Izidingo ezijwayelekile zezinto eziphikisayo zezitofu zikagesi ze-arc yilezi:

(1) Ukungazweli kahle kufanele kube phezulu. Izinga lokushisa le-arc lidlula u-4000°C, kanti izinga lokushisa lokwenza insimbi lingu-1500~1750°C, ngezinye izikhathi liphakeme njengo-2000°C, ngakho-ke izinto zokungazweli kahle ziyadingeka ukuze zibe nokungazweli okuphezulu.

(2) Izinga lokushisa lokuthambisa ngaphansi komthwalo kufanele libe phezulu. Isithando sikagesi sisebenza ngaphansi kwezimo zomthwalo wokushisa okuphezulu, futhi umzimba wesithando kufanele umelane nokuguguleka kwensimbi encibilikisiwe, ngakho-ke izinto eziphikisayo ziyadingeka ukuze zibe nezinga lokushisa eliphezulu lokuthambisa umthwalo.

(3) Amandla okucindezela kufanele abe phezulu. Ulwelwesi lwesithando sikagesi luthintwa umthelela wokushaja ngesikhathi sokushaja, ingcindezi engaguquki yensimbi encibilikisiwe ngesikhathi sokuncibilikisa, ukuguguleka kokugeleza kwensimbi ngesikhathi sokuthepha, kanye nokudlidliza komshini ngesikhathi sokusebenza. Ngakho-ke, izinto eziphikisayo ziyadingeka ukuze zibe namandla aphezulu okucindezela.

(4) Ukushisa kufanele kube kuncane. Ukuze kuncishiswe ukulahleka kokushisa kwesithando sikagesi futhi kuncishiswe ukusetshenziswa kwamandla, izinto eziphikisayo ziyadingeka ukuze zibe nokushisa okubi, okungukuthi, i-coefficient yokushisa kufanele ibe ncane.

(5) Ukuqina kokushisa kufanele kube kuhle. Phakathi nemizuzu embalwa kusukela ekucindezelweni kuya ekushajeni ekwenzeni insimbi yesithando sikagesi, izinga lokushisa lehla kakhulu kusukela cishe ku-1600°C kuya ngaphansi kuka-900°C, ngakho-ke izinto eziphikisayo ziyadingeka ukuze kube nokuqina okuhle kokushisa.

(6) Ukumelana nokugqwala okunamandla. Ngesikhathi senqubo yokwenza insimbi, i-slag, igesi yesithando kanye nensimbi encibilikisiwe konke kunemiphumela enamandla yokuguguleka kwamakhemikhali ezintweni eziphikisayo, ngakho-ke izinto eziphikisayo ziyadingeka ukuze zibe nokumelana okuhle nokugqwala.

Ukukhethwa kwezinto eziphikisayo zezindonga eziseceleni

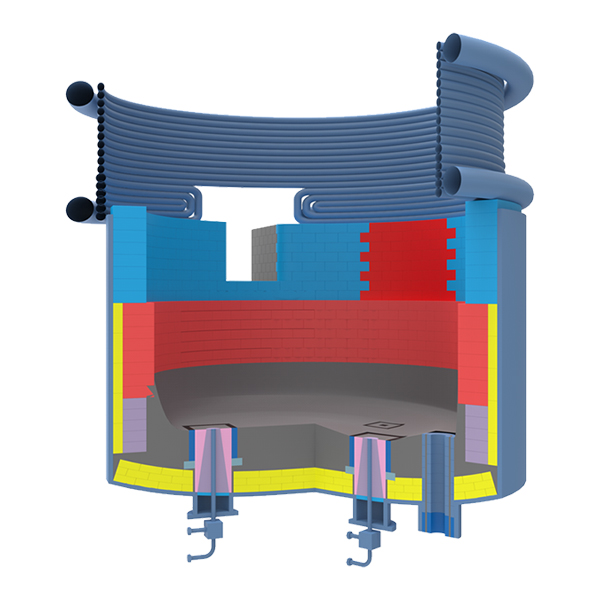

Izitini ze-MgO-C zivame ukusetshenziselwa ukwakha izindonga eziseceleni zezitofu zikagesi ngaphandle kwezindonga zokupholisa amanzi. Izindawo ezishisayo kanye nemigqa ye-slag inezimo zesevisi ezinzima kakhulu. Azigcini nje ngokugqwala kakhulu futhi ziguguleke yinsimbi encibilikisiwe kanye ne-slag, kanye nokuthinteka kakhulu ngomshini lapho kufakwa izinsalela, kodwa futhi zibhekene nemisebe yokushisa evela ku-arc. Ngakho-ke, lezi zingxenye zakhiwe ngezitini ze-MgO-C ezisebenza kahle kakhulu.

Ezindongeni eziseceleni zezitofu zikagesi ezinezindonga ezipholiswe ngamanzi, ngenxa yokusetshenziswa kobuchwepheshe bokupholisa amanzi, umthwalo wokushisa uyakhuphuka futhi izimo zokusebenzisa ziqinile kakhulu. Ngakho-ke, kufanele kukhethwe izitini ze-MgO-C ezinokumelana okuhle kwe-slag, ukuqina kokushaqeka kokushisa kanye nokuqhuba okuphezulu kokushisa. Okuqukethwe kwazo kwekhabhoni kungu-10% ~ 20%.

Izinto ezivuselelayo zezindonga eziseceleni zezitofu zikagesi ezinamandla aphezulu kakhulu

Izindonga eziseceleni zezitofu zikagesi ezinamandla aphezulu kakhulu (izitofu ze-UHP) zakhiwe kakhulu ngezitini ze-MgO-C, kanti izindawo ezishisayo nezindawo zomugqa we-slag zakhiwe ngezitini ze-MgO-C ezisebenza kahle kakhulu (njengezitini ze-MgO-C ezigcwele ikhabhoni). Zithuthukisa kakhulu impilo yazo yokusebenza.

Nakuba umthwalo wodonga lwesithando somlilo unciphile ngenxa yokuthuthukiswa kwezindlela zokusebenza kwesithando somlilo sikagesi, kusenzima ngezinto ezimelana nokushisa ukwandisa impilo yesevisi yezindawo ezishisayo lapho zisebenza ngaphansi kwezimo zokuncibilikisa isithando somlilo se-UHP. Ngakho-ke, ubuchwepheshe bokupholisa amanzi buthuthukisiwe futhi busetshenziswa. Kuma-furnace kagesi asebenzisa i-EBT tapping, indawo yokupholisa amanzi ifinyelela ku-70%, ngaleyo ndlela kunciphisa kakhulu ukusetshenziswa kwezinto ezimelana nokushisa. Ubuchwepheshe besimanje bokupholisa amanzi budinga izitini ze-MgO-C ezinokushisa okuhle. I-asphalt, izitini ze-magnesia eziboshwe yi-resin kanye nezitini ze-MgO-C (okuqukethwe kwekhabhoni okungu-5%-25%) zisetshenziselwa ukwakha izindonga eziseceleni zesithando somlilo sikagesi. Ngaphansi kwezimo ezinzima ze-oxidation, ama-antioxidants ayengezwa.

Ezindaweni ezishisayo ezonakele kakhulu yi-redox reactions, kusetshenziswa izitini ze-MgO-C ezine-crystalline fused magnesite enkulu njengezinto zokusetshenziswa, okuqukethwe kwekhabhoni okungaphezu kuka-20%, kanye ne-full carbon matrix ekwakheni.

Intuthuko yakamuva yezitini ze-MgO-C zezitofu zikagesi ze-UHP ukusebenzisa ukudubula okushisa okuphezulu bese kufakwa i-asphalt ukukhiqiza okuthiwa izitini ze-MgO-C ezifakwe i-asphalt. Njengoba kungabonakala kuThebula 2, uma kuqhathaniswa nezitini ezingafakwanga, okuqukethwe kwekhabhoni okusele kwezitini ze-MgO-C ezifakwe i-asphalt ngemva kokufakwa kwe-asphalt kanye nokufakwa kabusha kwe-carbon kuyanda cishe ngo-1%, i-porosity yehla ngo-1%, futhi amandla okuguquguquka kokushisa okuphezulu kanye nokumelana nengcindezi. Amandla athuthukiswe kakhulu, ngakho-ke aqinile kakhulu.

Izinto ezivimbela i-magnesium zezindonga eziseceleni zesithando sikagesi

Izindwangu zesithando sikagesi zihlukaniswe zibe yi-alkaline kanye ne-acidic. Eyokuqala isebenzisa izinto eziphikisayo ze-alkaline (njenge-magnesia kanye nezinto eziphikisayo ze-MgO-CaO) njengendwangu yesithando, kanti eyesibili isebenzisa izitini ze-silica, isihlabathi se-quartz, udaka olumhlophe, njll. ukwakha ulwelwesi lwesithando.

Qaphela: Ngezinto zokwakha uthango lwesithando, izithando zikagesi ze-alkaline zisebenzisa izinto zokuphikisa i-alkaline, kanti izithando zikagesi ze-acidic zisebenzisa izinto zokuphikisa i-acid.

Isikhathi sokuthunyelwe: Okthoba-12-2023