I-Silicon Carbide Dryer Lgniter

Izigaba Zomkhiqizo

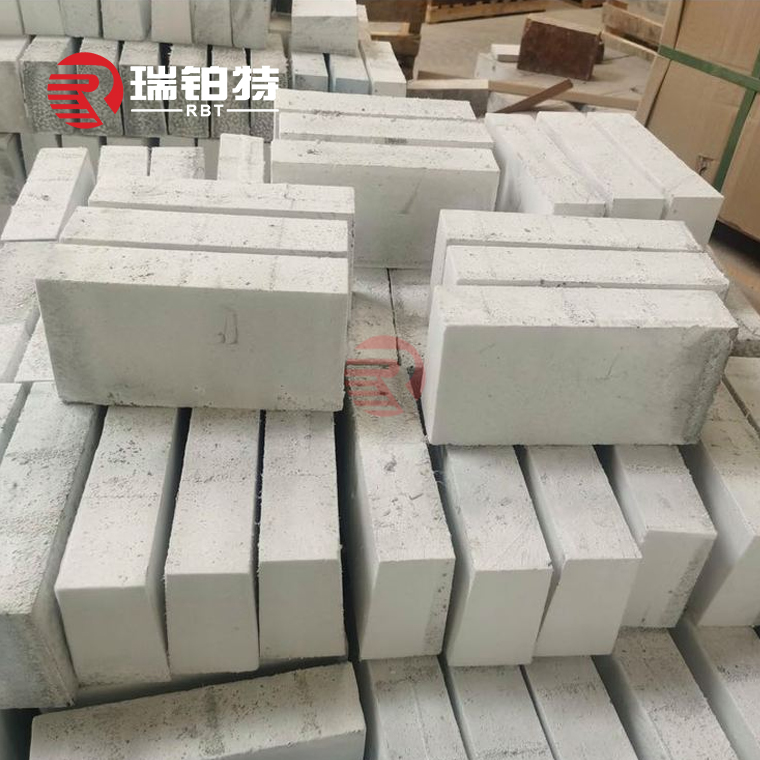

1. Imikhiqizo ye-Reaction sintered silicon carbide(Imikhiqizo ye-RBSiC)

I-Reaction bonded silicon carbide (RBSiC) iyinto ethuthukisiwe yobunjiniyela be-ceramic eyenza isigaba se-silicon carbide bonding ngokusabela ikhabhoni yamahhala ne-silicon ewuketshezi ngaphansi kwezimo zokushisa eziphezulu. Izingxenye zayo eziyisisekelo zifaka i-silicon carbide (SiC) matrix kanye ne-silicon yamahhala (Si). Owokuqala unikeza izakhiwo ezinhle kakhulu zemishini, ukumelana nokugqoka kanye nokuzinza kwezinga lokushisa eliphezulu,

ngenkathi yokugcina igcwalisa ama-pores phakathi kwezinhlayiya ze-silicon carbide ukuthuthukisa ukuminyana nobuqotho besakhiwo sezinto ezibonakalayo.

(1) Izici:

Ukuzinza kwezinga lokushisa eliphezulu:Izinga lokushisa eliphezulu lokusebenza 1350 ℃.

Ukumelana nokugqwala nokumelana nokugqwala:Ifanele izimo zokusebenza ezinzima zokushisa okuphezulu, i-asidi, i-alkali nensimbi encibilikisiwe. .

I-thermal conductivity ephezulu kanye ne-coefficient ephansi yokwanda kwe-thermal:I-thermal conductivity iphezulu njengokungu-120-200 W/(m·K), futhi i-coefficient yokunweba okushisayo ingu-4.5×10⁻⁶ K⁻¹ kuphela, okuvimbela ngempumelelo ukuqhekeka okushisayo nokukhathala okushisayo. .

I-Anti-oxidation:Ungqimba oluqinile lwe-silica oluvikelayo lukhiqizwa phezulu ezingeni lokushisa eliphezulu ukuze lunwebe impilo yesevisi.

(2) Imikhiqizo Eyinhloko:

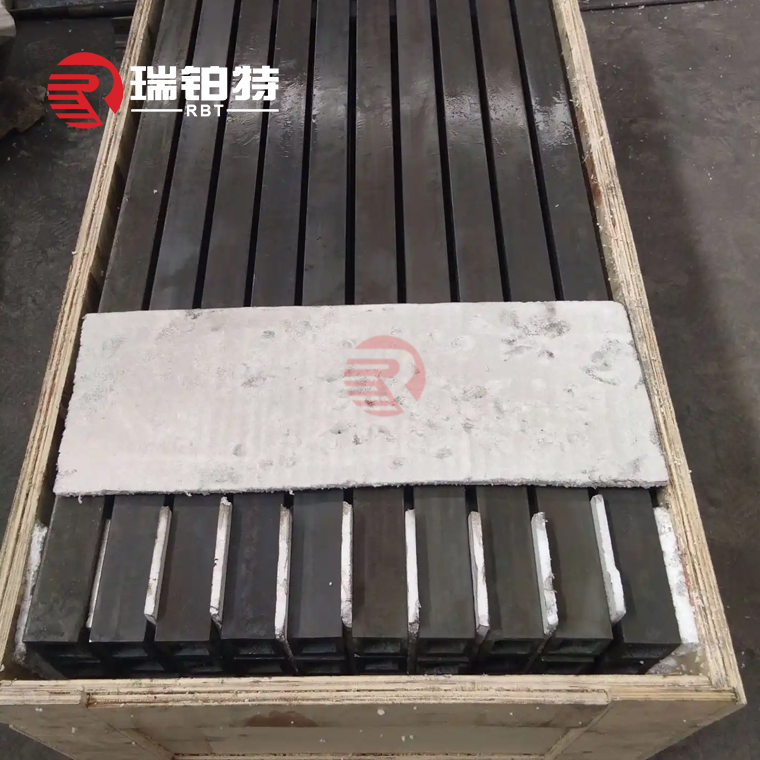

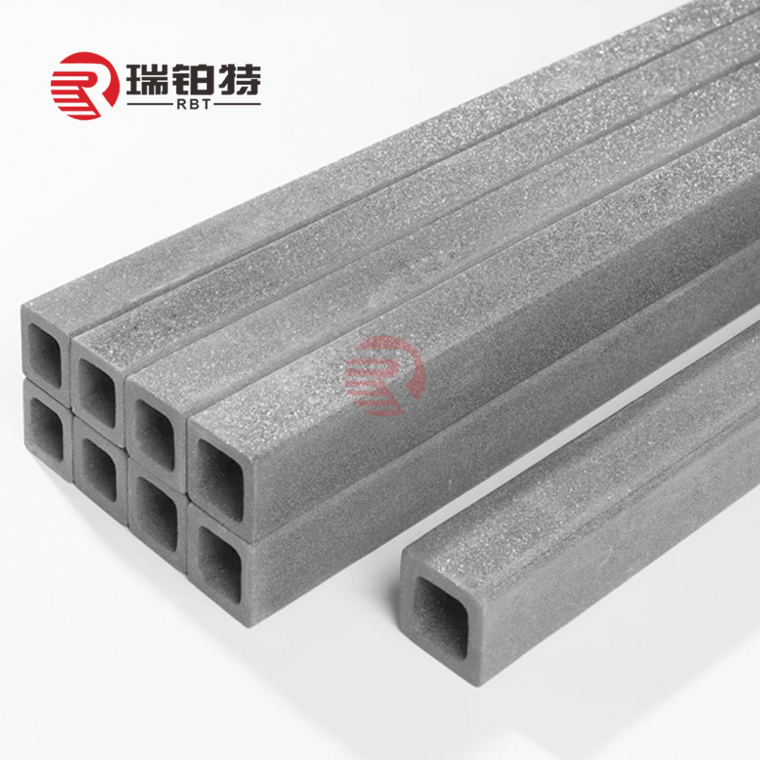

.I-silicon carbide beam:esetshenziselwa isakhiwo esithwala imithwalo semihubhe, izishishi zeshuttle nezinye izihibe zezimboni, ezinokumelana okuhle kakhulu nokushisa okuphezulu.

.

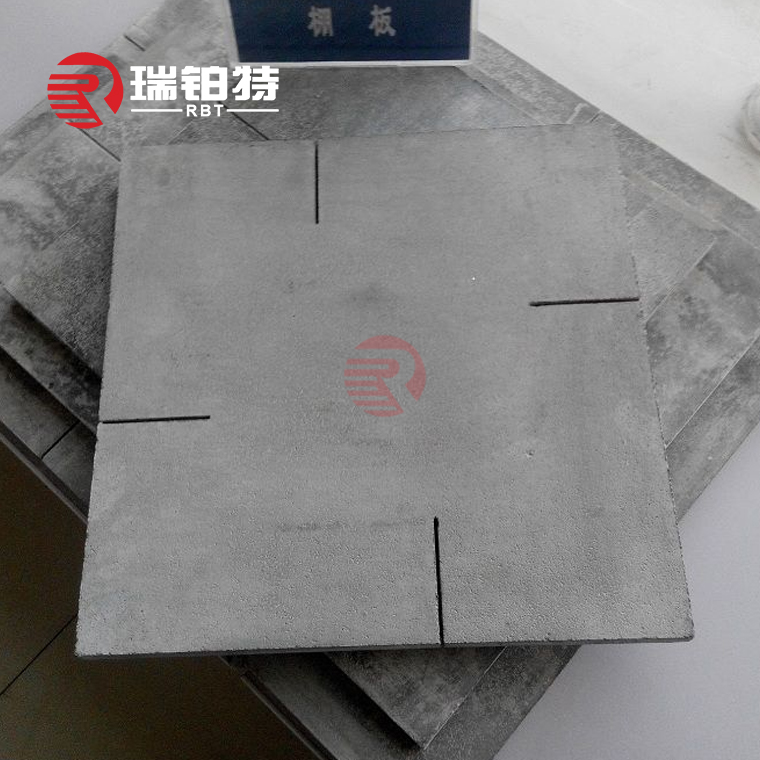

I-Silicon carbide plate:esetshenziselwa izinto eziphikisayo kuma-kilns, enezici ze-oxide bonding. .

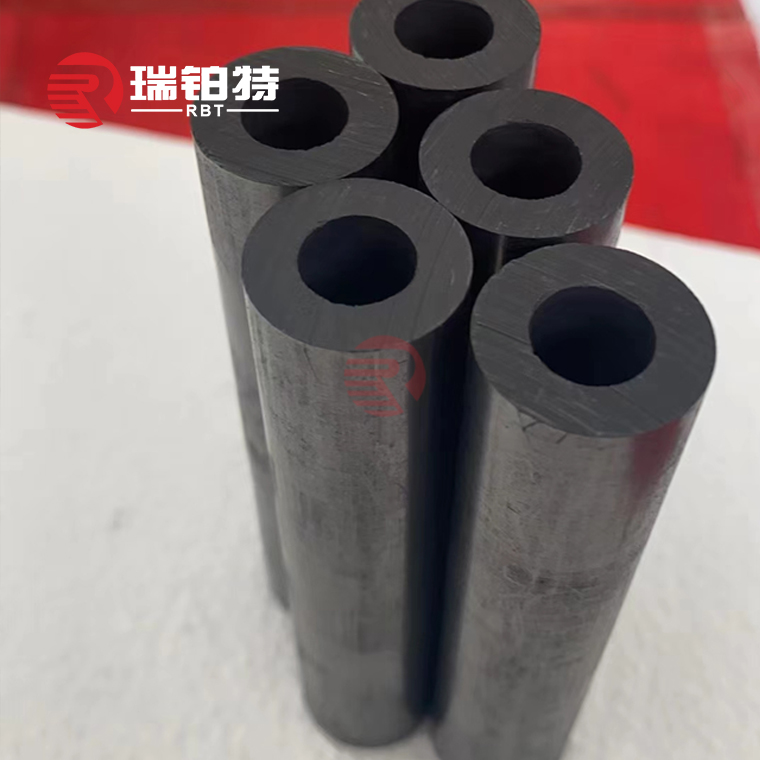

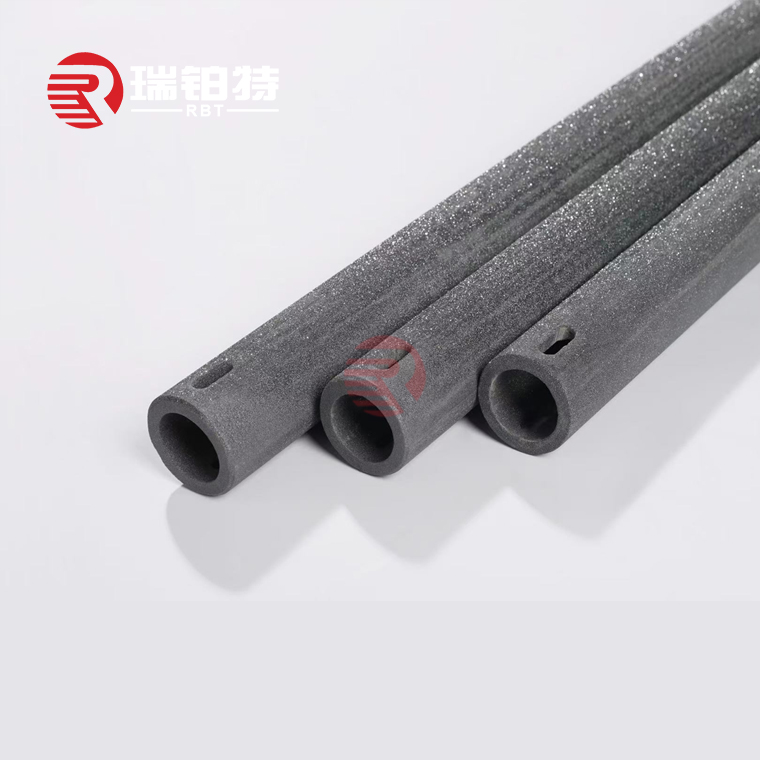

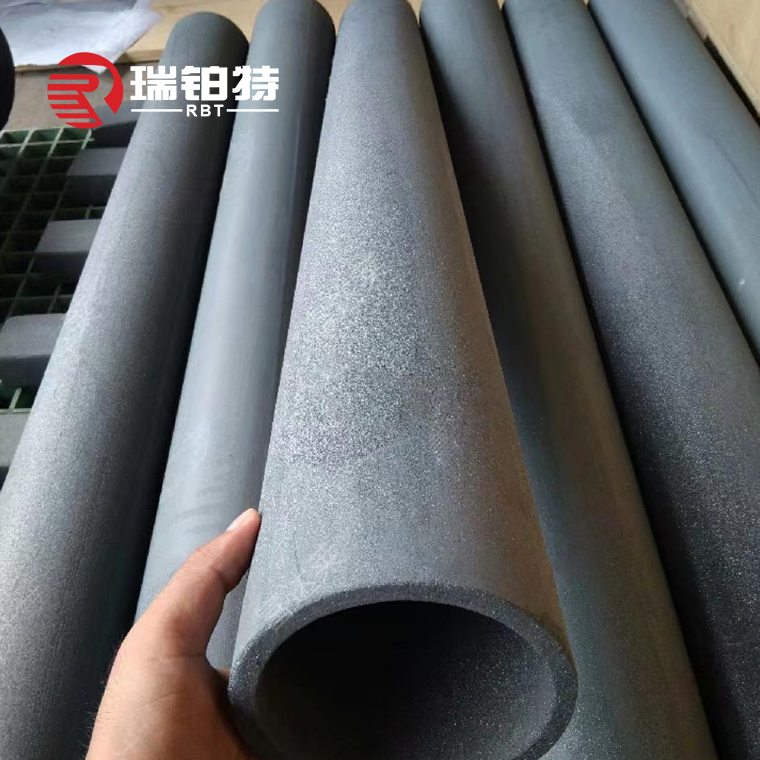

Ipayipi le-silicon carbide:esetshenziselwa amapayipi neziqukathi ezindaweni ezihlukahlukene zokushisa okuphezulu. .

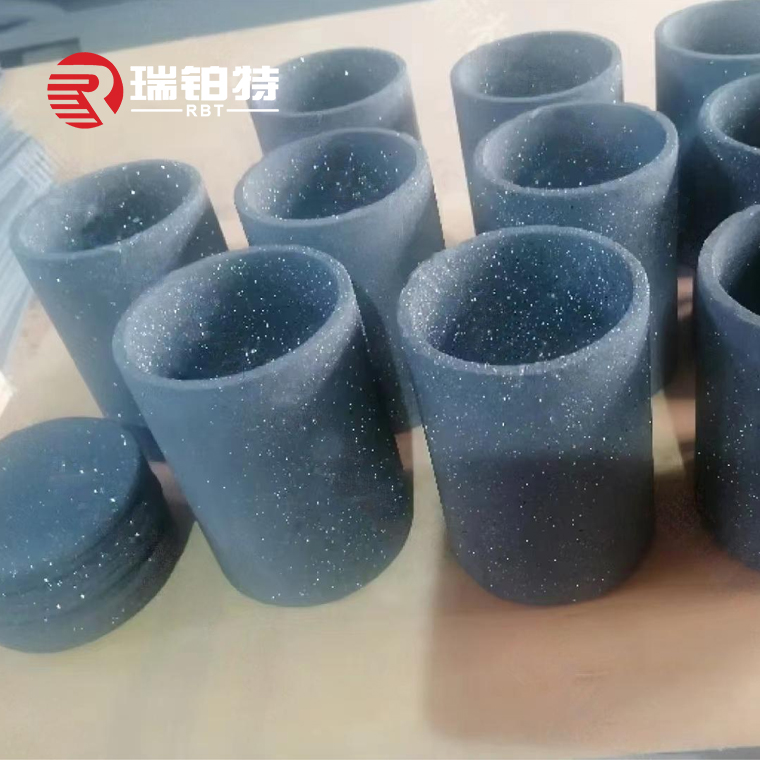

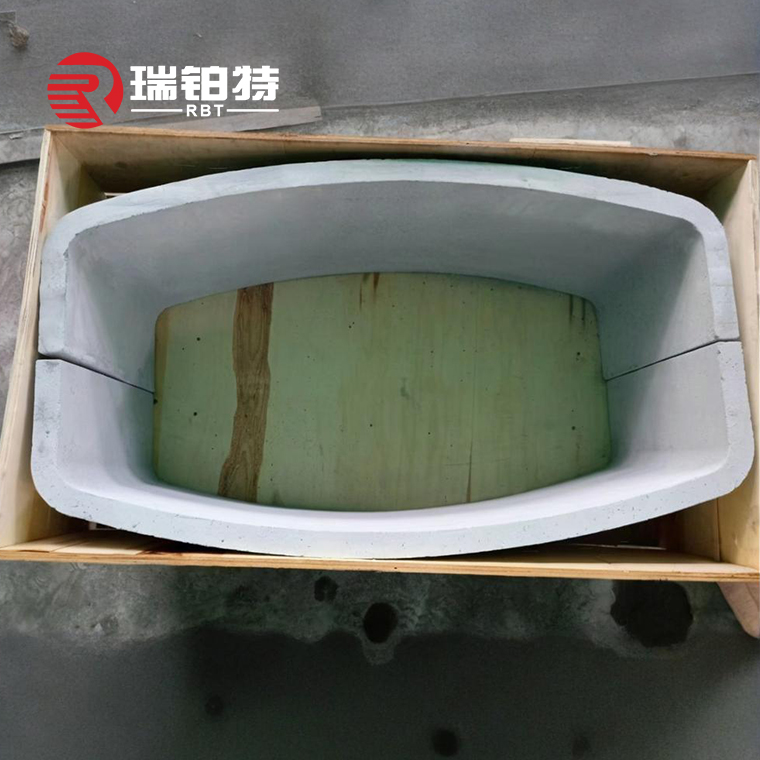

I-silicon carbide crucible kanye ne-sagger:esetshenziselwa ukuncibilikisa izinga lokushisa eliphezulu nokugcinwa kwezinto. .

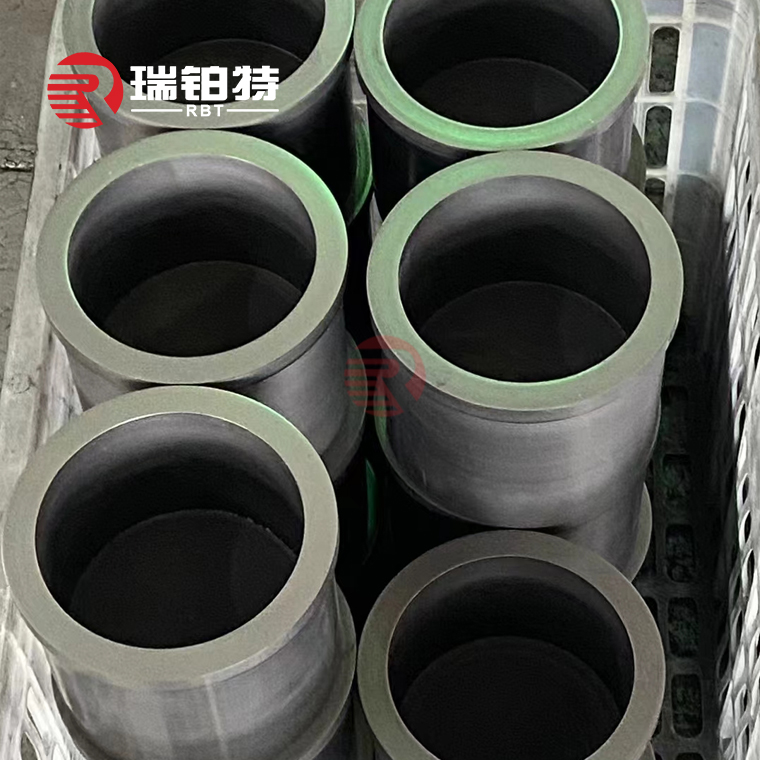

Indandatho ye-silicon carbide seal:isetshenziswa kabanzi emikhakheni yezimoto, i-aerospace kanye nemboni yamakhemikhali, futhi ingagcina ukusebenza okuthembekile kokubeka uphawu ekushiseni okuphezulu nasezindaweni ezinengcindezi ephezulu. .

I-silicon carbide roller:esetshenziselwa izihia zamarola, anezici ze-anti-oxidation, izinga lokushisa eliphezulu lamandla aguquguqukayo kanye nempilo ende yesevisi. .

Amapayipi okupholisa i-silicon carbide:esetshenziselwa indawo yokupholisa yama-roller kilns, enokumelana okuhle nokweqisa

amakhaza nokushisa. .

I-Silicon carbide bunner nozzle:esetshenziselwa uwoyela ohlukahlukene, igesi kanye nezinye izikloni zezimboni, ezinezici zokubanda okukhulu nokumelana nokushisa, ukumelana nokugqoka, ukumelana nokushisa okuphezulu, njll. .

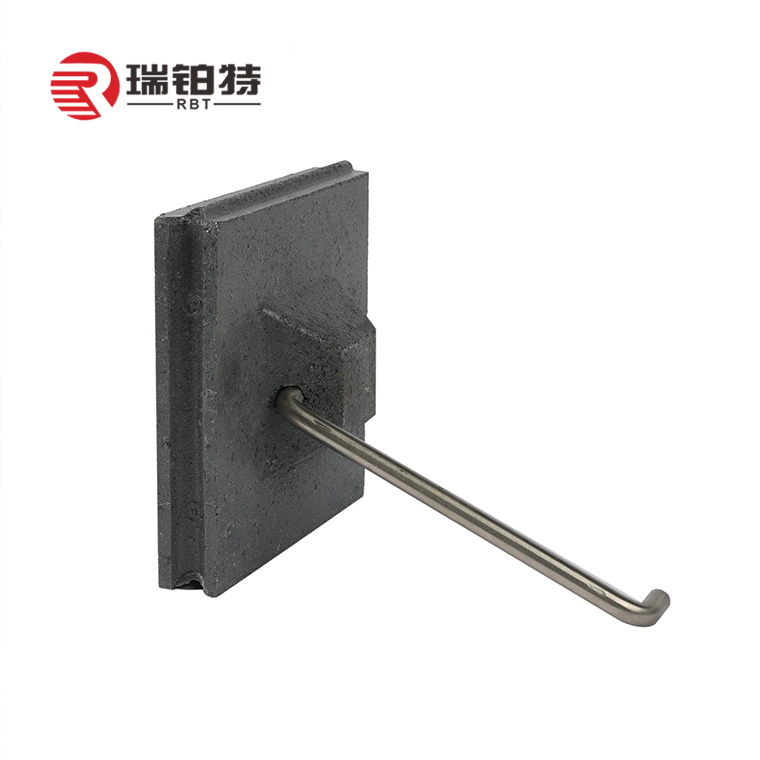

Izingxenye ezenziwe ngokwezifiso ezinomumo okhethekile:Ukukhiqizwa okwenziwe ngokwezifiso kwezingxenye ezihlukahlukene ezimise okukhethekile ngokwezidingo zamakhasimende, njengamapuleti amise okwezinhlanzi, izinduku zokulenga, izingxenye zokusekela, njll.

Imininingwane Izithombe

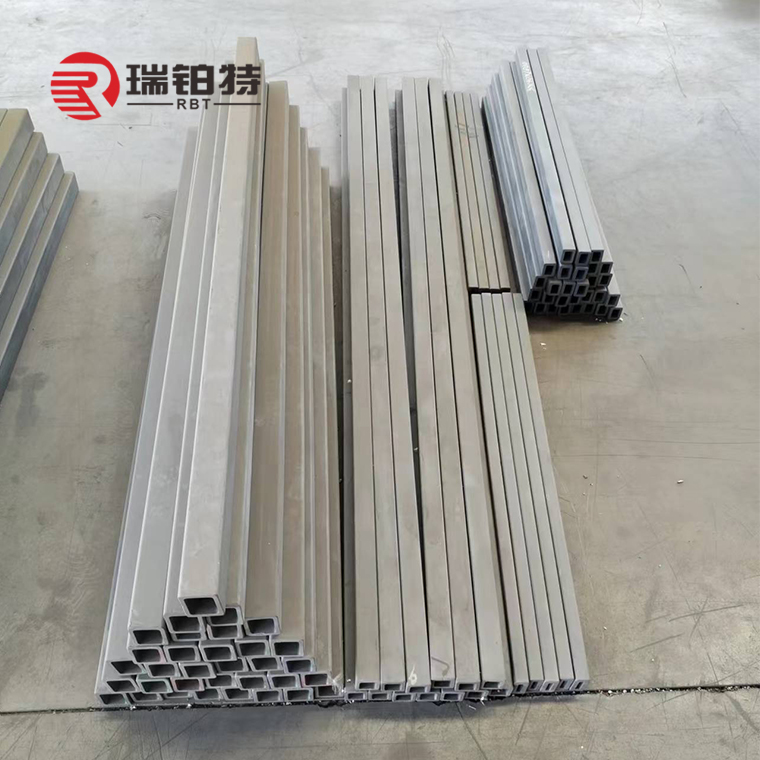

I-Silicon Carbide Beam

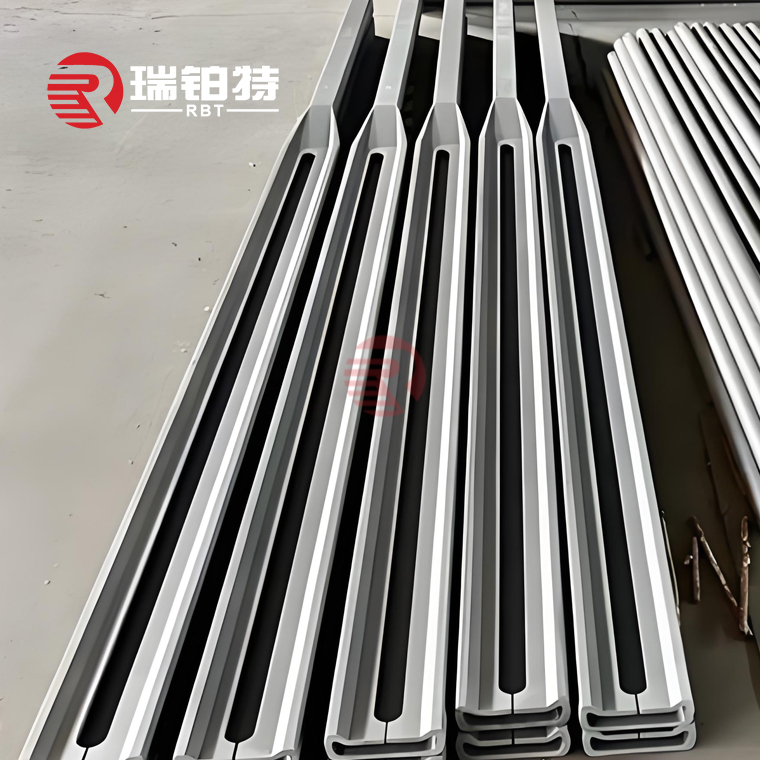

I-Silicon Carbide Cantilever Paddle

I-Silicon Carbide Nozzle

I-Silicon Carbide Burner Tube

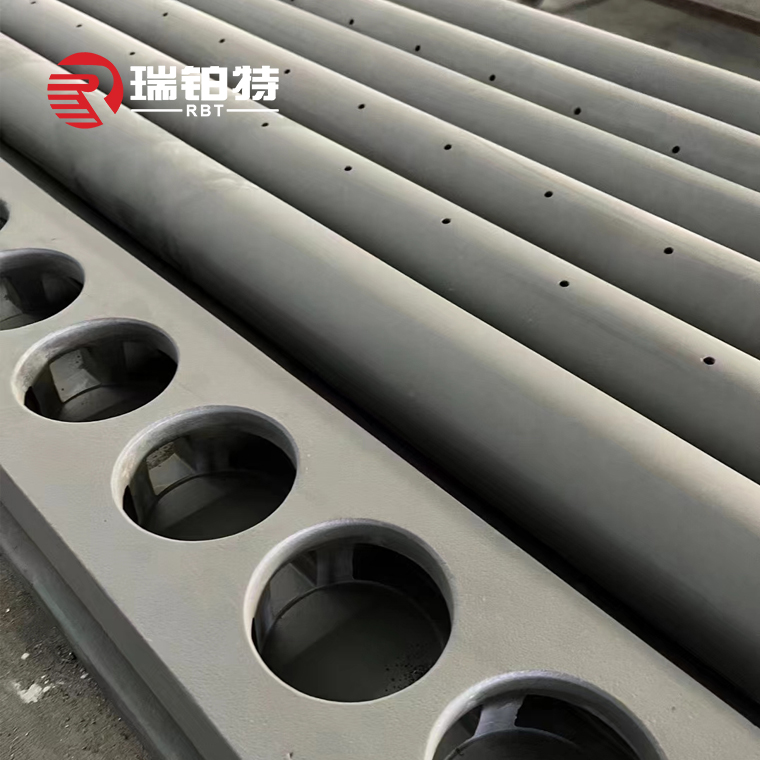

Amapayipi Okupholisa I-Silicon Carbide

I-Silicon Carbide Nozzle

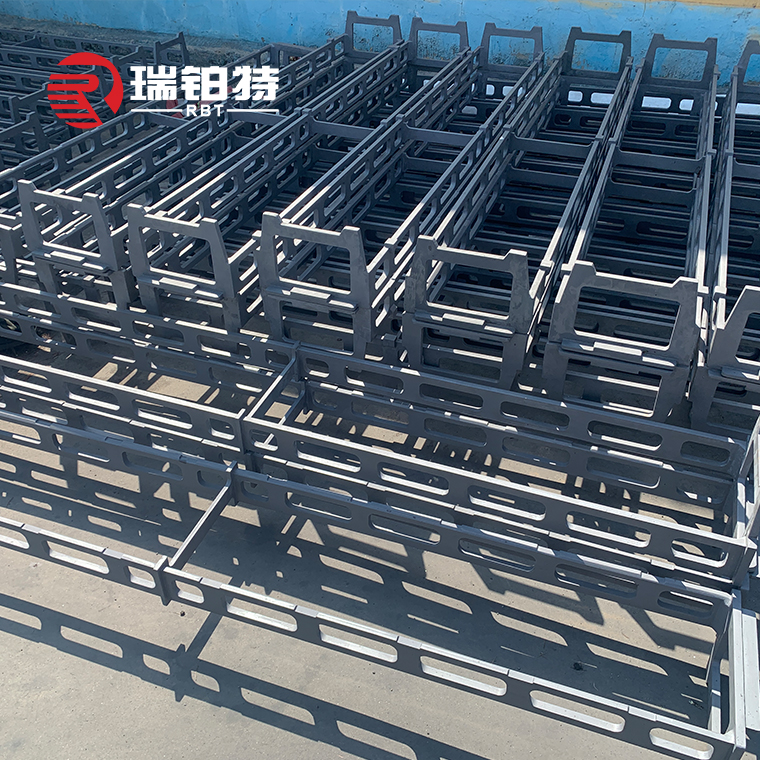

I-Silicon Carbide Boat Bracket

Ulayini Okumelana Nokugqoka

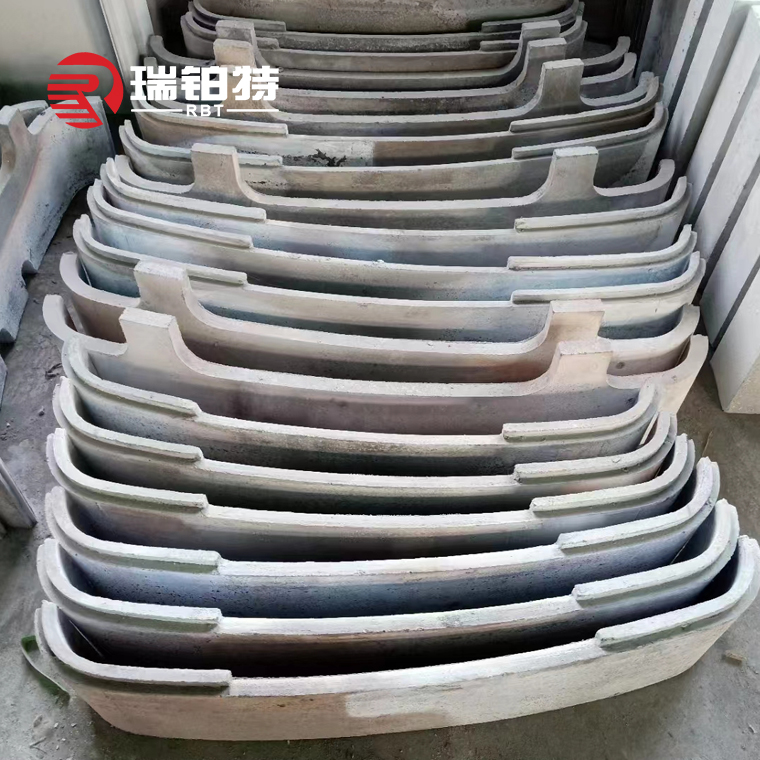

Isikebhe seSilicon Carbide Wafer

Inkomba Yomkhiqizo

| Imikhiqizo ye-RBSiC(SiSiC). | ||

| Into | Iyunithi | Idatha |

| Ubukhulu Bezinga Lokushisa Lokusebenza | ℃ | ≤1350 |

| Ukuminyana | g/cm3 | ≥3.02 |

| Vula i-Porosity | % | ≤0.1 |

| Ukugoba Amandla | Mpa | 250(20℃); 280(1200℃) |

| I-Modulus ye-Elastictiy | I-Gpa | 330(20℃); 300(1200℃) |

| I-Thermal Conductivity | W/mk | 45(1200℃) |

| I-Thermal Expansion Coefficient | K-1*10-6 | 4.5 |

| Ukuqina kukaMoh | | 9.15 |

| I-Acid Alkaline-Ubufakazi | | Kuhle kakhulu |

2. Imikhiqizo ye-silicon carbide engena Pressureless sintered(Imikhiqizo ye-SSiC)

Imikhiqizo ye-silicon carbide engenangcindezi iwuhlobo lwempahla yobumba yobuchwepheshe obuphezulu elungiswe inqubo yokucwilisa engenasici. Ingxenye yayo eyinhloko yi-silicon carbide (SiC), futhi ingxenye ethile yezithasiselo iyengezwa. Ngobuchwepheshe be-ceramic obuthuthukisiwe, yenziwa ibe izitsha ze-ceramic ezingenazimbobo, ezingenamthungo, nezingenangcindezi.

(1) Izici:

Ukumelana nezinga lokushisa eliphezulu:ukusetshenziswa okuvamile ku-1800 ℃;

High thermal conductivity:okulingana ne-thermal conductivity ye-graphiteizinto zokwakha;

Ukuqina okuphezulu:ubulukhuni bungokwesibili kuphela kwedayimane ne-cubic boron nitride;

Ukumelana nokugqwala:i-asidi eqinile ne-alkali enamandla ayinayo ukugqwala kuyo, futhi ukumelana kwayo nokugqwala kungcono kune-tungsten carbide ne-aluminium oxide;

Isisindo esincane:ukuminyana 3.10g/cm3, eduze aluminium;

Akukho deformation:i-coefficient encane kakhulu yokwandisa ukushisa,

Imelana nokushaqeka kwe-thermal:impahla ingamelana noshintsho olusheshayo lokushisa, ukushaqeka okushisayo, ukupholisa okusheshayo nokushisa, futhi inokusebenza okuzinzile.

(2) Imikhiqizo Eyinhloko:

Izindandatho zophawu:Imikhiqizo ye-silicon carbide ene-pressureless sintered ivamise ukusetshenziselwa ukwenza izindandatho zokuvala ezingagugi nezingagqwali namabheringi ashelelayo. .

Izingxenye zemishini:Kubandakanya ama-bearings ashisa kakhulu, izigxivizo zemishini, ama-nozzles, ama-valve omoya, imizimba yephampu, izinto ezilungiswayo, njll.

Imishini yamakhemikhali:Isetshenziselwa ukukhiqiza amapayipi amelana nokugqwala, amathangi okugcina, ama-reactors nama-seal. .

Imishini kagesi:Embonini yamandla, i-silicon carbide engacindezeli isetshenziselwa ukukhiqiza izinto eziphikisa izinga lokushisa eliphezulu, izakhi zokushisa zikagesi kanye nokushintsha kwamandla kagesi aphezulu. .

Ifenisha ye-Kiln:Okufana namafreyimu esakhiwo athwala imithwalo, amarola, amalangabi amalangabi, amapayipi okupholisa, njll. kumahhayela omhubhe, okhini bamashuttle kanye nezinye izihibe zezimboni. .

Imininingwane Izithombe

I-Silicon Carbide Seal Ring

Ipayipi ye-Silicon Carbide

I-Silicon Carbide Liners

I-Silicon Carbide Beam

I-Silicon Carbide Plate

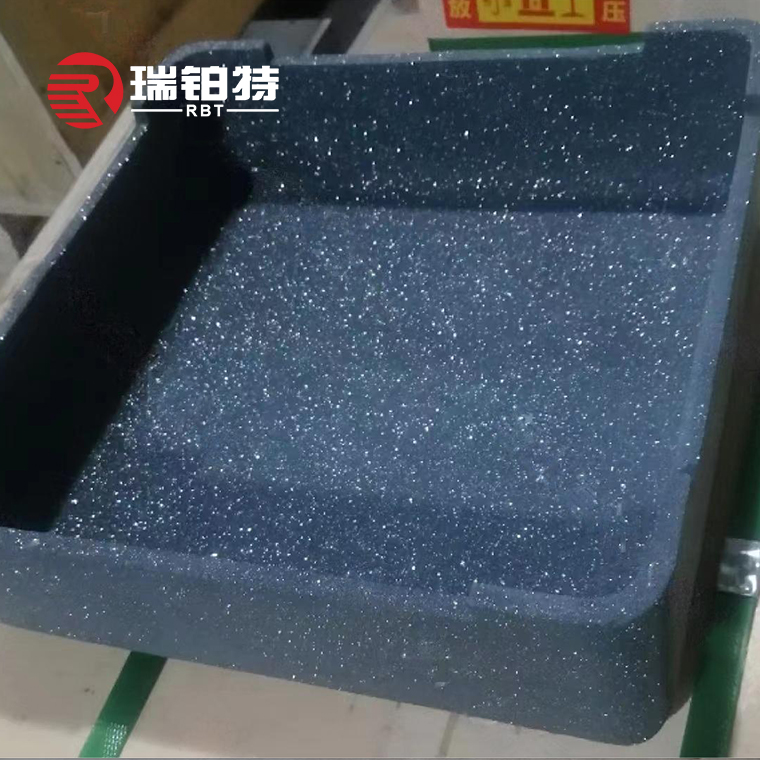

I-Silicon Carbide Yokugaya Umgqomo

Inkomba Yomkhiqizo

| Imikhiqizo ye-SSiC | ||

| Into | Iyunithi | Umphumela |

| Ukuqina | HS | ≥115 |

| I-Porosity Rate | % | <0.2 |

| Ukuminyana | g/cm3 | ≥3.10 |

| Amandla Acindezelayo | Mpa | ≥2500 |

| Ukugoba Amandla | Mpa | ≥380 |

| I-Coefficient of Expansion | 10-6/℃ | 4.2 |

| Okuqukethwe kwe-SiC | % | ≥98 |

| Khulula Si | % | <1 |

| I-Elastic Modulus | I-Gpa | ≥410 |

| Ubukhulu Bezinga Lokushisa Lokusebenza | ℃ | 1400 |

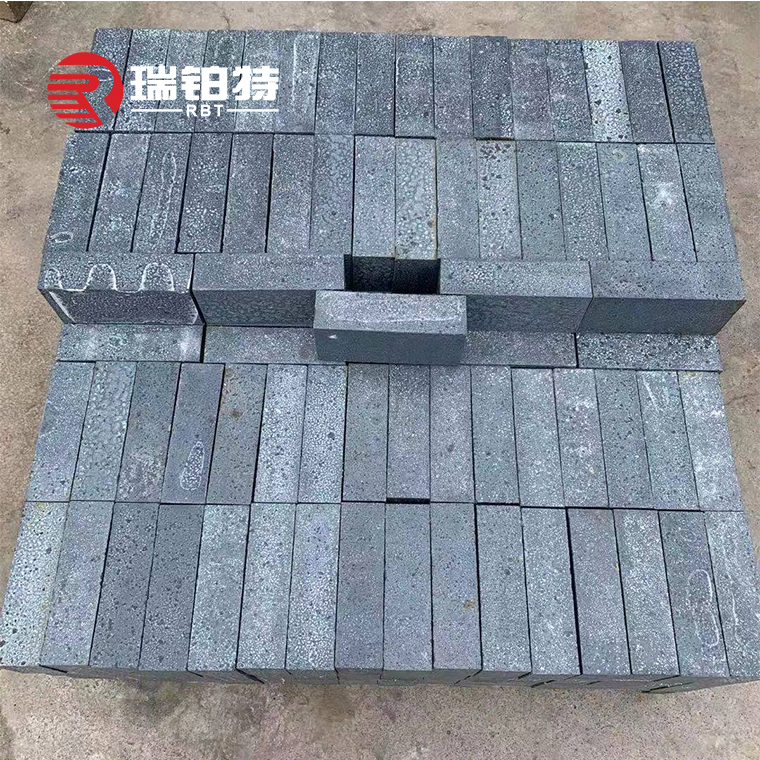

3. Umkhiqizo we-silicon carbide owenziwe kabusha (Imikhiqizo ye-RSiC)

I-Recrystallized Silicon Carbide Products ingumkhiqizo ophikisayo owenziwe nge-high-purity silicon carbide njengempahla eluhlaza. Isici sayo esiyinhloko ukuthi asikho isigaba sesibili futhi sakhiwe i-100% α-SiC.

(1) Izici:

Ukuqina okuphezulu:Ukuqina kwayo kungokwesibili ngemva kwedayimane, futhi inamandla amakhulu kakhulu emishini nokuqina. .

Ukumelana nezinga lokushisa eliphezulu:Ingakwazi ukugcina ukusebenza okuzinzile endaweni yokushisa ephezulu futhi ifanele izinga lokushisa elingu-1350 ~ 1600℃. .

Ukumelana nokugqwala okuqinile:Inokumelana nokugqwala okuphezulu emithonjeni ehlukahlukene futhi ingagcinaizakhiwo zemishini isikhathi eside ezindaweni ezonakalisayo ezihlukahlukene. .

Ukumelana okuhle kwe-oxidation:Inokumelana okuhle ne-oxidation futhi ingasebenza ngokuzinza emazingeni okushisa aphezulu. .

Ukumelana nokushaqeka okuhle kwe-thermal:Isebenza kahle endaweni enezinguquko ezisheshayo zokushisa futhi ifanele izindawo ezishisayo ezishisayo. .

Akukho ukuncipha ngesikhathi sokuhlanza:Ayinciphi ngesikhathi senqubo ye-sintering, futhi akukho ngcindezi eyinsalela ezokhiqizwa ukuze kubangele ukuwohloka noma ukuqhekeka komkhiqizo. Ilungele ukulungiswa kwezingxenye ezinobunjwa obuyinkimbinkimbi nokunemba okuphezulu.

(2) Imikhiqizo Eyinhloko:

Impahla yefenisha ye-Kiln:Ikakhulukazi esetshenziselwa ifenisha yeziko, inezinzuzo zokonga amandla, ukwandisa umthamo osebenzayo weziko, ukunciphisa umjikelezo wokudubula, ukuthuthukisa ukusebenza kahle kokukhiqizwa kweziko kanye nezinzuzo eziphezulu zezomnotho. .

Ama-nozzles we-bunner:Ingasetshenziswa njengamakhanda we-nozzle ovuthayo futhi ifanele izindawo zokushisa eziphezulu. .

Amashubhu okushisa ngemisebe ye-Ceramic:Lawa mashubhu okushisa asebenzisa ukuzinza okuphezulu kwezinga lokushisa kanye nokumelana nokugqwala kwe-silicon carbide eyenziwe kabusha futhi afanele ukusetshenziswa kwezimboni ezihlukahlukene zokushisa okuphezulu. .

Amashubhu okuvikela izingxenye:Ikakhulukazi ezithandweni zomoya, imikhiqizo ye-silicon carbide eyenziwe kabusha isetshenziswa njengamashubhu okuvikela ingxenye enamazinga okushisa aphezulu kanye nokumelana nokugqwala. .

Imizimba yephampu lokushisa eliphezulu, ama-impellers, ama-bearings, izindlu zenjini:Emkhakheni wezimoto, i-aerospace kanye nezimboni zezempi, izinto zokwakha ze-silicon carbide ezenziwe kabusha zenziwa zaba yimizimba yepompo yokushisa ephezulu, ama-impellers, ama-bearings kanye nezindlu zenjini, njll., isebenzisa ukumelana nokushisa okuphezulu, ukumelana nokugqwala kwe-asidi kanye ne-alkali kanye nokumelana nokugqoka. .

Imininingwane Izithombe

Izingxenye ezibunjiwe ze-Silicon Carbide

I-Silicon Carbide Plate

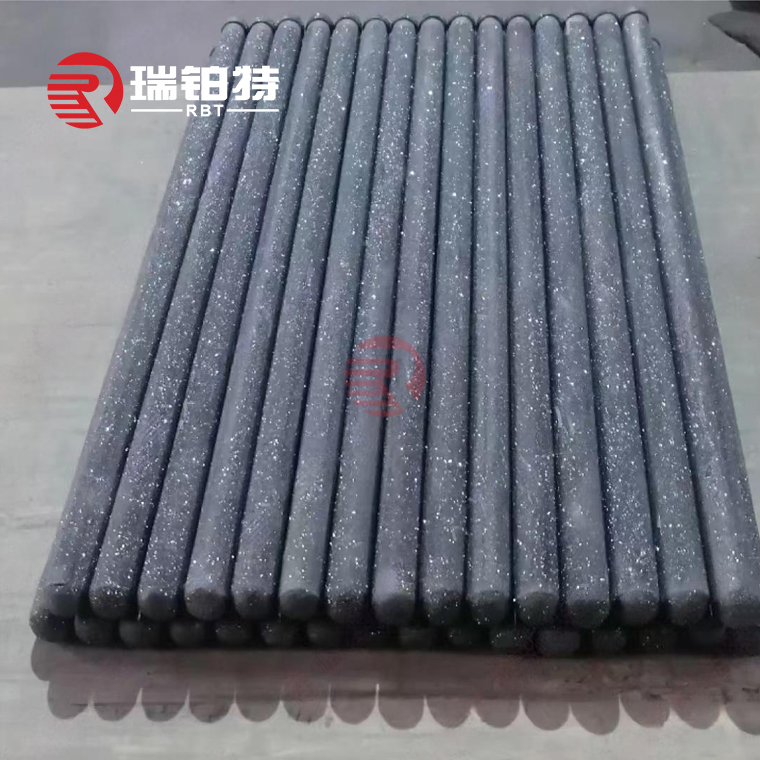

I-Silicon Carbide Roller

I-Silicon Carbide Beam

I-Silicon Carbide Protection Tubes

I-Kiln Furniture

I-Silicon Carbide Sagger

I-Silicon Carbide Crucible

I-Silicon Carbide Plate

I-Silicon Carbide Lgniter

Ipayipi ye-Silicon Carbide

I-Silicon Carbide Burner

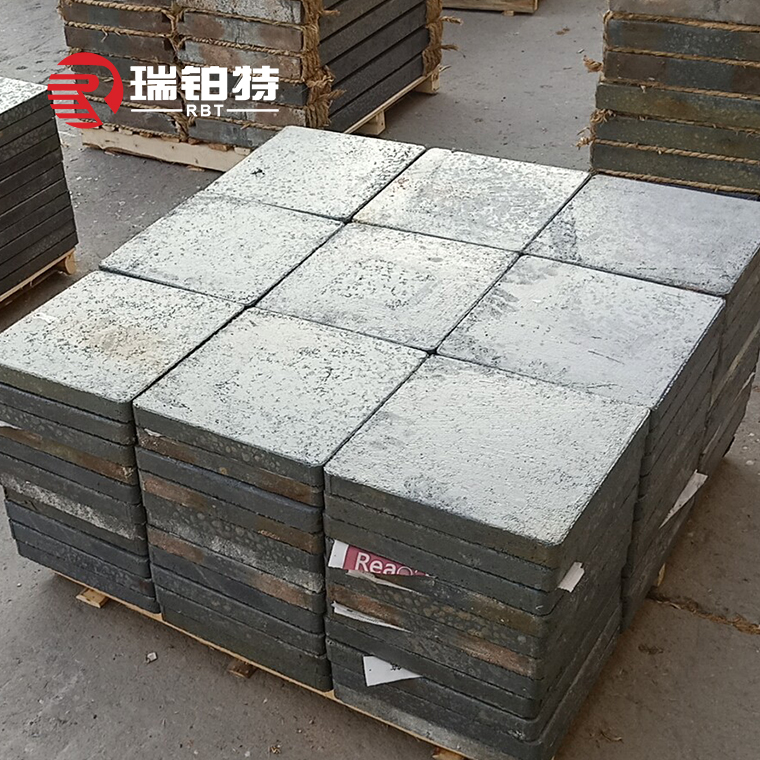

4. Imikhiqizo ye-silicon nitride ehlanganisiwe ye-silicon carbide(Imikhiqizo ye-NSiC)

Imikhiqizo ye-silicon nitride eboshiwe ye-silicon carbide iyimpahla eyakhiwe ngokwengeza i-SiC aggregate ku-silicon powder yezimboni, isabela nge-nitrogen ekushiseni okuphezulu ukuze ikhiqize i-Si3N4 futhi ihlanganiswe ngokuqinile nezinhlayiya ze-SiC.

(1) Izici:

Ukuqina okuphezulu:Ukuqina kwe-Mohs kwemikhiqizo ye-silicon nitride eboshiwe ye-silicon carbide cishe ku-9, okwesibili ngemva kwedayimane, futhi kuyimpahla enobulukhuni obuphakeme phakathi kwezinto ezingezona ezensimbi. .

Amandla okushisa aphezulu:Emazingeni okushisa aphezulu we-1200-1400 ℃, amandla nobulukhuni bezinto ezisetshenziswayo kuhlala kucishe kungashintshiwe, futhi izinga lokushisa eliphakeme lokusebenzisa okuphephile lingafinyelela ku-1650-1750 ℃.

.

Ukuzinza kwe-Thermal:Ine-coefficient encane yokwandisa okushisayo kanye ne-thermal conductivity ephezulu, akulula ukukhiqiza ukucindezelwa kokushisa, inokuqina okuhle kokushiswa kokushisa kanye nokumelana nokukhuphuka, futhi ifanele izindawo ezibandayo kakhulu nezishisayo. .

Ukuzinza kwamakhemikhali:Iyakwazi ukumelana nokugqwala futhi imelana ne-oxidation, futhi ingahlala izinzile ezindaweni ezihlukahlukene zamakhemikhali. .

Ukumelana nokugqoka:Inokumelana nokugqokwa okuhle futhi ifanele ukusetshenziswa kwezimboni ezahlukahlukene ngokuguga okunzima.

(2) Imikhiqizo Eyinhloko:

Izitini eziphikisayo:isetshenziswa kabanzi ku-electrolytic aluminium, insimbi yokwenza iziqhumane, izithando ze-arc ezingaphansi kwamanzi nezinye izimboni, ezinezici zokumelana nokushisa okuphezulu, ukumelana nokugqwala, nokumelana nokuguguleka.

Ifenisha yekhishi:esetshenziselwa amasondo e-ceramic okugaya, i-porcelain kagesi ene-voltage ephezulu, ama-kilns ezimboni, njll., enekhono elihle lokuthwala umthwalo kanye nokumelana nokushisa okuphezulu.

Imikhiqizo emise okukhethekile:esetshenziswa ekubunjweni kwe-metallurgical non-ferrous, amandla ashisayo, ama-arc angaphansi kwamanzi nezinye izimboni, ezinezici zokumelana nokugqoka kanye nokumelana nokushisa okuphezulu.

Izingxenye eziphikisayo:okuhlanganisa amashubhu okuvikela i-thermocouple, amashubhu okukhuphuka, imikhono yokushisa, njll., esetshenziswa kuma-kilns okushisa okuphezulu kanye ne-atmosphere ehlukahlukene, enokushisa okuphezulu kwe-thermal kanye nokumelana nokugqwala.

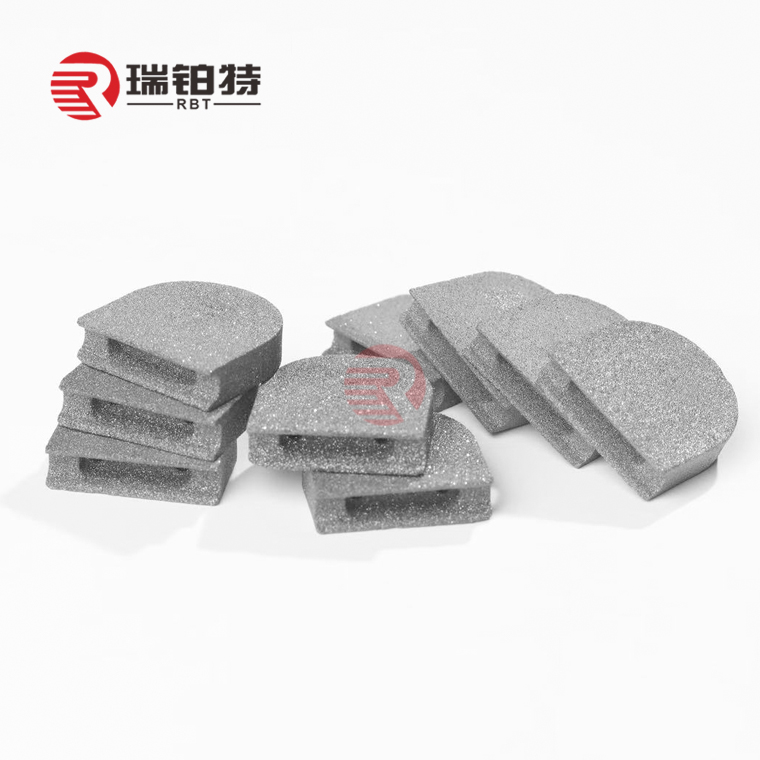

Imininingwane Izithombe

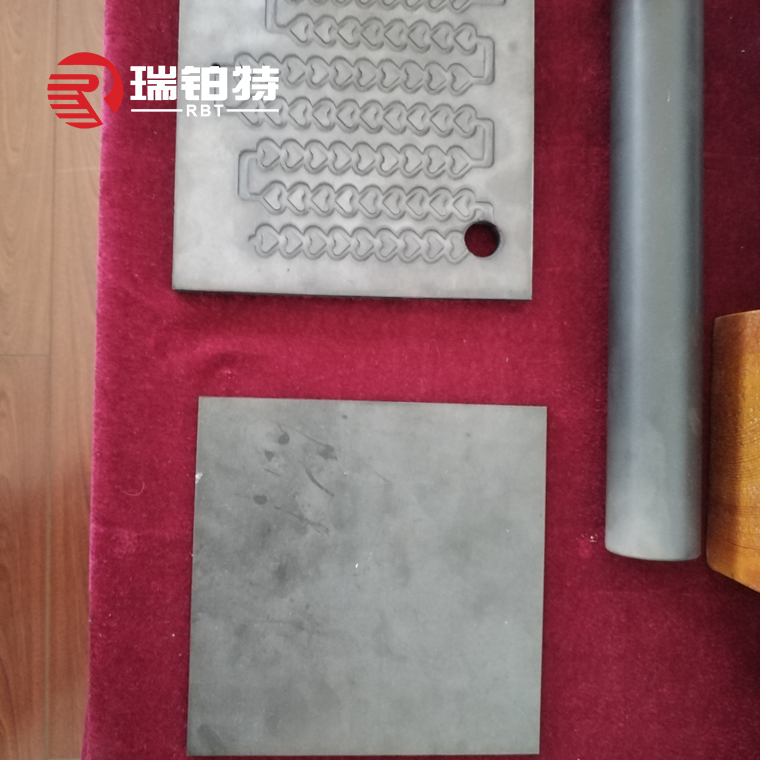

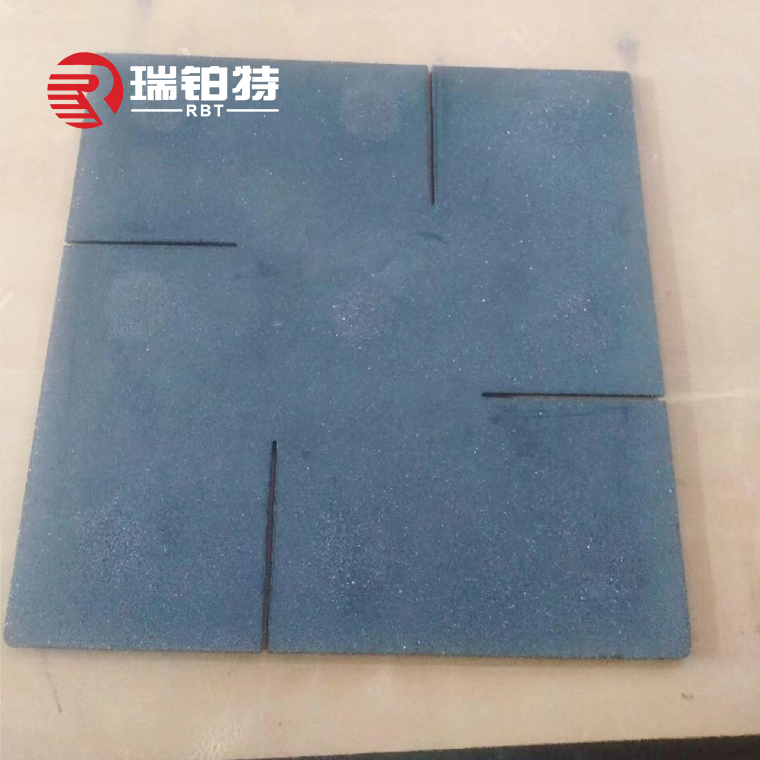

I-Silicon Carbide Shaped Plate

I-Silicon Carbide Shaped Plate

I-Silicon Carbide Shaped Plate

I-Silicon Carbide Shaped Plate

I-Silicon Carbide Shaped Plate

I-Silicon Carbide Radiation Tubes

Ipayipi ye-Silicon Carbide

I-Silicon Carbide Shaped Plate

Izingxenye ezibunjiwe ze-Silicon Carbide

I-Silicon Carbide Protection Tubes

I-Silicon Carbide Plate

Izitini ze-Silicon Carbide

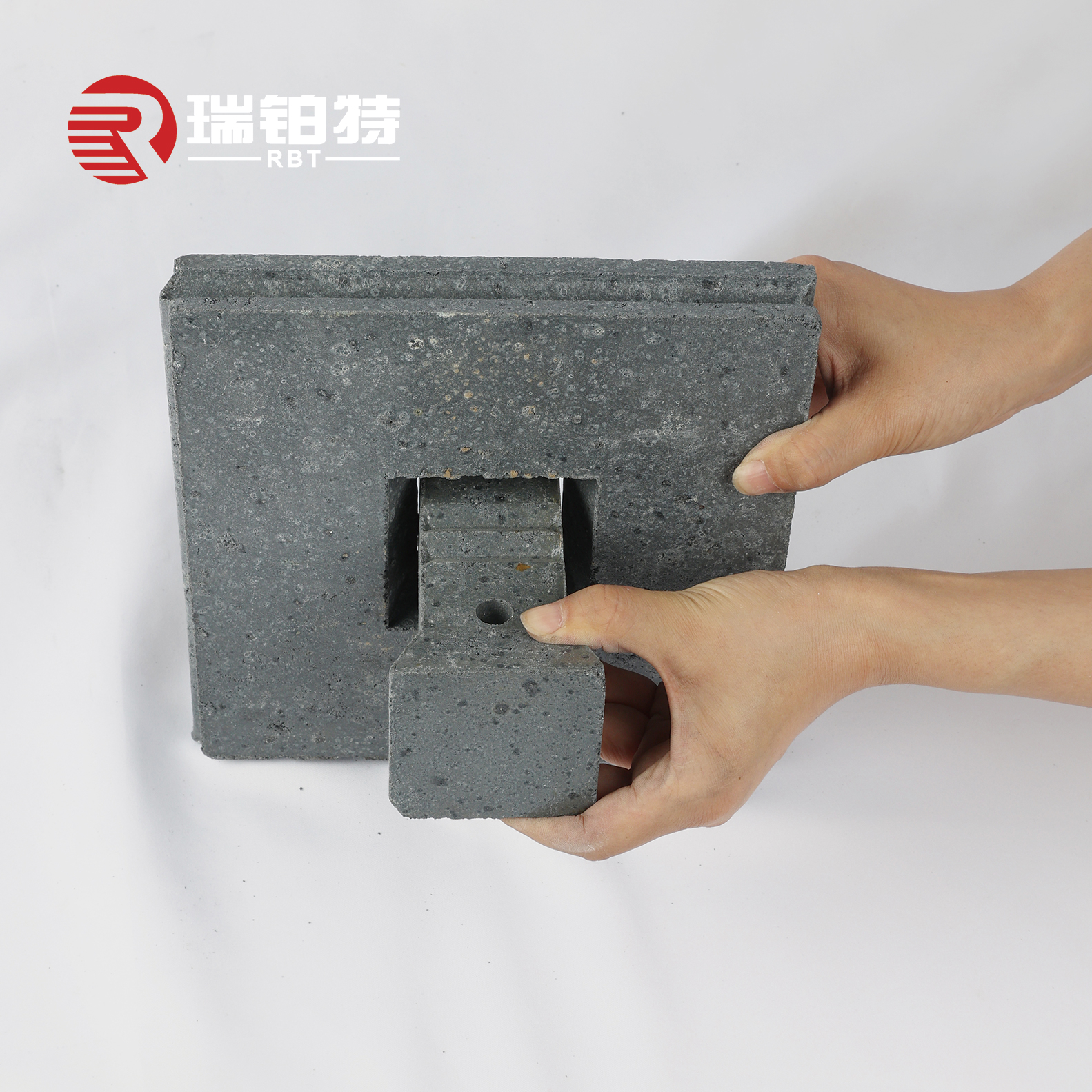

5. Imikhiqizo ye-silicon carbide ene-oksidi

Imikhiqizo ye-silicon carbide ene-oxide yenziwa ngokuxuba izinhlayiya ze-silicon carbide ne-oxide powder (njenge-silicon dioxide noma i-mullite), ukucindezela kanye nokucwilisa ezingeni lokushisa eliphezulu. Isici saso siwukuthi ngesikhathi senqubo ye-sintering kanye nokusetshenziswa, ifilimu ye-oxide isongwe ezinhlayiyeni ze-silicon carbide, ezithuthukisa kakhulu ukumelana ne-oxidation namandla okushisa aphezulu.

Inezici zamandla aphezulu okushisa okuguquguqukayo, ukuzinza okuhle kokushaqeka kokushisa, ukuguquguquka okuphezulu kokushisa, ukumelana nokugqoka kanye nokumelana okuqinile nokuguguleka komkhathi okuhlukahlukene, futhi iyinto ekahle yokonga amandla ezithandweni zezimboni.

(2) Imikhiqizo Eyinhloko:

Imikhiqizo ye-silicon dioxide eboshwe nge-silicon carbide:Lo mkhiqizo usebenzisa i-silicon dioxide (SiO2) njengesigaba sokubopha. Ngokuvamile i-5% ~ 10% ye-silicon dioxide powder noma i-quartz powder ixutshwa nezinhlayiya ze-silicon carbide (SiC). Kwesinye isikhathi kuyengezwa i-flux. Ngemva kokuyicindezela futhi yakhiwe, ishiswa kuhhavini ovamile. Isici salo ukuthi ngesikhathi sokudubula nokusebenzisa, ifilimu ye-silicon dioxide ihlanganiswe ezinhlayiyeni ze-silicon carbide, ezithuthukisa kakhulu ukumelana ne-oxidation namandla okushisa aphezulu. Lo mkhiqizo usetshenziswa kakhulu emashalofini eziko ukuze kuqhunyiswe porcelain (> 1300 ℃), futhi impilo yawo yesevisi ingaphezu

iphindwe kabili kunemikhiqizo ye-silicon carbide eboshwe ngobumba. .

Imikhiqizo ye-silicon carbide ehlanganisiwe ye-Mullite:Lo mkhiqizo wengeza i-α-Al2O3 powder kanye ne-silicon dioxide powder ezithakweni ze-silicon carbide. Ngemuva kokucindezela nokwenza, i-Al2O3 ne-SiO2 zihlanganiswa ukuze zenze i-mullite ngesikhathi senqubo yokucwilisa. Ngesikhathi sokusetshenziswa, i-silicon dioxide eyakhiwe yi-oxidation ye-silicon carbide iyingxenye ye-mullite ne-Al2O3. Le nto inokuqina okuhle kokushaqeka kwe-thermal futhi isetshenziswa kakhulu ekwenzeni ama-saggers we-porcelain namashalofu.

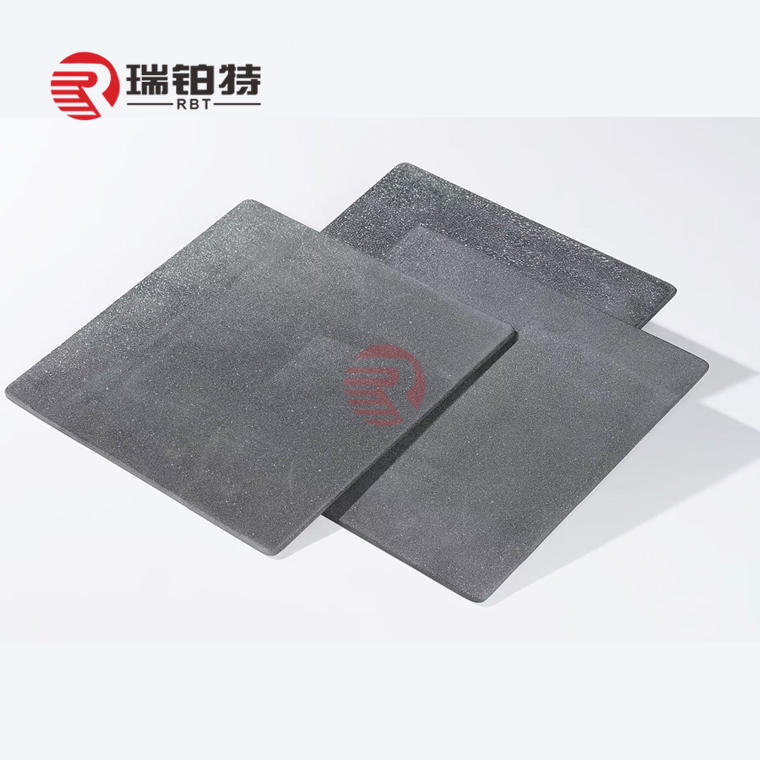

Imininingwane Izithombe

I-Silicon Carbide Plate

Izitini ze-Silicon Carbide

I-Silicon Carbide Plate

Ipayipi le-SiC Microcrystalline

Ibhodi le-SiC Microcrystalline

Ibhodi le-SiC Microcrystalline

Iphrofayela Yenkampani

Inkampani Shandong Robert New Material Co., Ltd.itholakala eZibo City, eSifundazweni saseShandong, eChina, okuyindawo yokukhiqiza impahla ephikisayo. Siyinkampani yesimanje ehlanganisa ucwaningo nentuthuko, ukukhiqiza, ukuthengisa, ukwakhiwa kweziko nokwakha, ubuchwepheshe, kanye nezinto ezikhiqizayo zokuthumela ngaphandle. Sinemishini ephelele, ubuchwepheshe obuphambili, amandla obuchwepheshe aqinile, ikhwalithi yomkhiqizo omuhle kakhulu, kanye nedumela elihle. Ifektri yethu ihlanganisa amahektha angaphezu kuka-200 futhi umphumela wonyaka wezinto eziphikisayo ezinokwakheka cishe amathani angu-30000 futhi izinto eziphikisayo ezingabunjiwe zingamathani ayi-12000.

Imikhiqizo yethu eyinhloko yezinto eziphikisayo ihlanganisa:izinto ze-alkaline refractory; aluminium silicon refractory izinto; izinto eziphikisayo ezingakhiwe; ukufakwa kwe-thermal refractory materials; izinto ezikhethekile zokuphikisa; izinto ezisebenzayo eziphikisayo zamasistimu okusakaza aqhubekayo.

imibuzo ejwayelekile ukubuzwa

Udinga usizo? Qiniseka ukuthi uvakashela izinkundla zethu zokusekela ukuze uthole izimpendulo zemibuzo yakho!

Singumkhiqizi wangempela, imboni yethu ikhethekile ekukhiqizeni izinto eziphikisayo iminyaka engaphezu kwengu-30. Sithembisa ukuhlinzeka ngenani elingcono kakhulu, insizakalo engcono kakhulu yokuthengisa ngaphambilini kanye neyokuthengisa ngemva kokuthengisa.

Ngenqubo ngayinye yokukhiqiza, i-RBT inohlelo oluphelele lwe-QC lokwakheka kwamakhemikhali nezinto ezibonakalayo. Futhi sizohlola izimpahla, futhi isitifiketi sekhwalithi sizothunyelwa nezimpahla. Uma unezidingo ezikhethekile, sizozama konke okusemandleni ethu ukuze sizifake.

Ngokuya ngobuningi, isikhathi sethu sokulethwa sihlukile. Kodwa sithembisa ukuthumela ngokushesha ngangokunokwenzeka ngekhwalithi eqinisekisiwe.

Yebo, sinikeza amasampula mahhala.

Yebo, kunjalo, wamukelekile ukuvakashela inkampani ye-RBT kanye nemikhiqizo yethu.

Awukho umkhawulo, singakunikeza isiphakamiso esihle kakhulu nesixazululo ngokuya ngesimo sakho.

Sesineminyaka engaphezu kwengu-30 senza izinto eziphikisayo, sinokusekela okuqinile kwezobuchwepheshe kanye nesipiliyoni esicebile, singasiza amakhasimende akhe amahhanisi ahlukene futhi anikeze isevisi yokuma okukodwa.