1. Ingaphoswa nge-aluminium ephezulu:I-castable ye-aluminium ephezulu yakhiwe kakhulu nge-alumina (Al2O3) futhi inokumelana okuphezulu, ukumelana nokugqwala kanye nokumelana nokushaqeka kokushisa. Isetshenziswa kabanzi ezithandweni zokushisa okuphezulu nasezindaweni zokushisa ensimbi, izinsimbi ezingezona i-ferrous, amakhemikhali kanye neminye imboni.

2. I-castable yensimbi eqiniswe ngefayibha:I-castable eqiniswe ngefayibha yensimbi isekelwe kuma-castable ajwayelekile futhi amafayibha ensimbi ayengezwa ukuze kuthuthukiswe ukumelana kwayo nokushisa, ukumelana nokuguguleka kanye nokumelana nokulahlwa. Isetshenziswa kakhulu ezithandweni, ezinqeni zesithando nakwezinye izingxenye embonini yensimbi, i-metallurgy, i-petrochemical kanye neminye imboni.

3. Ingaphoswa nge-Mullite:I-Mullite castable yakhiwe kakhulu nge-mullite (MgO·SiO2) futhi inokumelana okuhle nokuguguleka, ukumelana nokugqwala kanye nokumelana nokungagqwali. Ivame ukusetshenziswa ezingxenyeni ezibalulekile njengezitofu zokwenza insimbi kanye neziguquli ensimbi, ensimbini nakwezinye izimboni.

4. I-silicon carbide ephothwayo:I-silicon carbide castable yakhiwe kakhulu yi-silicon carbide (SiC) futhi inokumelana okuhle kakhulu nokuguguleka, ukumelana nokugqwala kanye nokumelana nokushaqeka kokushisa. Isetshenziswa kabanzi ezithandweni zokushisa okuphezulu, emibhedeni yezithando nakwezinye izingxenye zezinsimbi ezingezona i-ferrous, amakhemikhali, izinto zobumba kanye neminye imboni.

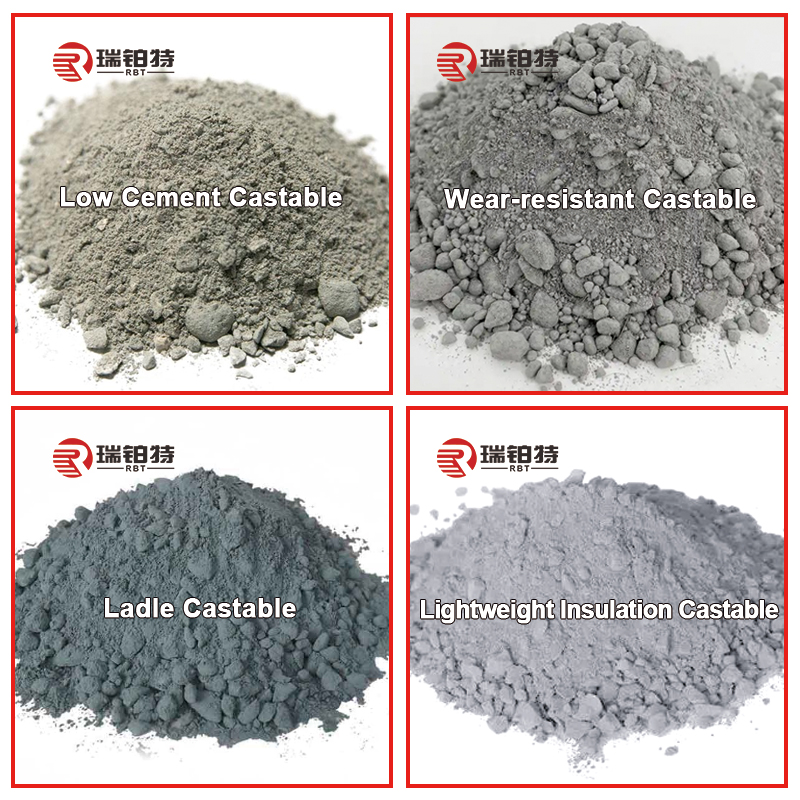

5. Izinto zokulahla ezingasetshenziswa ngosimende ophansi:Kubhekiselwa kuma-castable anokuqukethwe okuphansi kwesimende, okuvame ukuba ngu-5%, kanti amanye aze ancishiswe abe ngu-1% kuya ku-2%. Ama-castable asimende ophansi asebenzisa izinhlayiya ezincane kakhulu ezingadluli ku-1μm, futhi ukumelana kwawo nokushaqeka kokushisa, ukumelana nokugqwala kanye nokumelana nokuguguleka komhlabathi kuthuthukiswa kakhulu. Ama-castable asimende ophansi afanelekela ama-linings ezinhlobo ezahlukene zokushisa, ama-heater, ama-holn aqondile, ama-rotary kiln, izembozo zesithando sikagesi, imigodi yokuthinta isithando sikagesi, njll.; ama-castable asimende ophansi azimele afanelekela ama-linings e-spray gun ahlanganisiwe e-spray metallurgy, ama-linings amelana nokuguguleka okushisa okuphezulu kwama-reactor e-catalytic cracking, kanye nama-linings angaphandle amapayipi okupholisa amanzi esithando sikagesi.

6. Izinto zokulahla ezingagugi ezingagugi:Izingxenye eziyinhloko zezinsimbi ezivikela ukuguguleka zifaka phakathi ama-aggregates avimbela ukuguguleka, izimpushana, izithasiselo kanye nama-binder. Izinsimbi ezivikela ukuguguleka ezivimbela ukuguguleka luhlobo lwezinto ezivimbela ukuguguleka ezingasetshenziswa kabanzi ekusetshenzisweni kwensimbi, amakhemikhali kaphethroli, izinto zokwakha, amandla kanye neminye imboni. Le nto inezinzuzo zokumelana nokushisa okuphezulu, ukumelana nokuguguleka, kanye nokumelana nokuguguleka. Isetshenziselwa ukulungisa nokuvikela ulwelwesi lwemishini evikela ukushisa okuphezulu njengezitofu nama-boiler ukwandisa impilo yenkonzo yemishini.

7. Ingilazi ephoswayo:I-Ladle castable iyi-castable engaphikisi kahle eyenziwe nge-clinker ye-bauxite ephezulu ye-alumina kanye ne-silicon carbide njengezinto eziyinhloko, ene-aluminate cement binder emsulwa, i-dispersant, i-ejenti enganciphisi, i-coagulant, i-fiber engaqhumi nezinye izithasiselo. Ngenxa yokuthi inomphumela omuhle engqimbeni yokusebenza ye-ladle, ibizwa nangokuthi i-aluminium silicon carbide castable.

8. I-castable elula yokuvikela engaphikisi:I-castable evikelayo engasindi i-castable evimbelayo engasindi i-castable evimbelayo enesisindo esincane, amandla aphezulu kanye nokusebenza kahle kakhulu kokuvikela ukushisa. Yakhiwe kakhulu ngama-aggregates alula (njenge-perlite, i-vermiculite, njll.), izinto ezizinzile ezishisa kakhulu, ama-binder kanye nezithasiselo. Isetshenziswa kabanzi emishinini ehlukahlukene yezimboni eshisa kakhulu, njengezitofu zezimboni, izitofu zokwelapha ukushisa, izitofu zensimbi, izitofu ezincibilikisa ingilazi, njll., ukuthuthukisa ukusebenza kahle kokusetshenziswa kwamandla kwemishini nokunciphisa ukusetshenziswa kwamandla.

9. I-Corundum ephoswayo:Ngenxa yokusebenza kwayo okuhle kakhulu, i-corundum castable isibe yisinqumo esifanele sezingxenye ezibalulekile zama-thermal kiln. Izici ze-corundum castable amandla aphezulu, izinga lokushisa eliphakeme lokuthambisa umthwalo kanye nokumelana okuhle kwe-slag, njll. Izinga lokushisa elijwayelekile lokusetshenziswa lingu-1500-1800℃.

10. I-Magnesium engasetshenziswa:Isetshenziswa kakhulu emishinini yokushisa eshisa kakhulu, inokumelana okuhle kakhulu nokugqwala kwe-alkaline slag, inkomba ephansi ye-oxygen potential futhi ayinakho ukungcola kwensimbi encibilikisiwe. Ngakho-ke, inezinhlobo eziningi zamathemba okusetshenziswa embonini yensimbi, ikakhulukazi ekukhiqizweni kwensimbi ehlanzekile kanye nemboni yezinto zokwakha.

11. Ubumba oluphoswayo:Izingxenye eziyinhloko yi-clay clinker kanye nobumba oluhlanganisiwe, olunokuqina okuhle kokushisa kanye nokuphikiswa okuthile, futhi intengo iphansi kakhulu. Ivame ukusetshenziswa elangeni lama-oven ajwayelekile ezimboni, njengezitofu zokushisa, izitofu zokufaka umoya, ama-boiler, njll. Ingamelana nokushisa okuthile futhi idlale indima ekuvikeleni ukushisa nasekuvikeleni umzimba wesitofu.

12. Izinto zokulahla ezomile:Izinto zokulahla ezomile zakhiwe kakhulu yizinto ezixubile, izimpushana, izihlanganisi namanzi. Izithako ezivamile zifaka phakathi i-clay clinker, i-tertiary alumina clinker, i-ultrafine powder, i-CA-50 cement, ama-dispers kanye nezinto ezingenakungenwa yi-siliceous noma i-feldspar.

Ama-castable omile angahlukaniswa ngezinhlobo eziningi ngokuya ngokusetshenziswa kwawo kanye nezithako zawo. Isibonelo, ama-castable omile angangeniswa amanzi asetshenziswa kakhulu kumaseli e-aluminium electrolytic, angavimbela ngempumelelo ukungena kwama-electrolyte futhi andise impilo yenkonzo yamaseli. Ngaphezu kwalokho, ama-castable omile angaguquki afaneleka kwihadiwe, ukuncibilikisa, imboni yamakhemikhali, izinsimbi ezingezona insimbi kanye neminye imboni, ikakhulukazi embonini yensimbi, njengomlomo we-rotary kiln front kiln, isithando sokudilika, isembozo sekhanda le-kiln kanye nezinye izingxenye.

Isikhathi sokuthunyelwe: Meyi-26-2025