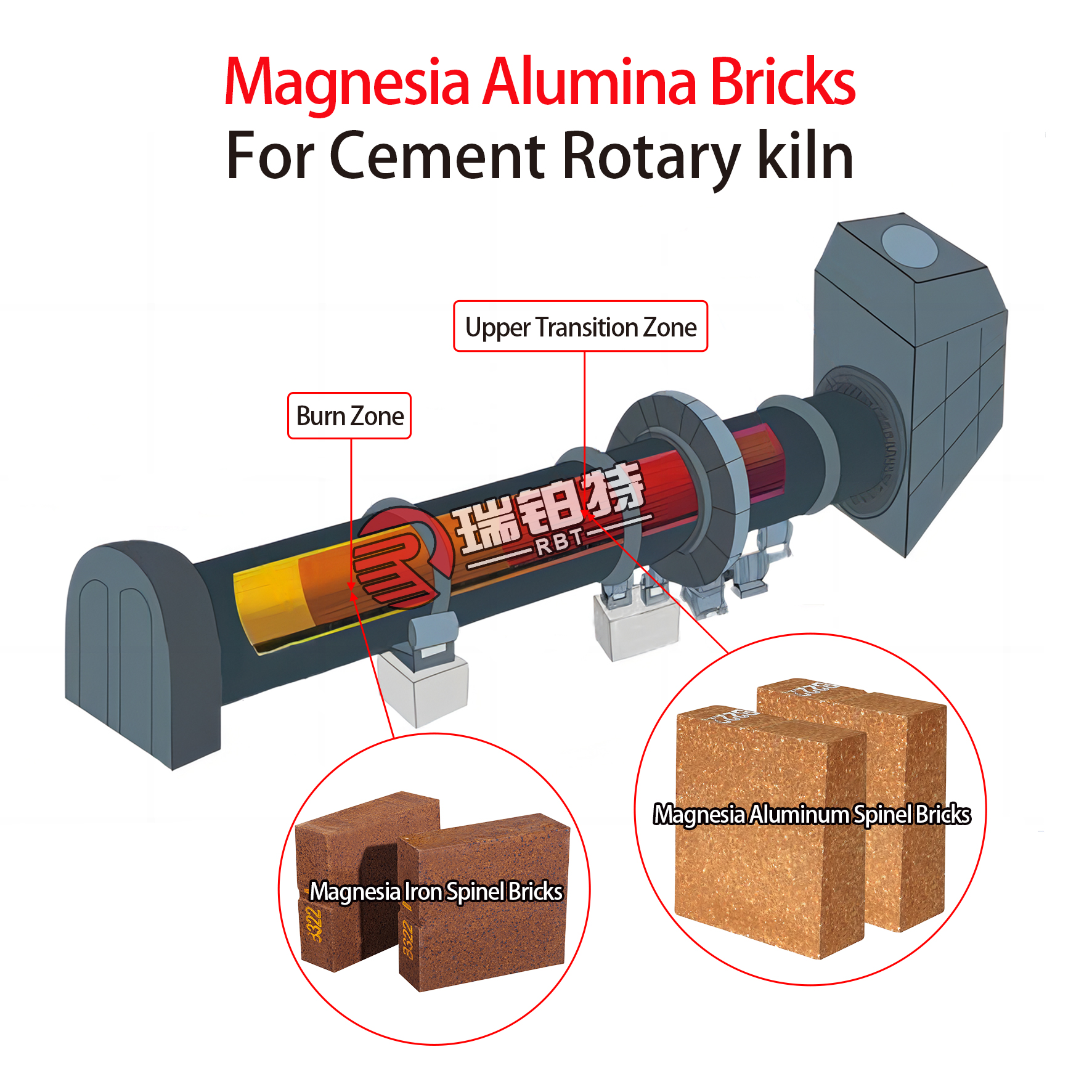

Ngesikhathi sokukhiqizwa kwesamente, indawo yokushisa ephezulu yama-rotary oil ...

Umhlahlandlela Wokuthenga Ochwepheshe

Uma ukhetha izitini ze-magnesia-alumina spinel, amaphuzu alandelayo abalulekile kufanele agcizelelwe: Okokuqala, naka ukwakheka kwamakhemikhali kanye nokwakheka kwamaminerali kwezinto. Izinto zokusetshenziswa ze-magnesia ne-aluminium oxide ezihlanzekile kakhulu zingaqinisekisa ukusebenza okuzinzile kwezitini. Okwesibili, gxila ezinkombeni zokusebenza ezibonakalayo zemikhiqizo, njengobuningi obukhulu, ukuvuleka okubonakalayo, kanye namandla okuchoboza abandayo ekushiseni kwegumbi. Lezi zinkomba zibonisa ngqo ikhwalithi nokuqina kwezitini. Okwesithathu, hlola inqubo yokukhiqiza kanye nohlelo lokulawula ikhwalithi lwabaphakeli. Khetha abaphakeli abanemishini yokukhiqiza ethuthukisiwe, izinqubo zokuhlola eziphelele, kanye nokuhlangenwe nakho okucebile embonini ukuqinisekisa ikhwalithi yomkhiqizo ethembekile. Ngaphezu kwalokho, ngokwezimo zokusebenza ezithile, ukunemba kobukhulu kanye nokuzivumelanisa nesimo kwezitini nakho kudingeka kucatshangelwe ukuqinisekisa ukwakhiwa okubushelelezi nokufakwa.

Ngenxa yokusebenza kwazo okuvelele kanye nokusetshenziswa okubanzi, izitini ze-magnesia-alumina spinel sezibe yizinto ezibaluleke kakhulu ezivimbela ukusebenza kahle kwezimboni ezishisa kakhulu. Kungakhathaliseki ukuthi ukuthuthukisa ukusebenza kahle kokukhiqiza, ukunciphisa izindleko, noma ukuqinisekisa ikhwalithi yomkhiqizo, zinganikeza izixazululo ezithembekile zamabhizinisi. Xhumana nathi manje ukuthola ulwazi lomkhiqizo wobungcweti kanye nezinsizakalo ezenziwe ngokwezifiso, futhi masivikele umkhiqizo wakho wezimboni oshisa kakhulu!

Isikhathi sokuthunyelwe: Juni-23-2025