Emsebenzini wezimboni oshisa kakhulu, isidingo sezinto eziqinile, ezingamelani nokushisa asinakuxoxiswana ngaso. Izitini ze-Silicon Carbide (SiC)Zivele njengoshintsho olukhulu, zinikeza ukusebenza okungenakuqhathaniswa ezindaweni ezibucayi kakhulu. Ake sihlole izinhlelo zazo ezahlukahlukene nokuthi kungani ziyisinqumo esiphezulu sezimboni emhlabeni jikelele.

1. Imboni Yezinsimbi

Izitini ze-Silicon Carbide zisetshenziswa kabanzi ezitsheni zensimbi, okuhlanganisa izitofu zokuqhuma, izitofu ze-arc kagesi, kanye ne-ladle linings. Ukumelana kwazo okumangalisayo nokushaqeka kokushisa kanye nendawo yokuncibilika ephezulu (ngaphezu kuka-2700°C) kuzenza zilungele ukumelana nokushintshashintsha kwezinga lokushisa okusheshayo ngesikhathi sokuncibilikisa nokucwenga insimbi. Ziphinde zinciphise ukulahlekelwa ukushisa, zithuthukise ukusebenza kahle kwamandla futhi zehlise izindleko zokusebenza.

2. Ukukhiqizwa kweCeramic neGlasi

Kuma-oven e-ceramic kanye nama-oven e-glass melting, ama-SiC Bricks aphumelela kakhulu ngenxa yokumelana kwawo nokuguguleka okuphezulu kanye nokuqina kwamakhemikhali. Amelana nesenzo sokukhuhla sezinto zokusetshenziswa kanye namagesi agqwalisayo, okuqinisekisa impilo yesithando isikhathi eside kanye nekhwalithi yomkhiqizo eqhubekayo. Kungakhathaliseki ukuthi ukudubula izitsha zobumba noma ingilazi encibilikisayo, lawa ma-brick agcina ubuqotho besakhiwo emazingeni okushisa aphezulu.

3. Ukucubungula Amakhemikhali

Ama-reactor amakhemikhali kanye nama-incinerator avame ukuphatha izinto ezinolaka kanye nokushisa okuphezulu. Izitini ze-Silicon Carbide ziyamelana nokugqwala okuvela kuma-acid, ama-alkali, kanye nosawoti oncibilikisiwe, okwenza zibe yinto ebalulekile ezinqubweni ezifana nokukhiqizwa kwe-sulfuric acid kanye nokushiswa kwemfucuza. Ukubhoboka kwazo okuphansi kuvimbela ukungena kwamakhemikhali, okuqinisekisa ukuphepha nokuqina.

4. Umkhakha Wamandla

Izitshalo zikagesi, ikakhulukazi lezo ezisebenzisa amalahle noma i-biomass, zithembele ku-SiC Bricks ukuze zenze ama-boiler linings kanye nama-heat exchanger. Amandla azo okubekezelela ukucindezeleka okuphezulu kanye nokujikeleza kokushisa kuqinisekisa ukusebenza okuthembekile, kunciphisa isikhathi sokungasebenzi kanye nezidingo zokulungisa. Ngaphezu kwalokho, zisetshenziswa kuma-reactor enuzi ukuze zimelane nemisebe yazo.

5. Izindiza kanye Nokuvikela

Ezisetshenzisweni zezindiza, njengemibhobho yerokhethi kanye nezingxenye zenjini yejethi, izitini zeSilicon Carbide zinikeza ukumelana nokushisa okumangalisayo kanye namandla esakhiwo. Zisetshenziswa futhi ekuzivikeleni ekubekweni kwezikhali kanye nezinhlelo zezikhali ezishisa kakhulu, ngenxa yobunzima bazo kanye nokumelana nokushayisana.

Kungani Ukhetha Izitini Ze-Silicon Carbide?

Ukumelana Nokushaqeka Okushisayo:Imelana nokushintsha kwezinga lokushisa okusheshayo ngaphandle kokuqhekeka.

Amandla Aphezulu:Igcina ubuqotho besakhiwo emazingeni okushisa aphezulu kakhulu.

Ukumelana Nokugqoka:Iyamelana nokuguguleka okuvela ezintweni zokusetshenziswa kanye nokucindezeleka komshini.

Ukuzinza Kwamakhemikhali:Ayithinteki yizinto ezibolile kanye namagesi.

Ukusebenza Kahle Kwamandla:Kunciphisa ukulahleka kokushisa, kunciphisa ukusetshenziswa kukaphethiloli.

Isiphetho

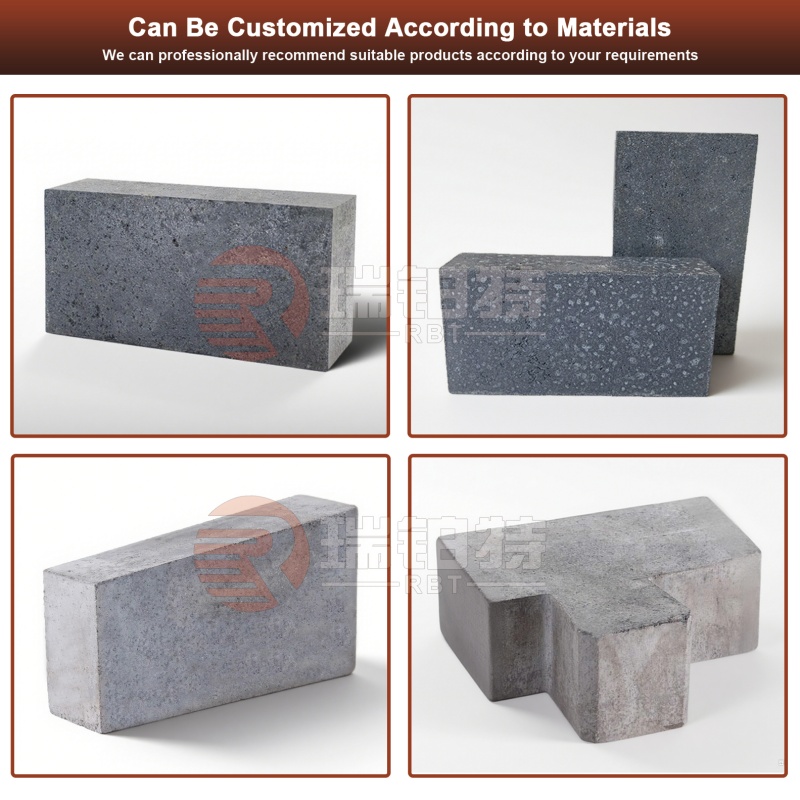

Izitini ze-Silicon Carbide ziyinto eguquguqukayo futhi enokwethenjelwa, eqhuba ukusungula izinto ezintsha kuzo zonke izimboni. Kusukela ekusetshenzisweni kwensimbi kuya ezindiza, izakhiwo zazo ezihlukile ziqinisekisa ukusebenza kahle ezindaweni ezidinga kakhulu. Uma ufuna ukuthuthukisa ukusebenza kahle kwesithando somlilo, ukunciphisa izindleko zokulungisa, nokuthuthukisa ikhwalithi yomkhiqizo, izitini ze-Silicon Carbide ziyisixazululo. Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nezixazululo zethu ze-SiC Brick ezenziwe ngokwezifiso ezenzelwe izidingo zakho zomkhakha.

Isikhathi sokuthunyelwe: Septhemba-09-2025