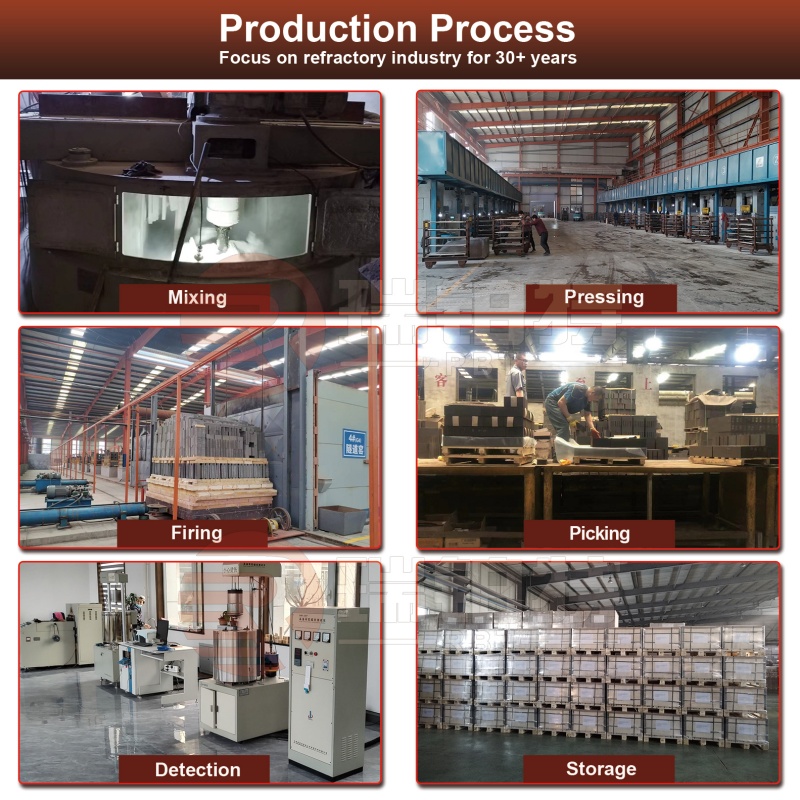

Emkhakheni wezitofu zezimboni ezishisa kakhulu (njengeziguquli zokwenza insimbi, amaladle, kanye nezitofu zokuqhuma),izitini ze-magnesium carbonZivelele njengezinto eziyinhloko ezimelana nokugqwala, ngenxa yokumelana kwazo okuhle kakhulu nokugqwala, ukuqina kwezinga lokushisa eliphezulu, kanye nokumelana nokushaqeka kokushisa. Inqubo yokukhiqiza yalezi zitini iyinhlanganisela eqinile yobuchwepheshe kanye nokunemba—isinyathelo ngasinye sinquma ngqo ikhwalithi yokugcina yomkhiqizo. Ngezansi, sikuyisa emsebenzini ophelele wokukhiqiza izitini ze-magnesium carbon, siveza ukuthi siqinisekisa kanjani ukuthi zonke izitini ziyahlangabezana nezindinganiso zezinga lezimboni.

1. Ukukhethwa Kwezinto Ezingavuthiwe: Isisekelo Sezitini Zekhabhoni Ze-Magnesium Ezisezingeni Eliphezulu

Ikhwalithi yezinto zokusetshenziswa iyindlela yokuqala yokuvikela ukusebenza kwezitini ze-magnesium carbon. Silandela imigomo yokukhetha eqinile ukuqinisekisa ukuthi ingxenye ngayinye ihlangabezana nezindinganiso eziphakeme:

I-Magnesia Aggregate Ehlanzekile Kakhulu:Sisebenzisa i-fused magnesia noma i-sintered magnesia enokuqukethwe kwe-MgO okungaphezu kuka-96%. Lokhu okuluhlaza kunikeza isitini ukumelana okunamandla okushisa okuphezulu kanye nokumelana nokugqwala, okumelana ngempumelelo nokuguguleka kwensimbi encibilikisiwe kanye ne-slag ezitsheni.

Umthombo Wekhabhoni Osezingeni Eliphezulu:Kukhethwe i-graphite yemvelo enamafutha anokuqukethwe kwekhabhoni okungu-90%+ . Isakhiwo sayo esinezingqimba sithuthukisa ukumelana nokushisa kwesitini, kunciphisa ingozi yokuqhekeka ngenxa yokushintsha kwezinga lokushisa okusheshayo ngesikhathi sokusebenza kwesithando somlilo.

I-Premium Binder:I-resin ye-phenolic (eguquliwe ukuze ikwazi ukumelana nokushisa okuphezulu) isetshenziswa njenge-binder. Iqinisekisa ukuhlangana okuqinile phakathi kwe-magnesia ne-graphite, kuyilapho igwema ukuguquguquka noma ukubola emazingeni okushisa aphezulu, okungathinta ubuqotho besitini.

Izithasiselo Zokulandelela:Inani elincane lama-antioxidants (njenge-aluminium powder, i-silicon powder) kanye nezinsiza zokusila ziyangezwa ukuvimbela i-graphite oxidation nokuthuthukisa ubuningi bezitini. Zonke izinto zokusetshenziswa zihlolwa izikhathi ezintathu ukuze kususwe ukungcola okungase kunciphise ukusebenza.

2. Ukuchoboza Nokugoqa: Ukulawula Usayizi Wezinhlayiyana Ngokuqondile Kwesakhiwo Esifanayo

Ukusatshalaliswa kosayizi wezinhlayiya ezifanayo kuyisihluthulelo sokuqinisekisa ubuningi namandla ezitini ze-magnesium carbon. Lesi sigaba silandela imingcele eqinile yobuchwepheshe:

Inqubo Yokuchoboza:Okokuqala, amabhlogo amakhulu e-magnesia kanye ne-graphite kuchotshozwa kube yizinhlayiya ezincane kusetshenziswa ama-jaw crushers kanye nama-impact crushers. Ijubane lokuchotshozwa lilawulwa ku-20-30 rpm ukuze kugwenywe ukushisa ngokweqile kanye nomonakalo esakhiweni sezinto zokusetshenziswa.

Ukuhlola Nokuhlela:Izinto ezichotshoziwe zivivinywa ngezikrini ezidlidlizayo ezinezingqimba eziningi (ezinosayizi we-mesh ongu-5mm, 2mm, no-0.074mm) ukuze zihlukaniswe zibe ama-aggregate amakhulu (3-5mm), ama-aggregate aphakathi (1-2mm), ama-aggregate amahle (0.074-1mm), kanye nama-powder amahle kakhulu (<0.074mm). Iphutha losayizi wezinhlayiya lilawulwa ngaphakathi kuka-±0.1mm.

Ukuhlanganiswa kwe-granule:Ubukhulu obuhlukene bezinhlayiya buxutshwa ku-mixer enesivinini esikhulu imizuzu eyi-10-15 ngesivinini esingu-800 rpm. Lokhu kuqinisekisa ukuthi inqwaba ngayinye yama-granule inokwakheka okufanayo, okubeka isisekelo sobuningi bezitini obufanayo.

3. Ukuxuba Nokuxova: Ukufinyelela Ukubopha Okuqinile Phakathi Kwezingxenye

Isigaba sokuxuba nokuxova sinquma amandla okubopha phakathi kwezinto zokusetshenziswa. Sisebenzisa abaxubi be-double-helix abathuthukisiwe futhi silawula ngokuqinile izimo zenqubo:

Ukuxuba Izinto Ezomile Ngaphambi Kokuqala:Ama-aggregate amakhulu, aphakathi nendawo, kanye nama-fine aqala ngokuxubaniswa omile imizuzu emi-5 ukuqinisekisa ukusatshalaliswa ngokulinganayo kwengxenye ngayinye. Lesi sinyathelo sigwema ukugcwala kwekhabhoni noma i-magnesia endaweni, okungadala umehluko ekusebenzeni.

Ukwengeza i-Binder kanye ne-Kneading:I-resin ye-phenolic eguquliwe (efudunyezwa ku-40-50℃ ukuze kube nokugeleza okungcono) yengezwa engxubeni eyomile, kulandelwe imizuzu engama-20-25 yokuxova. Izinga lokushisa lomxube ligcinwa ku-55-65℃, futhi ingcindezi ilawulwa ku-0.3-0.5 MPa—lokhu kuqinisekisa ukuthi i-binder igoqa ngokuphelele inhlayiya ngayinye, yakha isakhiwo esizinzile se-"magnesia-graphite-binder".

Ukuhlolwa Kokungaguquguquki:Ngemva kokuxova, ukuqina kwengxube kuhlolwa njalo ngemizuzu eyi-10. Ukuqina okufanele kungama-30-40 (kulinganiswa ngemitha ejwayelekile yokuvumelana); uma komile kakhulu noma kumanzi kakhulu, isilinganiso se-binder noma isikhathi sokuxova silungiswa ngesikhathi sangempela.

4. Ukwakhiwa Kwama-Press: Ukubumba Okuphezulu Kokucindezela Kokubanzi Namandla

Ukwakha i-press forming yisinyathelo esinikeza izitini ze-magnesium carbon ukuma kwazo kokugcina futhi siqinisekise ukuminyana okuphezulu. Sisebenzisa imishini yokucindezela ye-hydraulic ezenzakalelayo enokulawula ukucindezela okunembile:

Ukulungiselela Isikhunta:Izikhunta zensimbi ezenziwe ngokwezifiso (ngokuya ngezidingo zamakhasimende ngobukhulu bezitini, njengo-230×114×65mm noma osayizi ababunjwe ngendlela ekhethekile) ziyahlanzwa futhi zimbozwe nge-ejenti yokukhulula ukuvimbela ingxube ukuthi inamathele kusikhunta.

Ukucindezela Okuphezulu:Ingxube exoviwe ithululelwa esikhumbeni, bese umshini wokucindezela we-hydraulic usebenzisa ingcindezi engu-30-50 MPa. Isivinini sokucindezela sisethwe ku-5-8 mm/s (ukucindezela kancane ukuze kususwe amabhamuza omoya) futhi sibanjwe imizuzwana emi-3-5. Le nqubo iqinisekisa ukuthi ubukhulu besitini bufinyelela ku-2.8-3.0 g/cm³, kanye ne-porosity engaphansi kuka-8%.

Ukususwa Nokuhlolwa:Ngemva kokucindezela, izitini ziyasuswa ngokuzenzakalelayo futhi zihlolwe ukuthi azinazo yini izinkinga ezingaphezulu (ezifana nokuqhekeka, imiphetho engalingani). Izitini ezinezinkinga ziyanqatshwa ngokushesha ukuze kugwenywe ukungena enkambisweni elandelayo.

5. Ukwelashwa Kokushisa (Ukwelapha): Ukuthuthukisa Ukubopha Nokuzinza Kwe-Binder

Ukwelashwa ngokushisa (ukuphulukisa) kuqinisa umphumela wokubopha we-binder futhi kususa izinto ezishintshayo ezitini. Sisebenzisa ama-tunnel kilns anokulawula izinga lokushisa okunembile:

Ukushisa Okuhamba Ngezinyathelo: Izitini zibekwa kuhhavini womhubhe, bese izinga lokushisa liphakanyiswa kancane kancane:

20-80℃ (amahora ama-2):Hlikihla umswakama womphezulu;

80-150℃ (amahora ama-4):Khuthaza ukuphulukiswa kwe-resin kwangaphambili;

150-200℃ (amahora ayi-6):Ukuhlanganisa nokulungisa i-resin ngokuphelele;

200-220℃ (amahora ama-3):Qinisa isakhiwo sezitini.

Izinga lokushisa lilawulwa ku-10-15℃/ihora ukuvimbela ukuqhekeka ngenxa yokucindezeleka kokushisa.

Ukususwa Kwezinto Eziguquguqukayo:Ngesikhathi sokulungisa, izingxenye eziguquguqukayo (njengezinhlayiya ezincane zama-molecule) zikhishwa ngohlelo lokukhipha umoya lwe-oven yesitofu, okuqinisekisa ukuthi isakhiwo sangaphakathi sesitini siminyene futhi asinazo izikhala.

Inqubo Yokupholisa: Ngemva kokuphola, izitini zipholiswa zifinyelele ekushiseni kwegumbi ngesilinganiso esingu-20℃/ihora. Ukupholisa okusheshayo kuyagwenywa ukuvimbela umonakalo wokushaqeka kokushisa.

6. Ukuhlolwa Kwekhwalithi Ngemva Kokucubungula: Ukuqinisekisa ukuthi Izitini Zonke Ziyahlangabezana Nezindinganiso

Isigaba sokugcina sokukhiqiza sigxile ekucutshungulweni okunembile kanye nokuhlolwa kwekhwalithi okuqinile ukuqinisekisa ukuthi isitini ngasinye se-magnesium carbon sihlangabezana nezidingo zokusetshenziswa kwezimboni:

Ukugaya Nokunquma:Izitini ezinemiphetho engalingani ziyagaywa kusetshenziswa imishini yokugaya ye-CNC, okuqinisekisa ukuthi iphutha lobukhulu lingaphakathi kuka-±0.5mm. Izitini ezinesimo esikhethekile (njengezitini ezinesimo se-arc zabaguquli) zicutshungulwa kusetshenziswa izikhungo zokugaya ezine-axis ezi-5 ukuze zifane nejika elingaphakathi lodonga lwesithando.

Ukuhlolwa Kwekhwalithi Okuphelele:Iqoqo ngalinye lezitini lidlula ezivivinyweni ezi-5 ezibalulekile:

Ukuhlolwa Kobuningi kanye Nokugoba:Usebenzisa indlela ye-Archimedes, qinisekisa ukuthi ubukhulu be-bulk buyi-≥2.8 g/cm³ kanye ne-porosity ≤8%.

Ukuhlolwa Kwamandla Okucindezela:Hlola amandla okucindezela esitini (≥25 MPa) usebenzisa umshini wokuhlola ojwayelekile.

Ukuhlolwa Kokumelana Nokushaqeka Kokushisa:Ngemva kwemijikelezo eyi-10 yokushisa (1100℃) nokupholisa (izinga lokushisa legumbi), hlola imifantu (akukho mifantu ebonakalayo evunyelwe).

Ukuhlolwa Kokumelana Nokugqwala:Lingisa izimo zesithando somlilo ukuze uhlole ukumelana kwezitini nokuguguleka kwe-slag encibilikisiwe (izinga lokuguguleka ≤0.5mm/h).

Ukuhlaziywa Kokwakheka Kwamakhemikhali:Sebenzisa i-X-ray fluorescence spectrometry ukuqinisekisa okuqukethwe yi-MgO (≥96%) kanye nokuqukethwe kwekhabhoni (8-12%).

Ukupakisha Nokugcina:Izitini ezifanele zipakishwa emabhokisini angangeni umswakama noma emaphalethini okhuni, kanye nefilimu engangeni umswakama eboshwe nxazonke ukuze kugwenywe ukumuncwa komswakama ngesikhathi sokuthuthwa. Iphakheji ngayinye ilebula enenombolo yebhetshi, usuku lokukhiqiza, kanye nesitifiketi sokuhlolwa kwekhwalithi ukuze kulandeleke.

Kungani Kufanele Ukhethe Izitini Zethu Ze-Magnesium Carbon?

Inqubo yethu yokukhiqiza eqinile (kusukela ekukhetheni izinto zokusetshenziswa kuya ekucutshungulweni kwangemva kokucubungula) iqinisekisa ukuthi izitini zethu ze-magnesium carbon zisebenza kahle kakhulu ezitsheni zezimboni ezishisa kakhulu. Kungakhathaliseki ukuthi zingomshini wokuguqula insimbi, ama-ladle, noma eminye imishini eshisa kakhulu, imikhiqizo yethu ingakwazi:

Imelana namazinga okushisa afinyelela ku-1800℃ ngaphandle kokuthambisa noma ukuguquka.

Melana nokuguguleka kwensimbi encibilikisiwe kanye ne-slag, okwandisa impilo yesevisi yesithando ngo-30%+.

Nciphisa imvamisa yokulungisa kanye nezindleko zokukhiqiza kumakhasimende.

Sinikeza izixazululo ezenziwe ngokwezifiso ngokuya ngohlobo lwesithando sakho, usayizi, kanye nezimo zokusebenza. Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nenqubo yethu yokukhiqiza izitini ze-magnesium carbon noma ukuthola isilinganiso samahhala!

Isikhathi sokuthunyelwe: Okthoba-29-2025