Isitini se-Magnesia-chromeiyinto eyisisekelo yokungaguquguquki ene-magnesium oxide (MgO) kanye ne-chromium trioxide (Cr2O3) njengezingxenye eziyinhloko. Inezakhiwo ezinhle kakhulu njengokungaguquguquki okuphezulu, ukumelana nokushaqeka kokushisa, ukumelana nokugqwala kanye nokumelana nokuguguleka. Izingxenye zayo eziyinhloko zamaminerali yi-periclase kanye ne-spinel. Lezi zici zenza izitini ze-magnesia-chrome zisebenze kahle ezindaweni ezishisa kakhulu futhi zifanele imishini ehlukahlukene yezimboni eshisa kakhulu.

Izithako kanye nenqubo yokukhiqiza

Izinto zokusetshenziswa eziyinhloko zezitini ze-magnesia-chrome yi-sintered magnesia kanye ne-chromite. I-Magnesia inesidingo sokuhlanzeka okuphezulu, kuyilapho ukwakheka kwamakhemikhali kwe-chromite kuvame ukuba okuqukethwe yi-Cr2O3 phakathi kuka-30% no-45%, kanti okuqukethwe yi-CaO akudluli ku-1.0% kuya ku-1.5%. Inqubo yokukhiqiza ifaka indlela yokubopha ngqo kanye nendlela yokungadubuli. Izitini ze-magnesia-chrome zokubopha ngqo zisebenzisa izinto zokusetshenziswa ezihlanzekile kakhulu futhi zishiswa ekushiseni okuphezulu ukuze zakhe ukubopha ngqo kwesigaba sokushisa okuphezulu kwe-periclase kanye ne-spinel, okuthuthukisa kakhulu amandla okushisa aphezulu kanye nokumelana ne-slag.

Izici zokusebenza

Ukumelana okuphezulu:Ukuqina kokungazweli ngokuvamile kungaphezu kuka-2000°C, futhi kungagcina ukuqina okuhle kwesakhiwo lapho izinga lokushisa liphezulu.

Ukumelana nokushaqeka kokushisa:Ngenxa yokwanda okuphansi kokushisa, ingakwazi ukuzivumelanisa nezinguquko ezinkulu ekushiseni.

Ukumelana ne-slag:Imelana kakhulu ne-alkaline slag kanye ne-asidi ethile, futhi ifaneleka kakhulu ezindaweni ezivezwe yi-slag eshisa kakhulu.

Ukumelana nokugqwala:Iyakwazi ukumelana kakhulu nokuguguleka okushintshana kwe-acid-base kanye nokuguguleka kwegesi.

Ukuqina kwamakhemikhali:Isixazululo esiqinile esakhiwe yi-magnesium oxide kanye ne-chromium oxide ezitini ze-magnesia-chrome sinokuqina okuphezulu kwamakhemikhali.

Izinkambu zohlelo lokusebenza

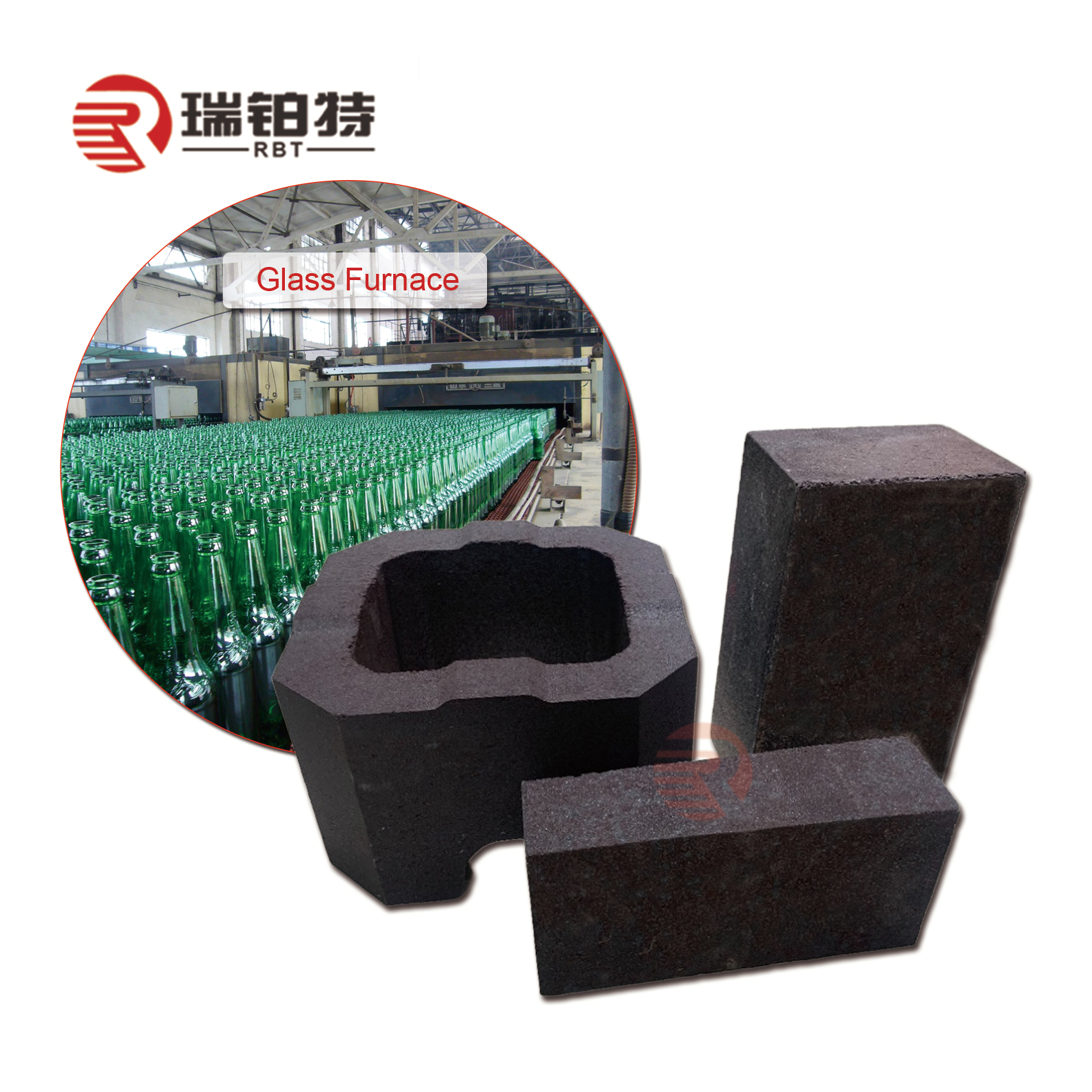

Izitini ze-magnesium-chrome zisetshenziswa kabanzi emikhakheni yezimboni zensimbi, imboni yesamente kanye nemboni yengilazi:

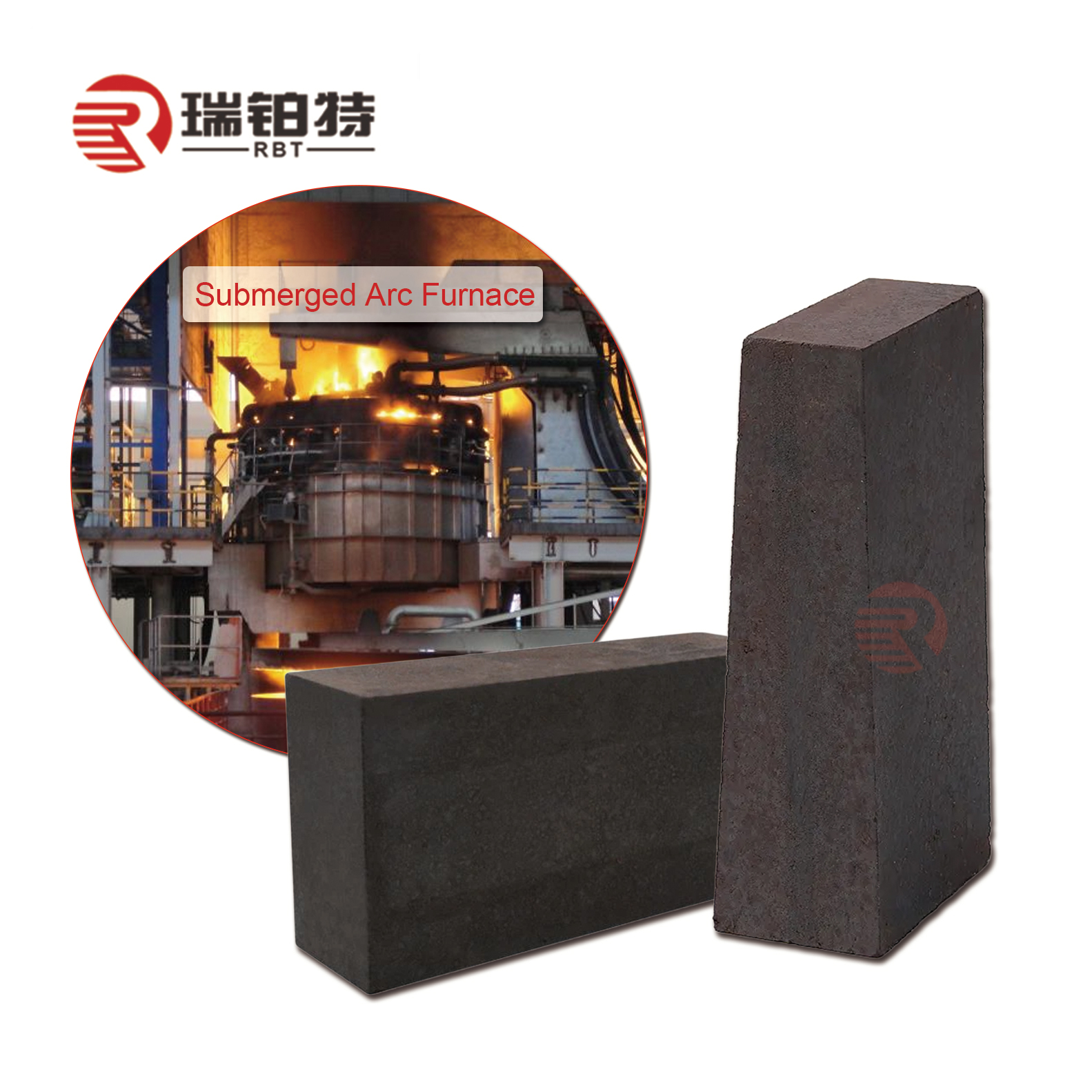

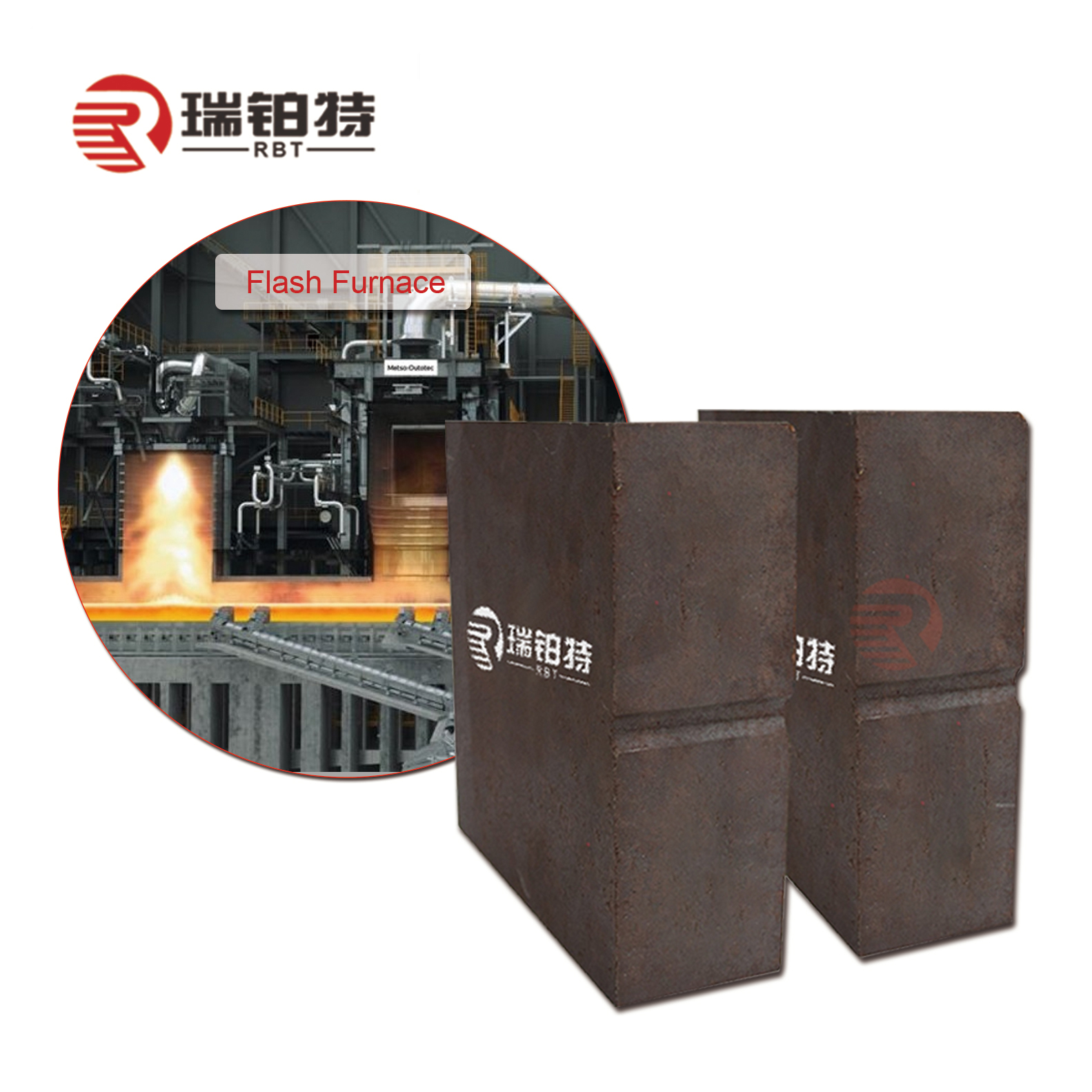

Imboni ye-Metallurgical:Isetshenziselwa ukwakheka kwemishini yokushisa okuphezulu njengeziguquli, izitofu zikagesi ze-arc, izitofu ezivulekile, ama-ladle kanye nezitofu zokuqhuma embonini yensimbi, ezifanele kakhulu indawo yokuphatha i-alkaline slag yokushisa okuphezulu.

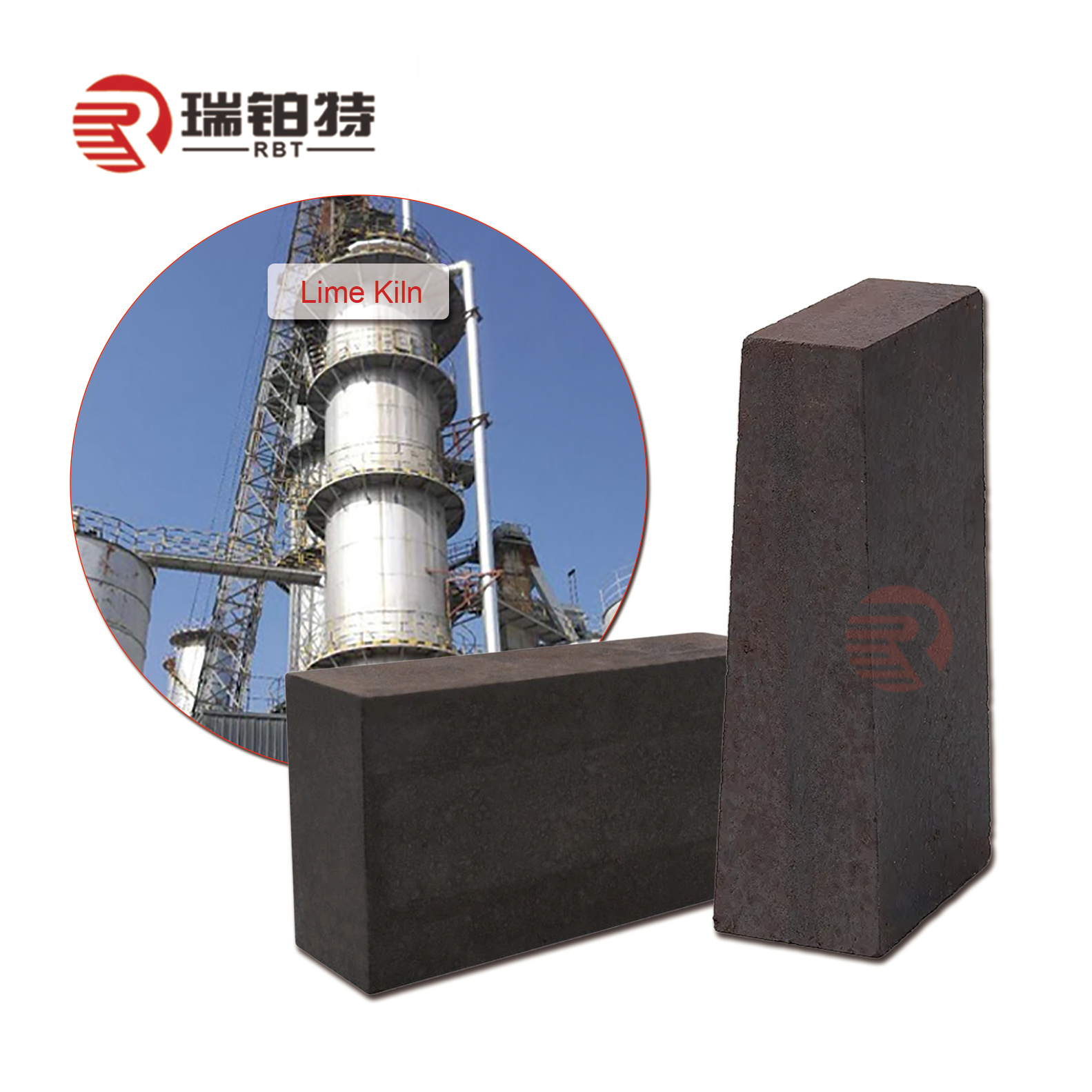

Imboni yesamente:isetshenziselwa indawo yokudubula kanye nendawo yokuguquka kwama-oven ajikelezayo esimende ukuze imelane nokuguguleka kokushisa okuphezulu kanye nomoya we-alkaline.

Imboni yeglasi:isetshenziselwa ukuvuselela kanye nezingxenye zesakhiwo esingaphezulu ezithandweni zokuncibilikisa ingilazi, futhi ingamelana nokuguguleka komkhathi wokushisa okuphezulu kanye noketshezi lwengilazi ye-alkaline.

Isikhathi sokuthunyelwe: Jan-23-2025