Ezweni lezinqubo zezimboni ezishisa kakhulu, ukukhetha izingxenye ze-oven kungenza noma kuphule ukusebenza kahle, ikhwalithi, kanye nobude bemisebenzi yakho. Phakathi kwalezi zingxenye ezibalulekile, amapuleti e-oven e-silicon carbide avelele njengesixazululo esishintsha umdlalo, enikeza izinzuzo eziningi ezingaguqula ukusebenza kwe-oven yakho.

Ukumelana Nokushisa Okumangalisayo

I-Silicon carbide (SiC) idume ngezakhiwo zayo ezimangalisayo ezimelana nokushisa. Amapuleti e-kiln enziwe ngale nto ethuthukisiwe angamelana nokushisa okukhulu, avame ukufinyelela ku-1600°C noma ngaphezulu kwezinye izinhlelo zokusebenza ezikhethekile. Lokhu kubekezelela amazinga okushisa aphezulu kuqinisekisa ukuthi amapuleti agcina ubuqotho bawo besakhiwo, ngisho nasezindaweni ze-kiln ezidinga kakhulu. Kungakhathaliseki ukuthi ushisa izinto zobumba, uncibilikisa izinsimbi, noma wenza ezinye izinqubo zokushisa okuphezulu, amapuleti e-kiln e-silicon carbide ahlinzeka ngeplatifomu ethembekile nezinzile engeke igobe, iqhekeke, noma yonakale ngaphansi kokushisa okukhulu.

Ukushisa Okuphezulu

Enye yezinzuzo ezibalulekile zamapuleti esitofu se-silicon carbide ukuthi asebenza kahle kakhulu ekushiseni. I-SiC inokushisa okuphezulu kakhulu uma kuqhathaniswa nezinto zepuleti lesitofu zendabuko ezifana nobumba olungenasici noma i-alumina. Lokhu kusho ukuthi ukushisa kusatshalaliswa ngokushesha nangokulinganayo ebusweni bepuleti, kunciphisa amazinga okushisa ngaphakathi kwesitofu. Ngenxa yalokho, imikhiqizo yakho iphathwa ngokushisa okufanayo, okuholela ekhwalithini ethuthukisiwe, izikhathi zokudubula ezincishisiwe, kanye nokusebenza kahle kwamandla okuthuthukisiwe. Ngamapuleti esitofu se-silicon carbide, ungafinyelela imiphumela ehambisanayo ekusebenzeni kwesitofu sakho, ngenkathi futhi wonga izindleko zamandla ngokuhamba kwesikhathi.

Amandla Avelele Omshini

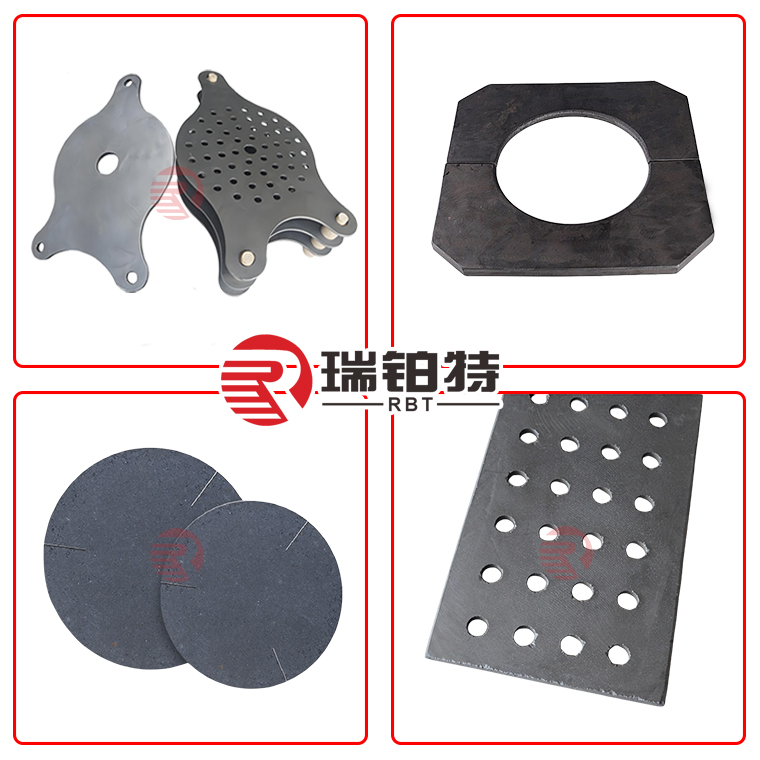

Ngaphezu kwezakhiwo zawo zokuhambisa umoya ezimelana nokushisa nokushisa, amapuleti e-silicon carbide kiln anamandla amangalisayo okusebenza. Amelana kakhulu nokucindezeleka kokusebenza, okuhlanganisa isisindo semithwalo esindayo kanye nomthelela wezinto ezibekwa noma ezisuswa ku-kiln. Lokhu kuqina kuqinisekisa ukuthi amapuleti anempilo ende yesevisi, ngisho nasezindaweni zezimboni lapho angase asetshenziswe khona njalo futhi aphathwe khona. Amandla aphezulu okusebenza e-silicon carbide enza kube nokwenzeka ukuklama amapuleti e-kiln amancane nalula ngaphandle kokulahlekelwa ukusebenza kahle, okungaba wusizo ekwenzeni ngcono isikhala se-kiln nokunciphisa isisindo semishini iyonke.

Ukumelana Okuhle Kakhulu Kwamakhemikhali

Izinqubo ze-oven yezimboni zivame ukuhilela ukuchayeka kumakhemikhali ahlukahlukene, amagesi, nezinto ezibolayo. Amapuleti e-oven ye-silicon carbide anikeza ukumelana okuhle kwamakhemikhali, okwenza afaneleke ukusetshenziswa ezindaweni lapho izinto zendabuko zingase zibole noma zonakale ngokuhamba kwesikhathi. Kungakhathaliseki ukuthi yizimo ze-acidic noma ze-alkaline ezivame ukutholakala ezinqubweni ezithile zokudubula noma ukuba khona kwamagesi asabelayo ekusetshenzisweni kokuncibilika kwensimbi, amapuleti e-oven ye-silicon carbide angamelana nalezi zinselele zamakhemikhali ngaphandle kokulahlekelwa ubuqotho bawo. Lokhu kumelana kwamakhemikhali akugcini nje ngokwandisa isikhathi sokuphila kwamapuleti e-oven kodwa futhi kusiza ukugcina indawo ye-oven ehlanzekile nengenangcolisi, ebalulekile ekukhiqizeni imikhiqizo esezingeni eliphezulu.

Izinhlelo Zokusebenza Ezihlukahlukene

Izakhiwo eziyingqayizivele zamapuleti esitofini se-silicon carbide ziwenza afaneleke kakhulu ezinhlotsheni eziningi zezicelo emikhakheni eminingi. Embonini ye-ceramics, asetshenziswa kabanzi njengamapuleti okusekela okushisa i-porcelain ethambile, izitsha zobumba, kanye namathayela e-ceramic. Ukuqina kwezinga lokushisa eliphezulu kanye nokusatshalaliswa kokushisa okufanayo okunikezwa amapuleti e-silicon carbide kuqinisekisa ukuthi imikhiqizo ye-ceramic ishiswa ngokulinganayo, okuholela emibala ehambisanayo, ukuthungwa, kanye nokuphela kwe-glaze.

Embonini yezinsimbi, amapuleti esitovu se-silicon carbide adlala indima ebalulekile ezinqubweni ezifana nokuncibilikisa insimbi, ukuphonswa, kanye nokwelashwa kokushisa. Angakwazi ukumelana nokushisa okukhulu kanye nesimo sokugqwala kwezinsimbi ezincibilikisiwe, okuhlinzeka ngendawo ethembekile yokubamba nokucubungula izinto zensimbi. Ngaphezu kwalokho, embonini ye-elekthronikhi, amapuleti esitovu se-silicon carbide asetshenziswa ekukhiqizweni kwama-semiconductors nezinye izingxenye ze-elekthronikhi, lapho ukulawulwa kokushisa okunembile kanye nendawo yokushisa ehlanzekile kubalulekile.

Ukukhetha Amapuleti E-Silicon Carbide Kiln Afanele

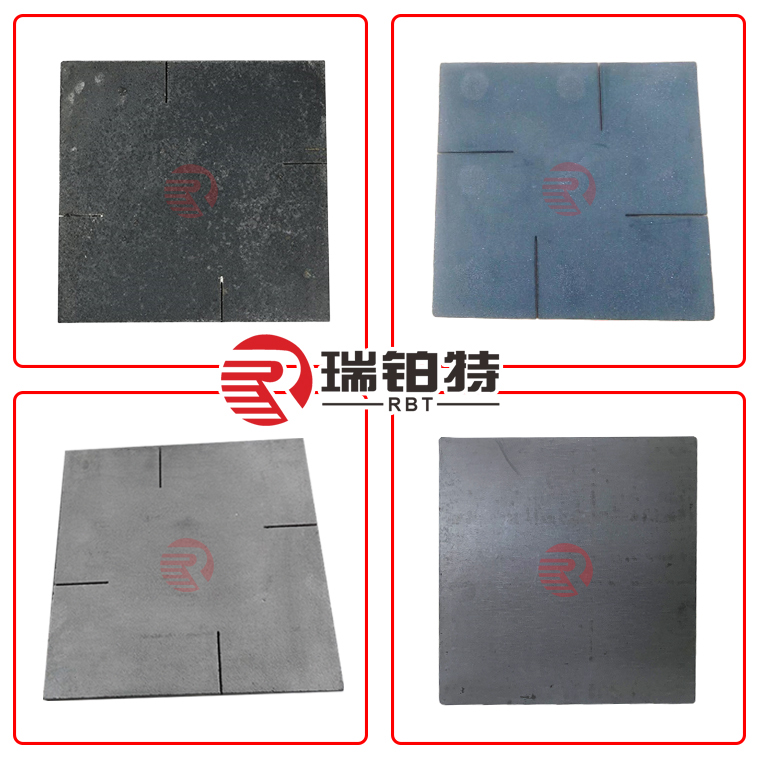

Uma ukhetha amapuleti esitovu se-silicon carbide okusetshenziswa kwakho okukhethekile, kubalulekile ukucabangela izici eziningana. Okokuqala, udinga ukunquma izidingo zokushisa eziphezulu zenqubo yakho yesitovu. Amazinga ahlukene e-silicon carbide ayatholakala, ngalinye linobubanzi balo bokubekezelela amazinga okushisa, ngakho-ke ukukhetha ibanga elifanele kubalulekile ukuqinisekisa ukusebenza kahle.

Kufanele futhi ucabangele ubukhulu kanye nesimo samapuleti esithando. Kudingeka alingane kahle nobukhulu besithando sakho ukuqinisekisa ukusatshalaliswa kokushisa okufanele kanye nokusebenza kahle. Ngaphezu kwalokho, izici ezifana nokuphela kobuso bamapuleti, ukuvuleka kwawo, kanye nokuhambisana kwawo nezinto ezicutshungulwa esithandweni kufanele kucatshangelwe.

Ekuphetheni, amapuleti e-silicon carbide kiln anikeza izinzuzo eziningi ezingathuthukisa kakhulu ukusebenza kanye nokukhiqiza kwemisebenzi yakho ye-kiln. Ngokumelana kwawo nokushisa okumangalisayo, ukuhanjiswa kokushisa okuphezulu, amandla amangalisayo omshini, kanye nokumelana okuhle kwamakhemikhali, la mapuleti ayisisombululo esithembekile nesiguquguqukayo sezinhlobo eziningi zezicelo zezimboni ezishisa kakhulu. Ngokukhetha amapuleti e-silicon carbide kiln afanele izidingo zakho kanye nokusebenza nomhlinzeki othembekile, ungavula amandla aphelele e-kiln yakho futhi uhambise izinqubo zakho zezimboni ezingeni elilandelayo.

Isikhathi sokuthunyelwe: Julayi-07-2025