Izinzuzo ze-magnesia carbon brick yilezi:ukumelana nokuguguleka kwe-slag kanye nokumelana nokushaqeka okuhle kokushisa. Esikhathini esedlule, ukonakala kwezitini ze-MgO-Cr2O3 nezitini ze-dolomite kwakuwukuthi zazimunca izingxenye ze-slag, okuholela ekuqhekekeni kwesakhiwo, okuholela ekulimaleni ngaphambi kwesikhathi. Ngokungeza i-graphite, izitini zekhabhoni ze-magnesia zaqeda lokhu kushiyeka. Isici saso ukuthi i-slag ingena kuphela endaweni yokusebenza, ngakho-ke isendlalelo sokusabela Ivalwe endaweni yokusebenza, isakhiwo sinokucwecwa okuncane nempilo ende yesevisi.

Manje, ngaphezu kwezitini ze-asphalt zendabuko kanye ne-resin-bonded magnesia carbon brick (okuhlanganisa nezitini ezishisiwe ze-magnesia ezifakwe uwoyela),the Magnesia carbon izitini ezithengiswa emakethe zihlanganisa:

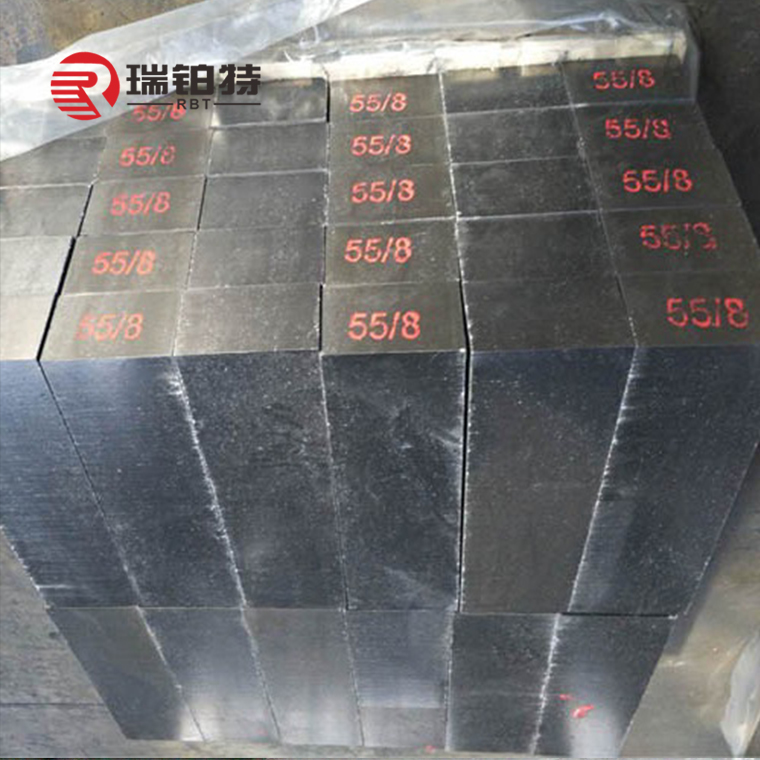

(1) Izitini ze-Magnesia carbon ezenziwe nge-magnesia equkethe i-96% ~ 97% MgO kanye ne-graphite 94% ~ 95% C;

(2) Izitini ze-Magnesia carbon ezenziwe nge-magnesia equkethe 97.5% ~ 98.5% MgO kanye negraphite 96% ~ 97% C;

(3) Izitini ze-Magnesia carbon ezenziwe nge-magnesia equkethe i-98.5% ~ 99% MgO kanye ne-98% ~C graphite.

Ngokusho kokuqukethwe kwekhabhoni, izitini zekhabhoni ze-magnesia zihlukaniswe zibe:

(I) Izitini ze-magnesia ezifakwe uwoyela ezishisiwe (okuqukethwe kwekhabhoni ngaphansi kuka-2%);

(2) Izitini ze-magnesia eziboshwe ngekhabhoni (okuqukethwe kwekhabhoni ngaphansi kuka-7%);

(3) I-Synthetic resin eboshiwe isitini sekhabhoni ye-magnesia (okuqukethwe kwekhabhoni kungu-8%~20%, kufika ku-25% ezimweni ezimbalwa). Ama-Antioxidants avame ukungezwa ku-asphalt/resin eboshelwe izitini zekhabhoni ye-magnesia (okuqukethwe kwekhabhoni kungu-8% kuya ku-20%).

Izitini ze-Magnesia carbon zikhiqizwa ngokuhlanganisa i-high-purity MgO sand ne-scaly graphite, i-carbon black, njll. Inqubo yokukhiqiza ihlanganisa izinqubo ezilandelayo: ukuchotshozwa kwempahla eluhlaza, ukuhlola, ukulinganisa, ukuxuba ngokuklama kwefomula yezinto ezibonakalayo kanye nokusebenza kokusetha komkhiqizo, ngokuya ngenhlanganisela Izinga lokushisa lohlobo lwe-ejenti liphakanyiswa ukuze lisondele ku-100 ~ 200 ℃ lihlanganiswe ndawonye ne-Mg-called udaka (ingxube yomzimba eluhlaza). Izinto zodaka ze-MgO-C zisebenzisa i-synthetic resin (ikakhulukazi i-phenolic resin) ibunjwa esimweni esibandayo; udaka lwe-MgO-C oluhlanganiswe ne-asphalt (lushiselwa esimweni soketshezi) lubunjwa esimweni esishisayo (cishe i-100 ° C) kwakheka. Ngokuvumelana nosayizi weqoqo kanye nezidingo zokusebenza kwemikhiqizo ye-MgO-C, okokusebenza kwe-vacuum vibration, okokubumbayo okucindezelwayo, ama-extruder, umshini wokunyathelisa we-isostatic, umshini wokunyathelisa oshisayo, okokusebenza kokushisisa, kanye nemishini yokunqamula ingasetshenziswa ukucubungula izinto zodaka ze-MgO-C. kusimo esifanele. Umzimba we-MgO-C owenziwe ufakwa kuhhavini ku-700 ~ 1200 ° C ukuze uthole ukwelashwa okushisa ukuze kuguqulwe i-ejenti ebophayo ibe yikhabhoni (le nqubo ibizwa ngokuthi i-carbonization). Ukuze kwandiswe ukuminyana kwezitini zekhabhoni ye-magnesia futhi kuqinise ukubopha, izigcwalisi ezifana nezibophezelo nazo zingasetshenziswa ukufaka izitini.

Namuhla, i-synthetic resin (ikakhulukazi i-phenolic resin) isetshenziswa kakhulu njenge-ejenti ebophayo yezitini ze-magnesia carbon.Ukusetshenziswa kwe-synthetic resin eboshiwe izitini zekhabhoni ye-magnesia kunezinzuzo eziyisisekelo ezilandelayo:

(1) Izici zemvelo zivumela ukucutshungulwa nokukhiqizwa kwale mikhiqizo;

(2) Inqubo yokukhiqiza imikhiqizo ngaphansi kwezimo zokuxutshwa okubandayo yonga amandla;

(3) Umkhiqizo ungacutshungulwa ngaphansi kwezimo ezingezona ukwelapha;

(4) Uma kuqhathaniswa ne-tiyela asphalt binder, asikho isigaba sepulasitiki;

(5) Ukwenyuka kokuqukethwe kwekhabhoni (ama-graphite amaningi noma amalahle e-bituminous) kungathuthukisa ukumelana nokugqoka kanye nokumelana ne-slag.

Isikhathi sokuthumela: Feb-23-2024